Thermal/vibration coupling test device of lightweight heat-proof material in 1700 DEG C extreme high temperature environment

A heat-resistant material and high-temperature environment technology, which is applied in the direction of measuring devices, material thermal development, and analyzing materials, to achieve good reliability and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

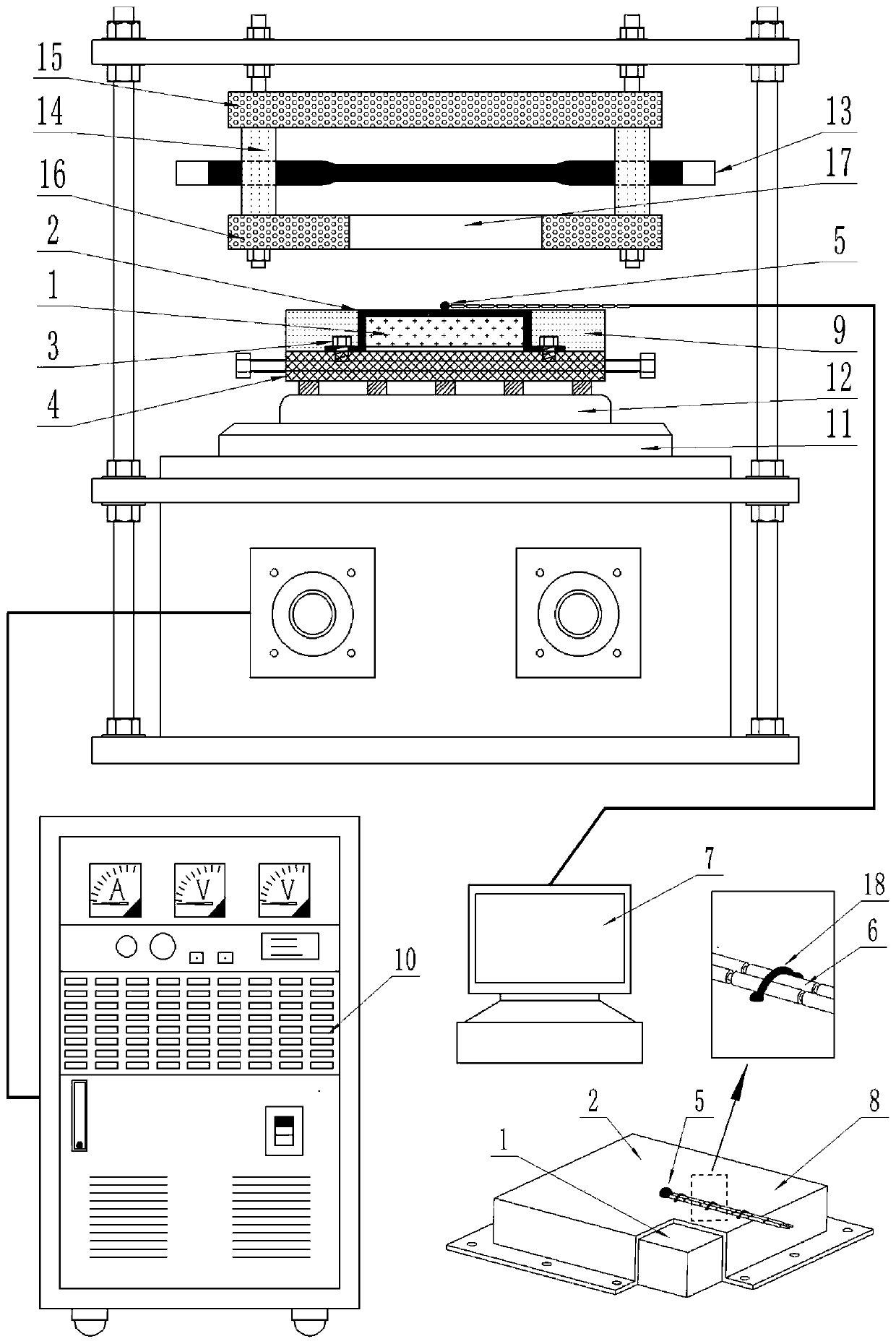

[0031] like figure 1 and figure 2 As shown, a heat / vibration test device for light-weight heat-resistant materials in an extremely high-temperature environment of 1700°C provided by the present invention includes: light-weight high-temperature-resistant heat-insulation material test piece 1, metal tungsten cover 2, high-temperature-resistant metal bolts 3, Heat insulation platform 4, double platinum rhodium temperature sensor 5, high temperature ceramic tube 6, industrial control computer 7, high temperature inorganic glue isolation coating 8, flexible ceramic fiber heat insulation blanket 9, vibration table drive controller 10, excitation table body 11, Vibration platform 12, silicon-molybdenum rod heating array 13, high-temperature ceramic frame 14, high-temperature ceramic insulation board A15, high-temperature ceramic insulation board B16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com