Coordinate calibration method, calibration system and mechanical arm

A technology of coordinate calibration and manipulators, which is applied in manipulators, program-controlled manipulators, image analysis, etc., can solve the problems of precision dependence, long processing cycle, cumbersome operation, etc., and achieve strong applicability and flexibility, good consistency, and calibration high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

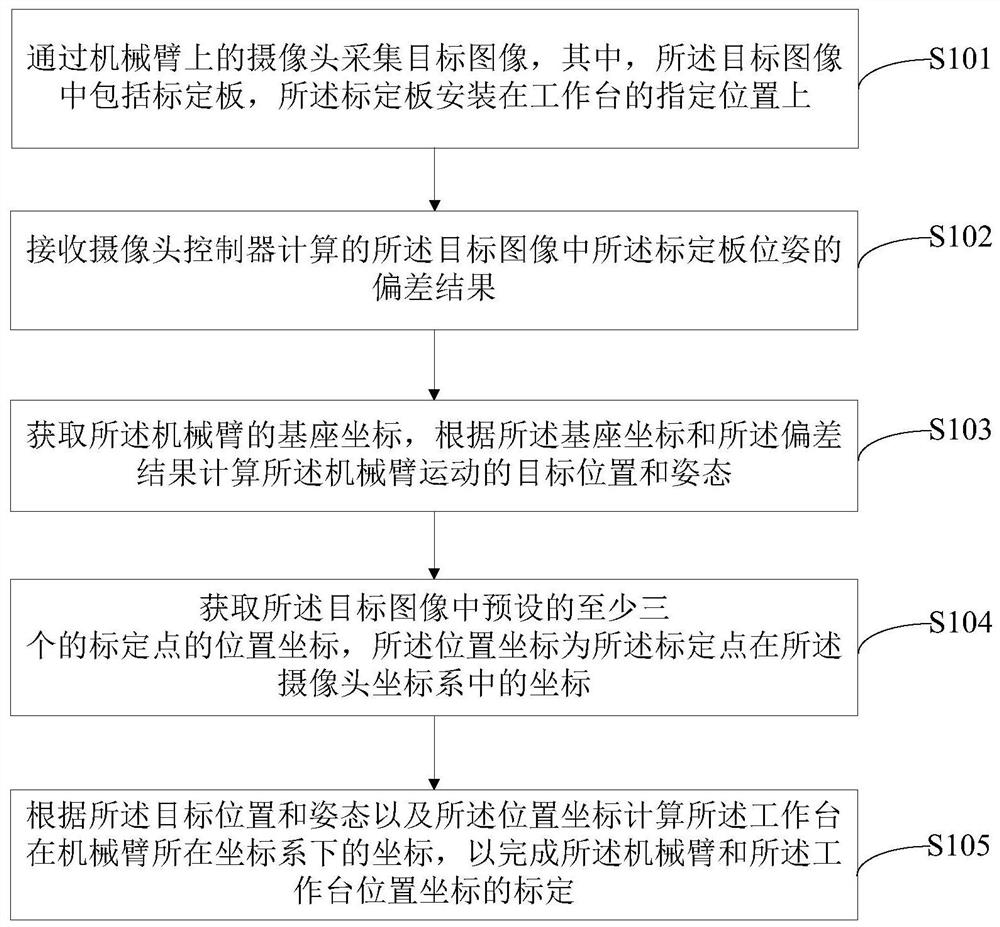

[0049] figure 1It is a schematic flowchart of a coordinate calibration method provided in Embodiment 1 of the present invention, and the method may include the following steps:

[0050] S101: Collect a target image through a camera on a robotic arm, wherein the target image includes a calibration plate, and the calibration plate is installed at a designated position on a workbench.

[0051] S102: Receive a deviation result of the calibration board pose in the target image calculated by the camera controller.

[0052] Optionally, before collecting the target image through the camera on the mechanical arm, it also includes:

[0053] Controlling the mechanical arm to move to a predetermined position, the predetermined position is set according to the position of the workbench.

[0054] Optionally, said collecting the target image through the camera on the mechanical arm includes:

[0055] controlling the mechanical arm to start moving from the predetermined position;

[0056]...

Embodiment 2

[0071] Image 6 The schematic diagram of the coordinate calibration system provided by Embodiment 2 of the present invention only shows the parts related to the embodiment of the present invention for the convenience of description.

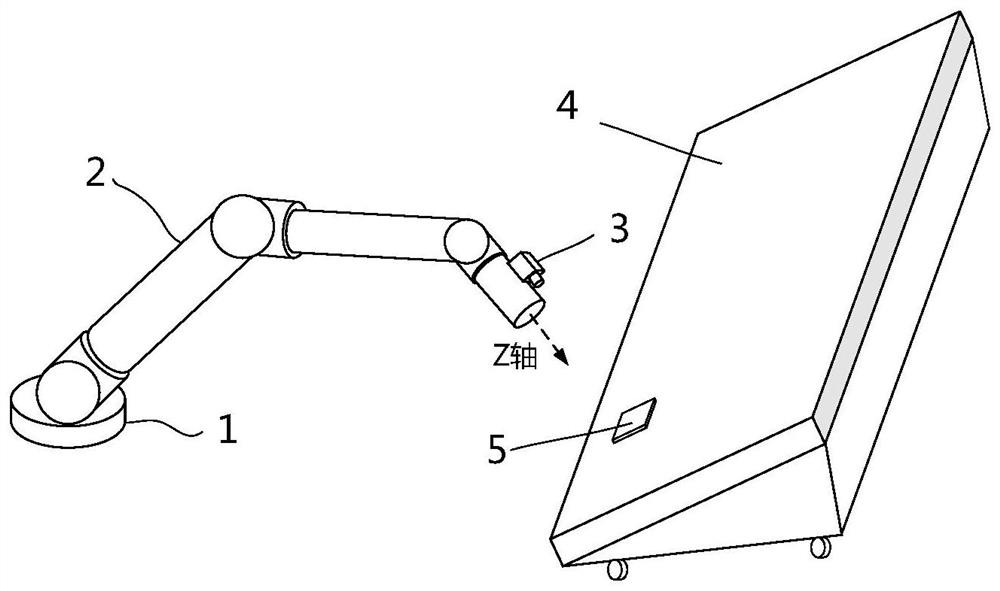

[0072] The coordinate calibration system includes an upper computer 61, a mechanical arm controller 62, a mechanical arm 63, a camera controller 64 and a camera 65, and the upper computer 61 is connected to the mechanical arm controller 62 and the camera controller 64 respectively. Connect for communication. The above-mentioned parts can be connected and communicated by means of Ethernet or the like.

[0073] The camera 65 is installed on the mechanical arm 63, the mechanical arm controller 62 is used to control the mechanical arm 63 to move; the camera controller 64 is used to control the camera 65 to collect the target image;

[0074] When the coordinate positioning system is in operation: the target image is collected by the camera 65 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com