Revolving door assembly and container therewith

A container and revolving door technology, applied in the field of cargo transportation equipment, can solve the problems of high logistics turnover cost and low utilization rate of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

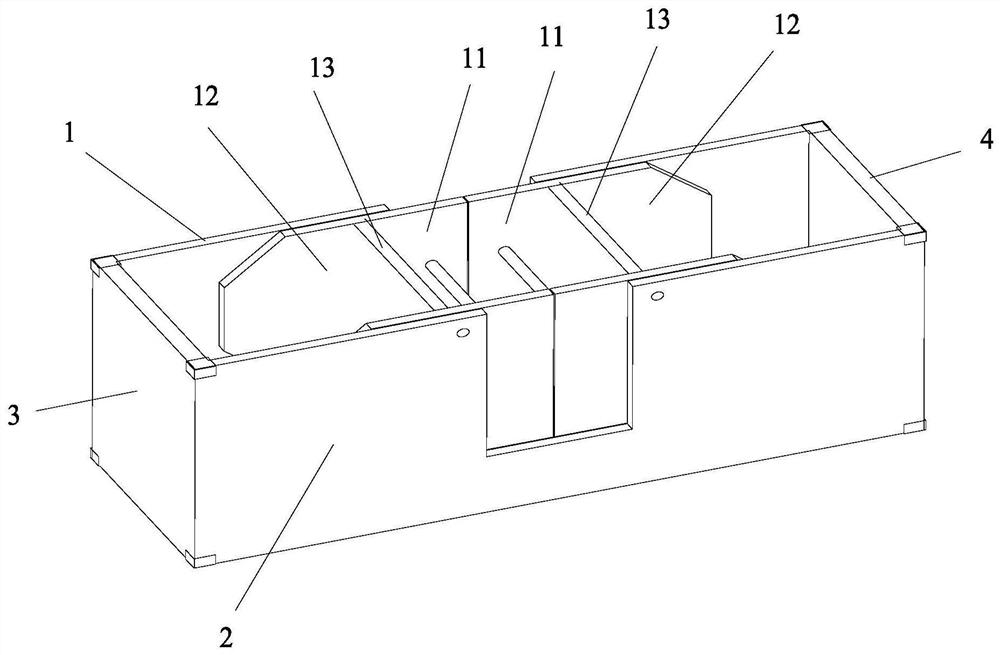

[0030] Such as figure 1 As shown, Embodiment 1 of the present invention provides a revolving door assembly, which is arranged on a container with an opening for opening or closing the opening. The revolving door assembly of this embodiment includes a door panel body 11 . The door panel body 11 is rotatably arranged, and the door panel body 11 has an avoidance position for opening the opening and a stop position for closing the opening; wherein, when the coiled material 20 is shipped in the container, the door panel body 11 is located at the avoidance position, so that the hoisting equipment or The forklift equipment extends through the opening to load and unload the materials in the container; when the container is carrying granular materials 30 , the door panel body 11 is at the stop position so that the container is carrying granular materials 30 .

[0031] In this embodiment, since the door panel body 11 is rotatably arranged, the opening of the container can be switched be...

Embodiment 2

[0061] The difference between the second embodiment and the first embodiment is:

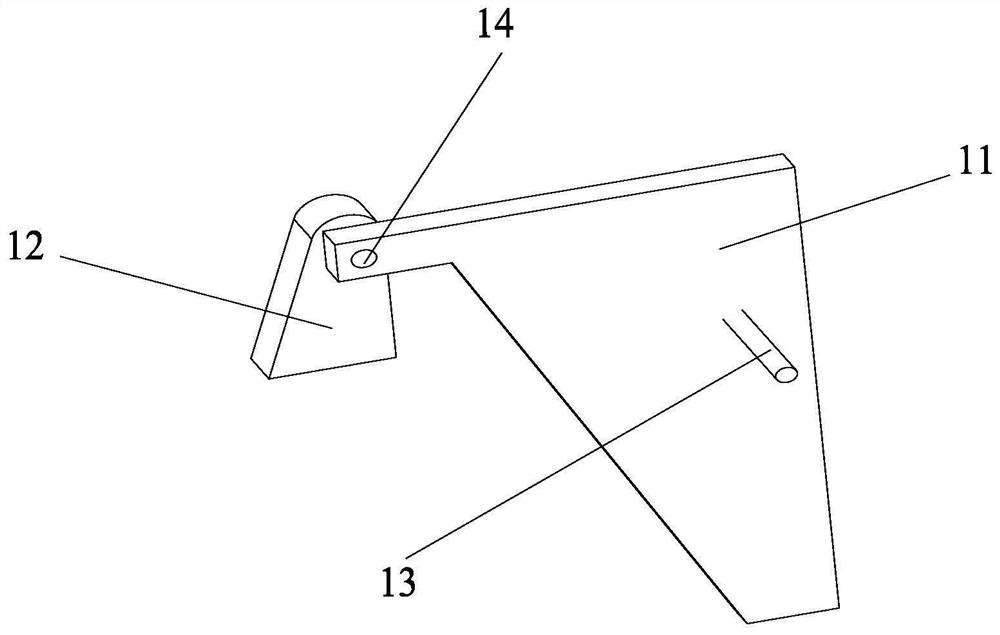

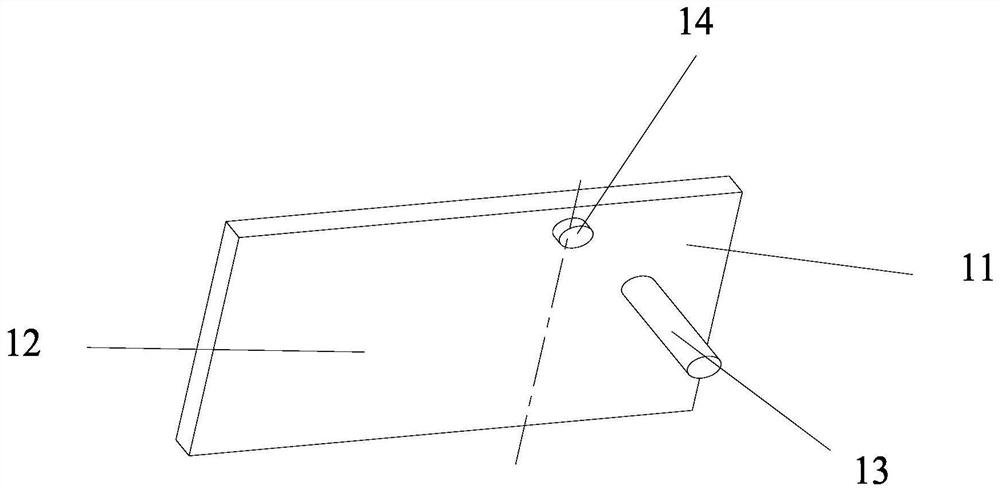

[0062] Such as figure 2 As shown, in the second embodiment, the revolving door assembly also includes a rotating shaft 14, the door panel body 11 rotates around the rotating shaft 14, the power part 12 is a counterweight, and the counterweight and the door panel body 11 are arranged on both sides of the rotating shaft 14, so as to Under the action of gravity of the counterweight, the door panel body 11 is kept at the stop position, or, under the action of gravity of the counterweight, the door panel body 11 is driven to rotate from the avoidance position to the stop position.

[0063] Specifically, the counterweight is connected to the rotating shaft 14. When the door panel body 11 is at the stop position, under the weight of the counterweight, the door panel body 11 remains at the stop position; when the container is loaded with coiled materials, The door panel body 11 rotates from the stop p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com