Assembly for measuring torque and/or axial load for capping heads

An axial load and cover head technology, applied in the field of torque and/or axial load components, can solve the problems of abnormal measurement, false rotational moment, measurement error, etc., and achieve the effect of highly accurate measurement, stable measurement and repeatable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following description, in order to describe the drawings, the same reference numerals are used to denote structural elements having the same function. Also, for the sake of clarity, some reference numerals may not be shown in all drawings.

[0062] Expressions such as "vertical" and "horizontal", "upper" and "lower" (in the absence of further indications) shall refer to installation (or operating) conditions and to normal terms used in the current language, where "vertical" means The direction of the gravity vector "g" is substantially parallel to the direction, and "horizontal" means the direction perpendicular to the vertical direction.

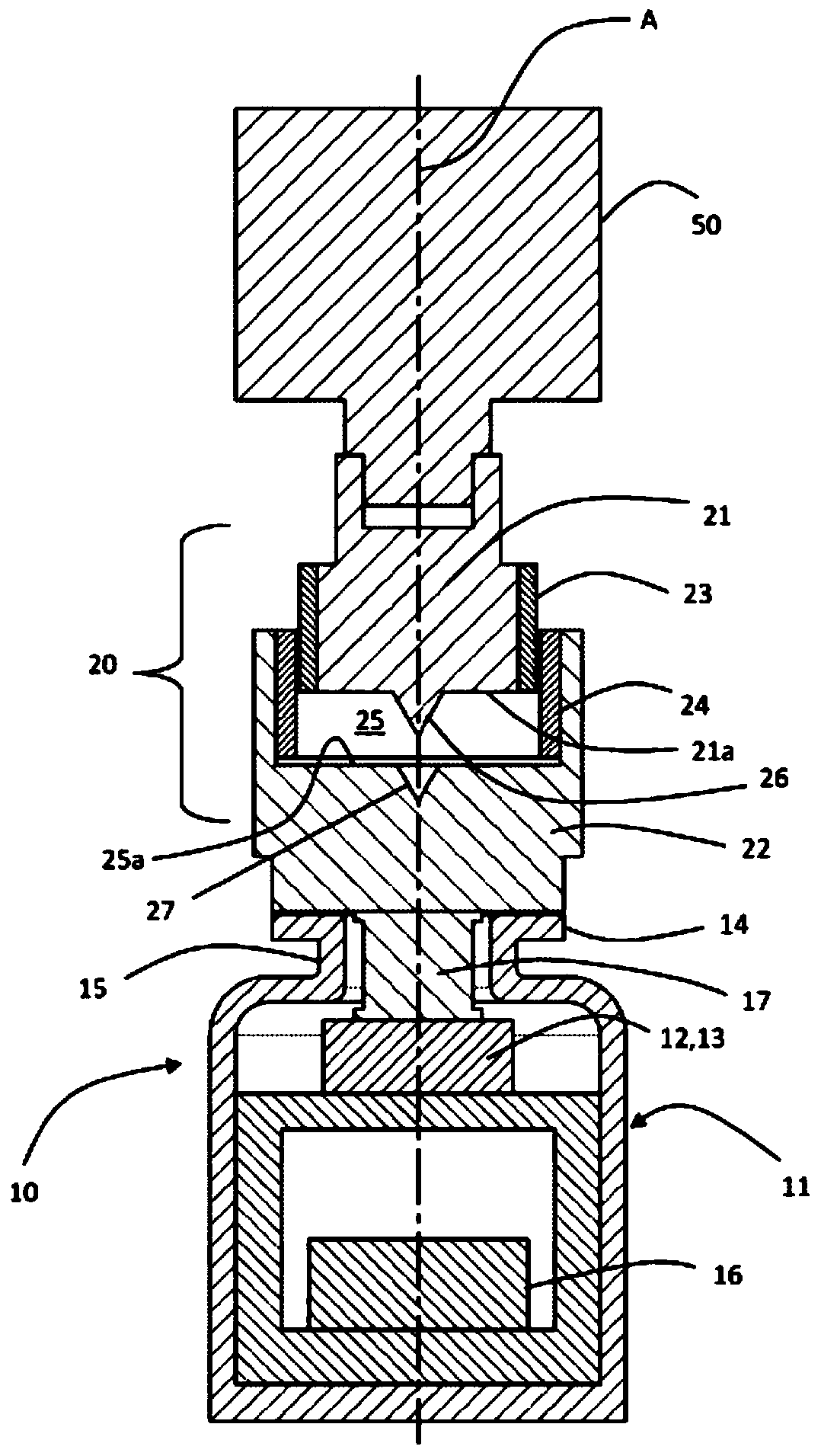

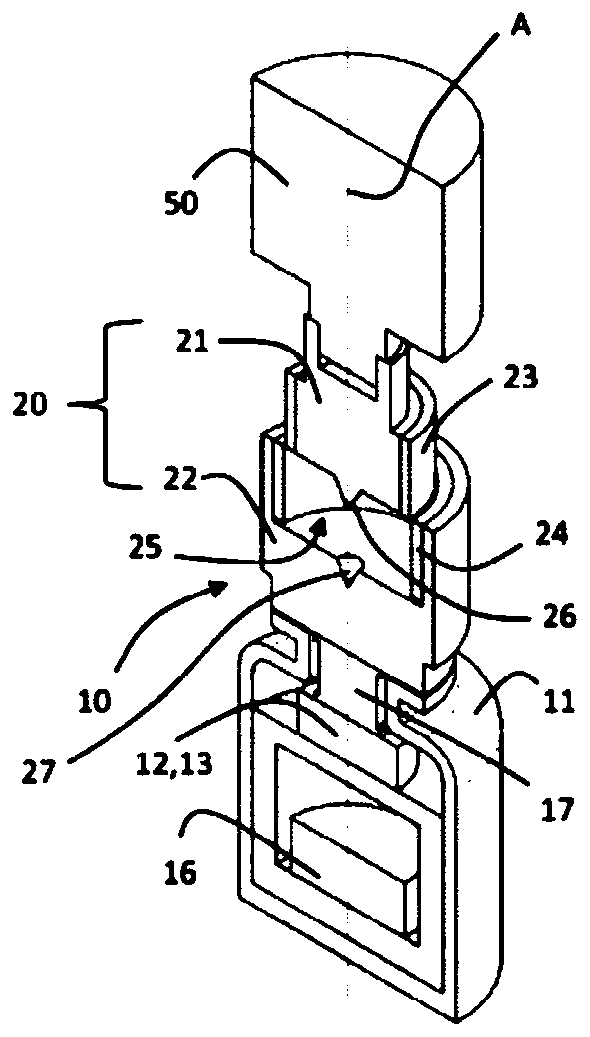

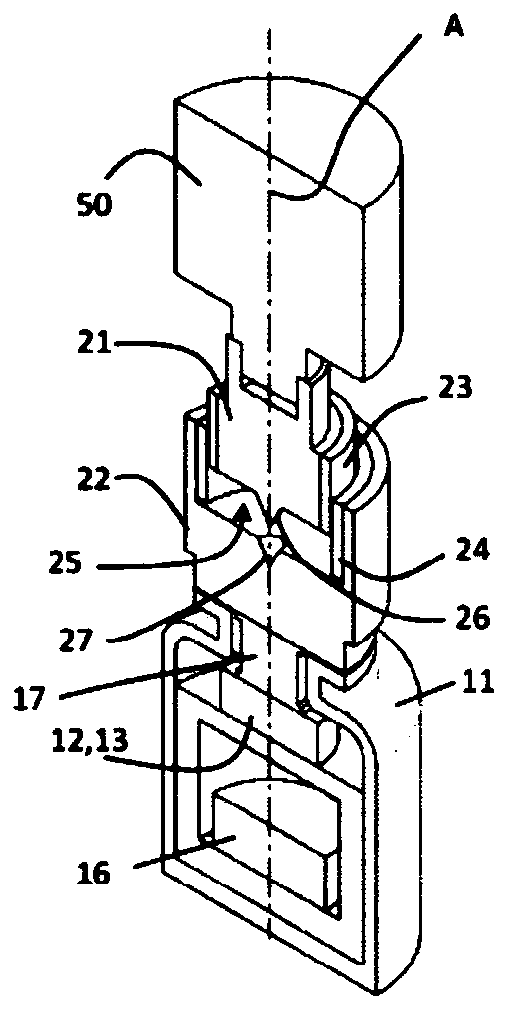

[0063] refer to figure 1 , which shows a first preferred embodiment of an assembly for measuring torque and / or axial load of a capping head according to the invention, said assembly generally indicated at 10 .

[0064] The measuring assembly 10 comprises a housing body 11 preferably having the outer shape of a bottle or cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com