Sliding door assembly and container with sliding door assembly

A sliding door and container technology, applied in the field of cargo transportation equipment, can solve the problems of high logistics turnover cost and low container utilization rate, and achieve the effects of reducing logistics transportation costs, improving utilization rate, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

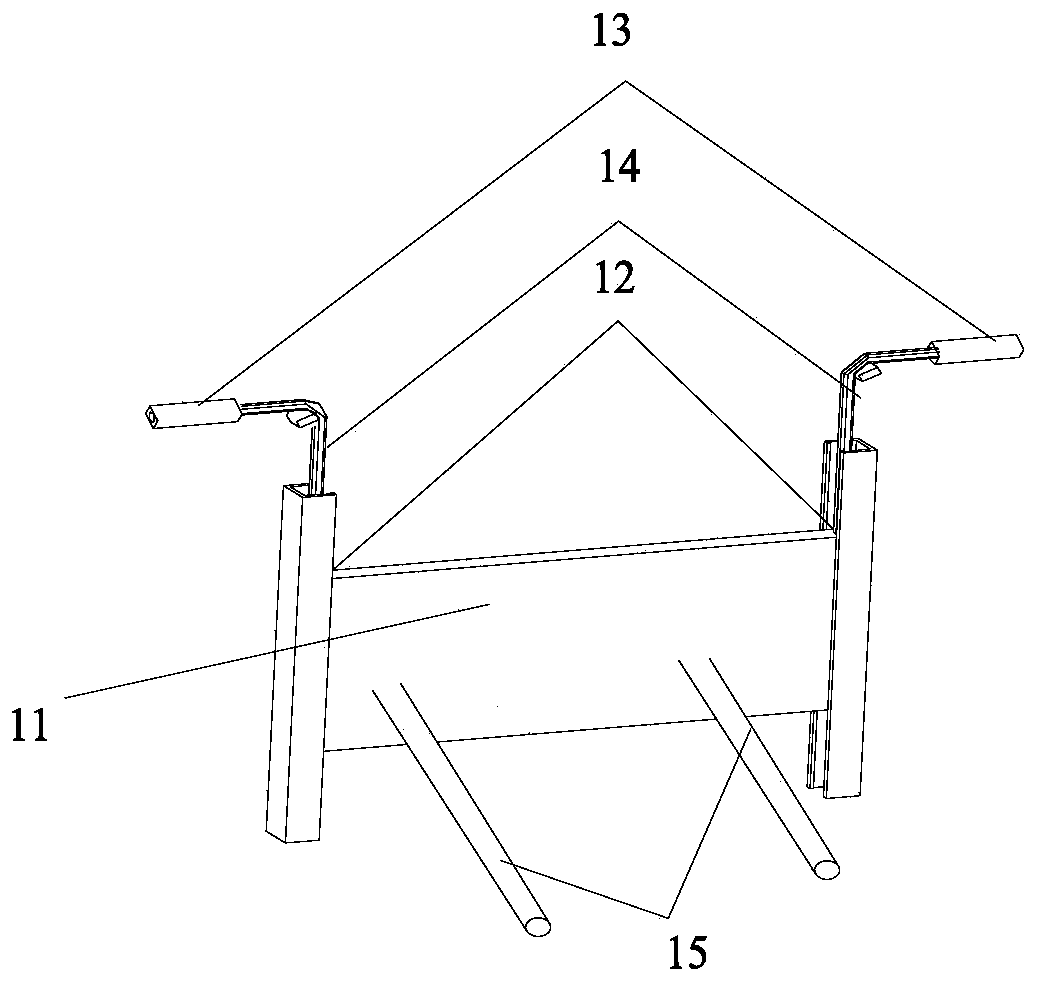

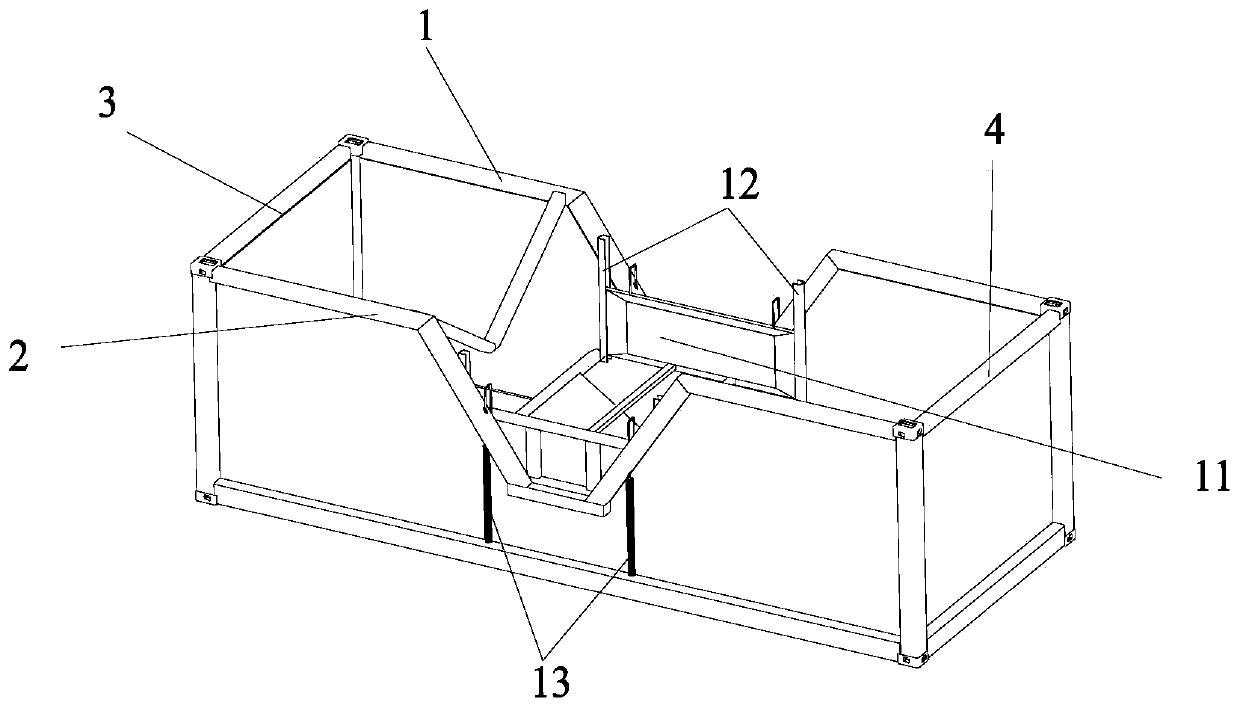

[0033] Such as figure 1 As shown, Embodiment 1 of the present invention provides a sliding door assembly, which is arranged on a container with an opening for opening or closing the opening. The sliding door assembly includes a door panel body 11, which is movably arranged, and the door panel body 11 has an avoidance position for opening the opening and a stop position for closing the opening; wherein, when the coiled material 20 is shipped in the container, the door panel body 11 is located at the avoidance position so that hoisting or forklift equipment can be inserted through the opening. , loading and unloading the materials located in the container;

[0034] In the first embodiment, since the door panel body 11 is movably arranged, the opening of the container can be switched between the open state and the closed state, so that the container can be loaded with different goods as required. The profile material 20 is convenient for hoisting equipment or forklift equipment ...

Embodiment 2

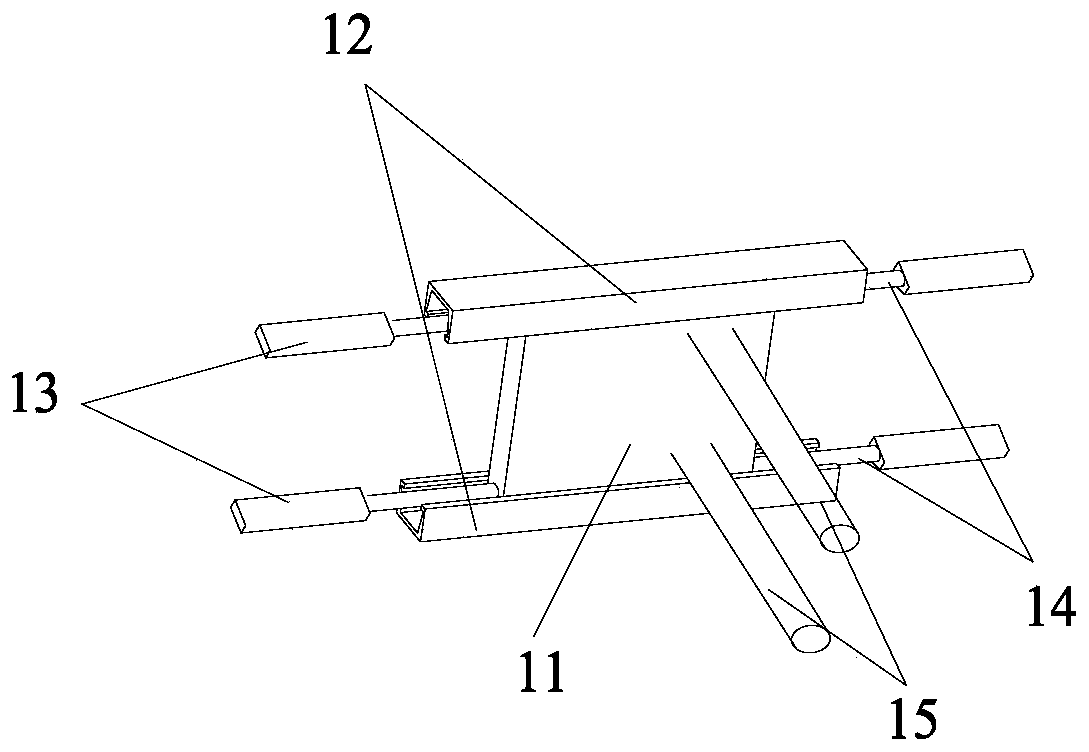

[0064] The difference between the second embodiment and the first embodiment is:

[0065] Such as figure 2 As shown, in the second embodiment, the sliding door assembly also includes a chute 12, along the height extension direction of the container, the chute 12 is arranged at the upper and lower ends of the door panel body 11, and the door panel body 11 is along the length of the container along the chute 12 It is movably arranged in the extending direction to open or close the opening.

[0066] Owing to being provided with chute 12, chute 12 is arranged on the upper and lower ends of door panel body 11, so that door panel body 11 can open or close opening on the length direction of container, and then when loading granular material, close opening, to prevent When the material leaks, when the coiled material 20 is shipped, the opening is opened to facilitate the operation of hoisting equipment or forklift equipment, and the coiled material 20 is loaded and unloaded.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com