Sealing pair of dual-sealing-face valve, dual-sealing-face valve and application of dual-sealing-face valve serving as bypass valve

A valve sealing and sealing surface technology, which is applied in the field of double sealing surface valve sealing pairs, can solve problems such as the decline in the working capacity of the steam turbine, the increase in the exhaust temperature of the steam turbine, and the overheating of the tube wall temperature of the low-temperature reheater of the boiler, etc. Flexible and reliable, improved sealing performance, and reduced switching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

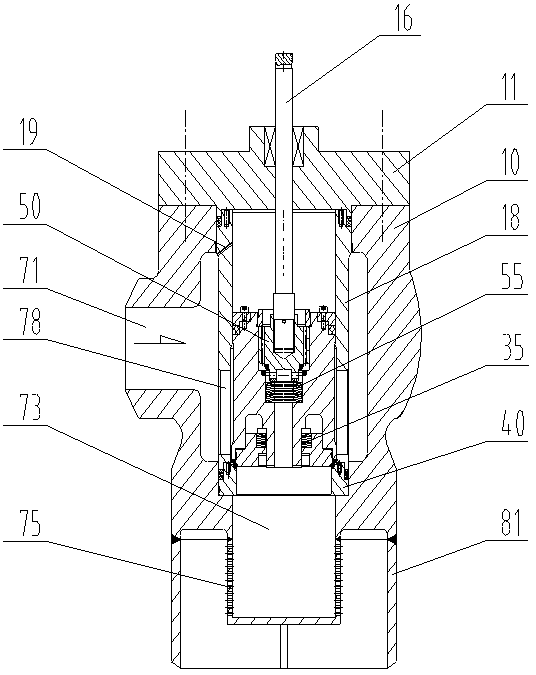

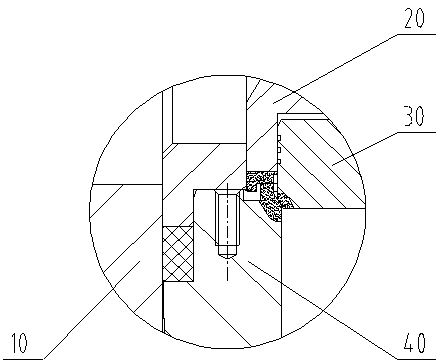

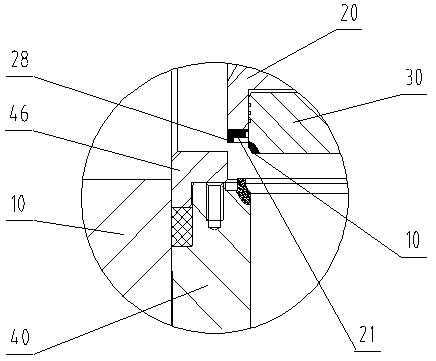

[0023] see Figure 1-5 , the present invention provides a double sealing surface valve sealing pair, which includes a valve seat 40 and a valve core, the valve seat is provided with a first sealing surface 41 and a second sealing surface 42, the first sealing surface of the valve seat Located on its upper end surface, it can be an annular plane, or an appropriate shape such as an annular arc surface. The second sealing surface of the valve seat is located on the upper part of the inner surface of the valve seat, preferably an annular conical surface, also It can be a suitable shape such as an annular protrusion. The valve core includes a first valve flap 20 and a second valve flap 30. The first valve flap is provided with a sealing surface 21, and the sealing surface of the first valve flap is located at Its lower end surface adopts a structure that matches the first sealing surface of the valve seat, and forms a first valve sealing pair with the first surface cover of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com