A visual test device for horizontal non-uniform indirect heating rectangular channel flow

A test device and a technology of rectangular channels, which are applied in the fields of climate sustainability, nuclear reactor monitoring, and reduction of greenhouse gases, etc., can solve the problems that it is difficult to popularize rectangular channels, and it is impossible to apply horizontal non-uniform heating to experimental research on the flow and heat transfer characteristics of rectangular channels. Achieve the effect of ensuring integrity, meeting the requirements of test conditions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in detail:

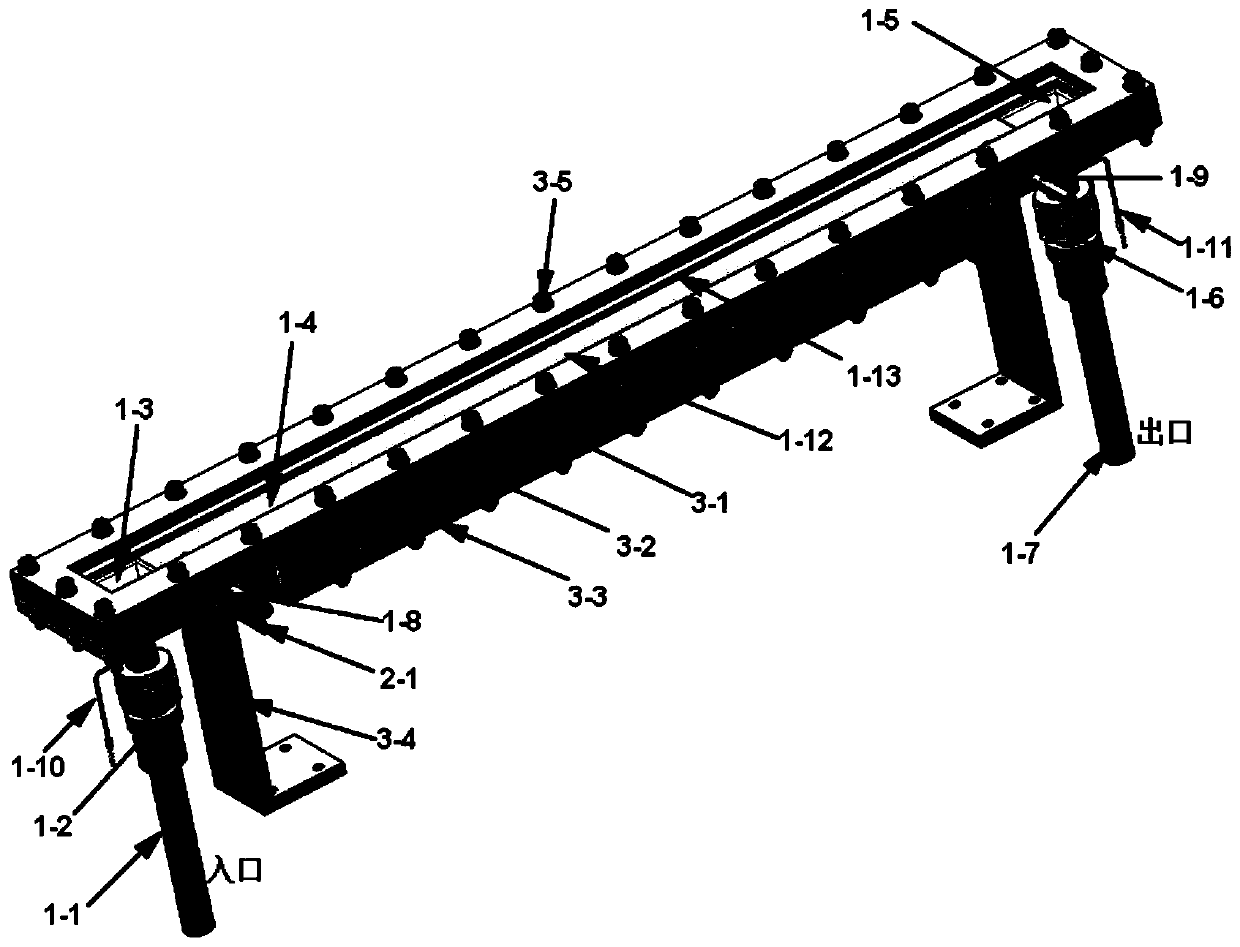

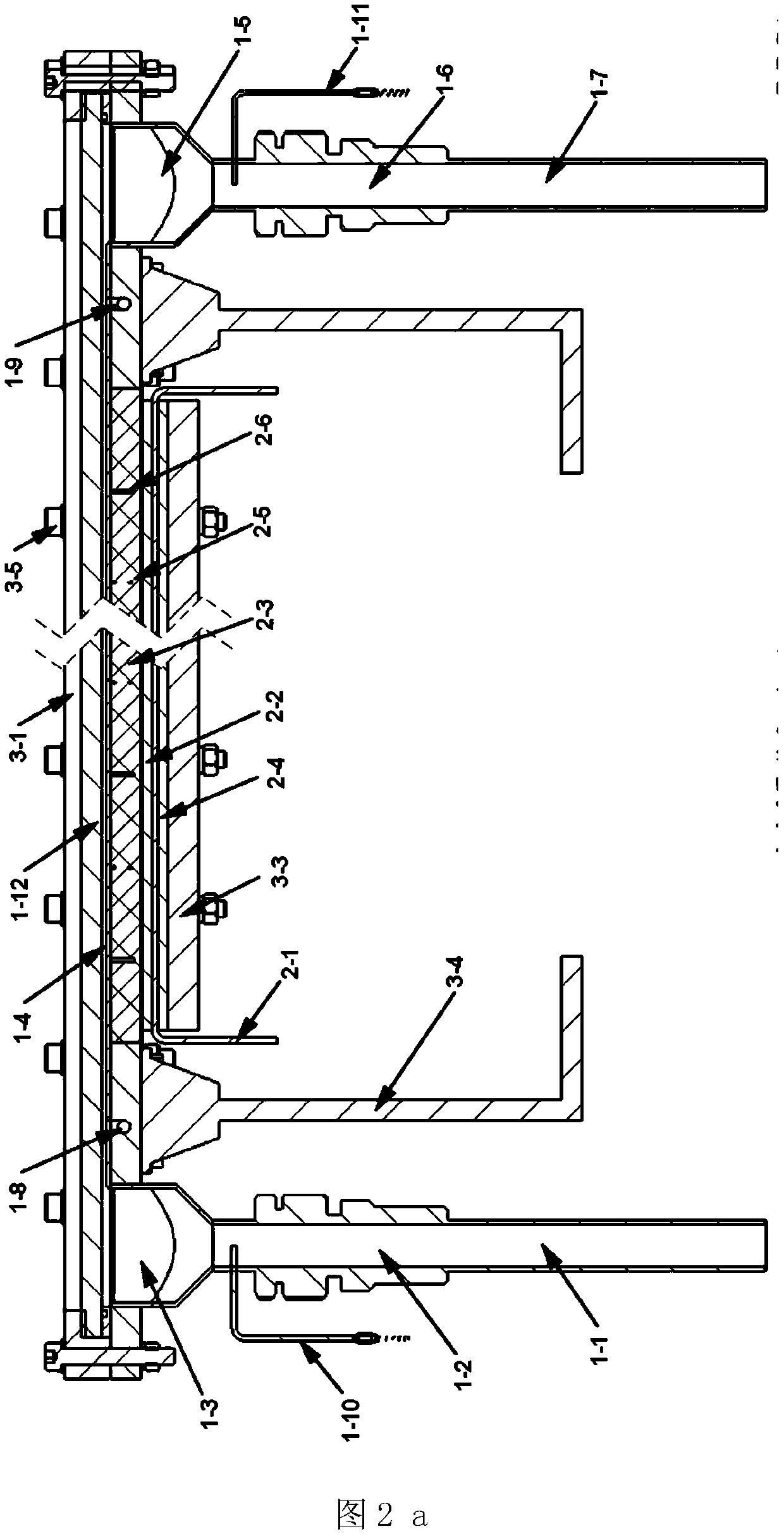

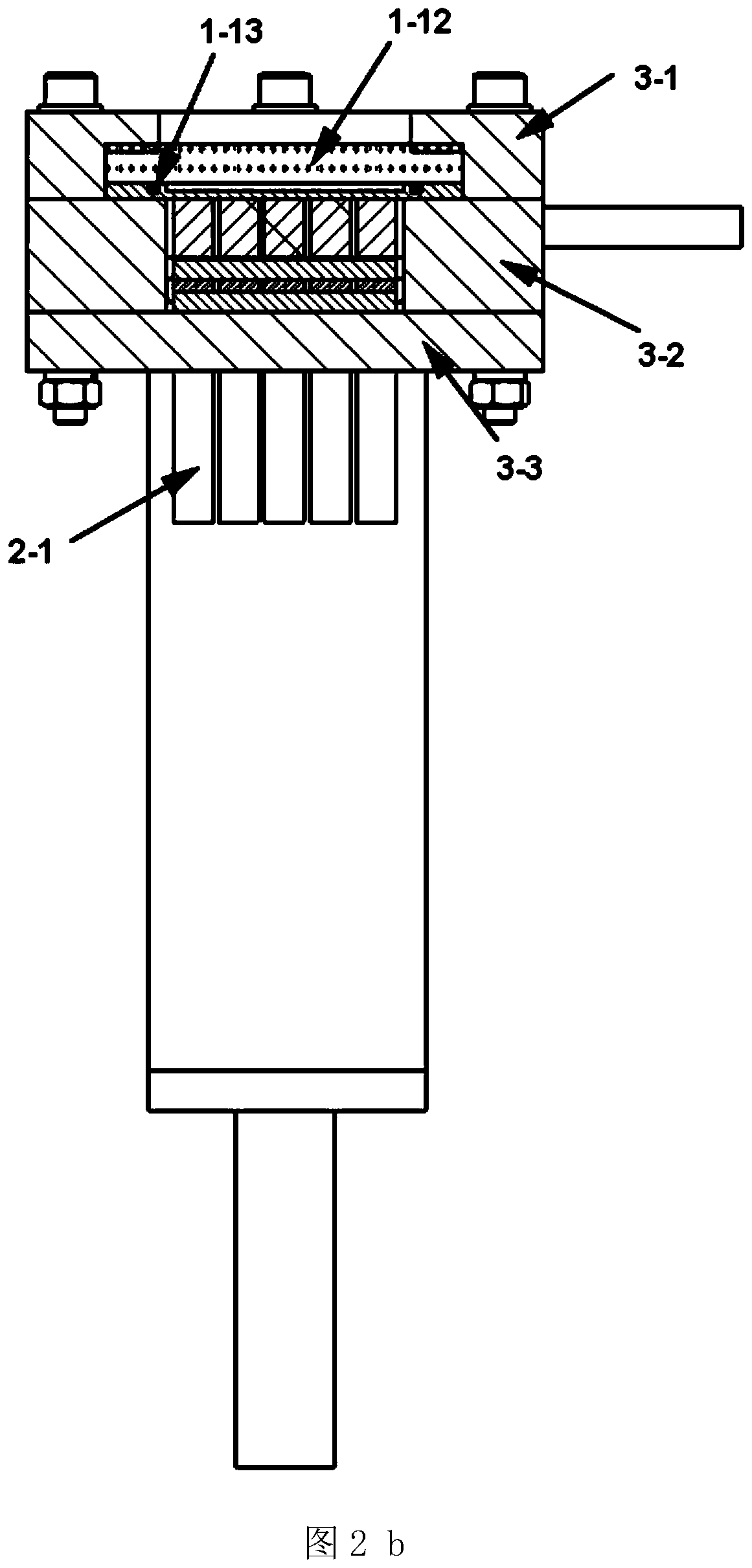

[0033] like figure 1 and figure 2 middle figure 2 a and figure 2 As shown in b, the present invention is a horizontal non-uniform indirect heating rectangular channel flow visualization test device. The test device is generally a rectangular axisymmetric structure, and is composed of a flow channel body module, a power loading module and a clamping and fixing module; the flow The channel body module consists of a cylindrical inlet connection 1-1, an inlet ferrule 1-2, an inlet chamber 1-3, a rectangular flow channel unit 1-4, an outlet chamber 1-5, an outlet ferrule 1-6 and a cylindrical Outlet connecting pipe 1-7, visualization window 1-12, sealing ring 1-13, composed of, wherein the inlet ferrule 1-2 is respectively connected and sealed with the cylindrical inlet connecting pipe 1-1 and the inlet chamber 1-3 through threads; Yes, the outlet ferrule 1-6 is threaded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com