Coaxial cable with high phase stability performance and preparation method thereof

A coaxial cable, phase stabilization technology, applied in the direction of coaxial cable/analog cable, cable/conductor manufacturing, insulated cable, etc., can solve the problem of coaxial cable, signal transmission deviation, cable phase fluctuation, etc. problem, to achieve the effect of good temperature stability phase stability, temperature phase stability, small standing wave change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

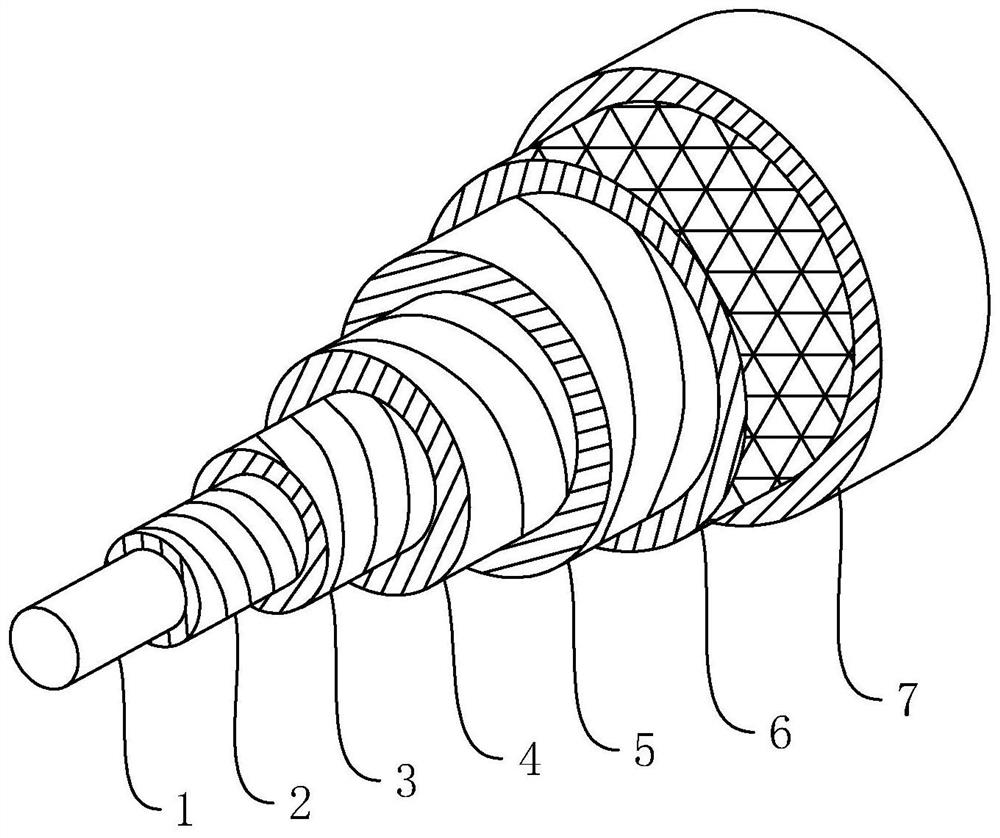

[0041] High phase stability coaxial cables, such as figure 1 As shown, it includes a central conductor 1, an insulating dielectric layer 2, an inner shielding layer 3, a first intermediate layer 4, a second intermediate layer 5, an outer shielding layer 6, and a sheath layer 7 arranged coaxially from the inside to the outside;

[0042] Among them, the central conductor 1 is a silver-plated copper stranded conductor, the thickness of the silver-plated layer is 2 μm, and the insulating medium layer 2 is a microporous polytetrafluoroethylene wrapping tape, which is wound outside the center conductor 1 through a wrapping process; the inner shielding layer 3 is Silver-plated copper wrapping tape, the thickness of the silver layer of silver-plated copper is 2 μm; the inner shielding layer 3 is wound on the insulating medium layer 2 through the wrapping process; the first intermediate layer 4 is polyetheretherketone film, which is wound on the Inner Shield 3.

[0043] The microporou...

Embodiment 2

[0058] The difference between Example 2 and Example 1 of the coaxial cable with high phase stability is that the sintering-resistant solid PTFE film is not sintered after winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap