Plate reversing arrangement device

A technology for reversing rows and plates, which is applied in the directions of transportation and packaging, conveyor objects, etc., to reduce labor intensity, facilitate detection, and improve efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

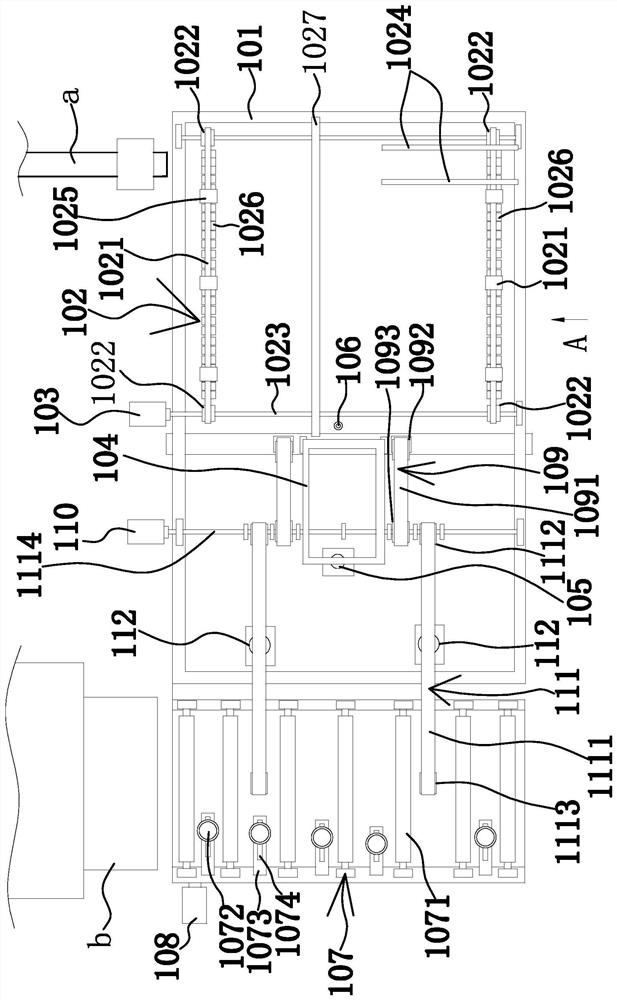

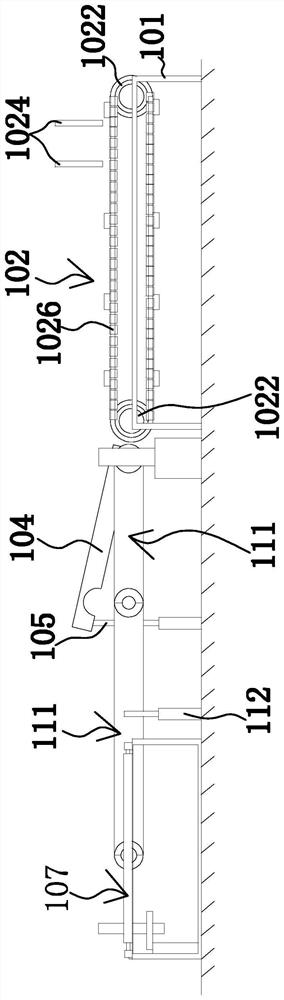

[0021] The board reversing and arranging device of the present invention is located between the veneer conveying device a and the packing device b that convey the single boards one by one, and includes a mounting frame 101, and is characterized in that: the arranging device also includes receiving The first conveying assembly 102 and the first driving member 103 connected thereto convey the plate conveyed by the conveying device a and convey the plate along a direction perpendicular to the conveying direction of the veneer conveying device a. The outer side is adjacent to a carrier 104 that can place a set number of plates side by side along the conveying direction of the first transport assembly 102. The carrier 104 is hinged on the mounting frame 101 near the side of the first transport assembly 102. 104 is also connected to the first lifting member 105 for controlling the lifting of the other side corresponding to the hinged side. The first lifting member 105 here can be but...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, the difference is that: the two sides extending along the conveying direction of the first conveying assembly 102 on the carrying frame 104 here are provided with a third conveying assembly for conveying the plates located on the carrying frame 104 109 and the third driver 110 connected thereto. The arrangement of the third conveying assembly 109 can facilitate the improvement of conveying efficiency and the enhancement of conveying stability when a set number of plates on the carrier 104 is moved to the second conveying assembly 107 .

[0031] Specifically, the third conveying assembly 109 includes a pair of first conveying belts 1091 extending along the conveying direction of the first conveying assembly 102 adjacent to the carriage 104, and Both sides of the transmission direction are respectively connected with the first pulley 1092 and the second pulley 1093 , and the second pulley 1093 is connected with the th...

Embodiment 3

[0033] This embodiment is basically the same as Embodiment 2, except that there is a set between the third conveying assembly 109 and the second conveying assembly 107 for transferring the set number of plates on the second conveying assembly 107 along the first conveying The transmission direction of the component 102 is the fourth transmission component 111, one side of the fourth transmission component 111 and one side of the third transmission component 109 are coaxially arranged and the third drive member 110 drives the fourth transmission component 111 and the third transmission component 111. The transmission assembly 109 carries out synchronous delivery, and the side corresponding to the above-mentioned side on the fourth transmission assembly 111 is a free side and goes deep into the second transmission assembly 107, and the fourth transmission assembly 111 is used to drive the fourth transmission assembly. In 111, the above-mentioned free-side lifting or lowering seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com