A three-axis, seven-variable, full-degree-of-freedom positioning and tracking method for cameras in space

A camera, three-axis technology, applied to the camera in the field of three-axis, seven-variable, full-degree-of-freedom positioning and tracking in space, can solve the problems of difficult to eliminate pitch commutation hysteresis, imaging interference, lack of rotational degrees of freedom, etc. It is easy to promote and use, has good initialization effect, and has complete functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

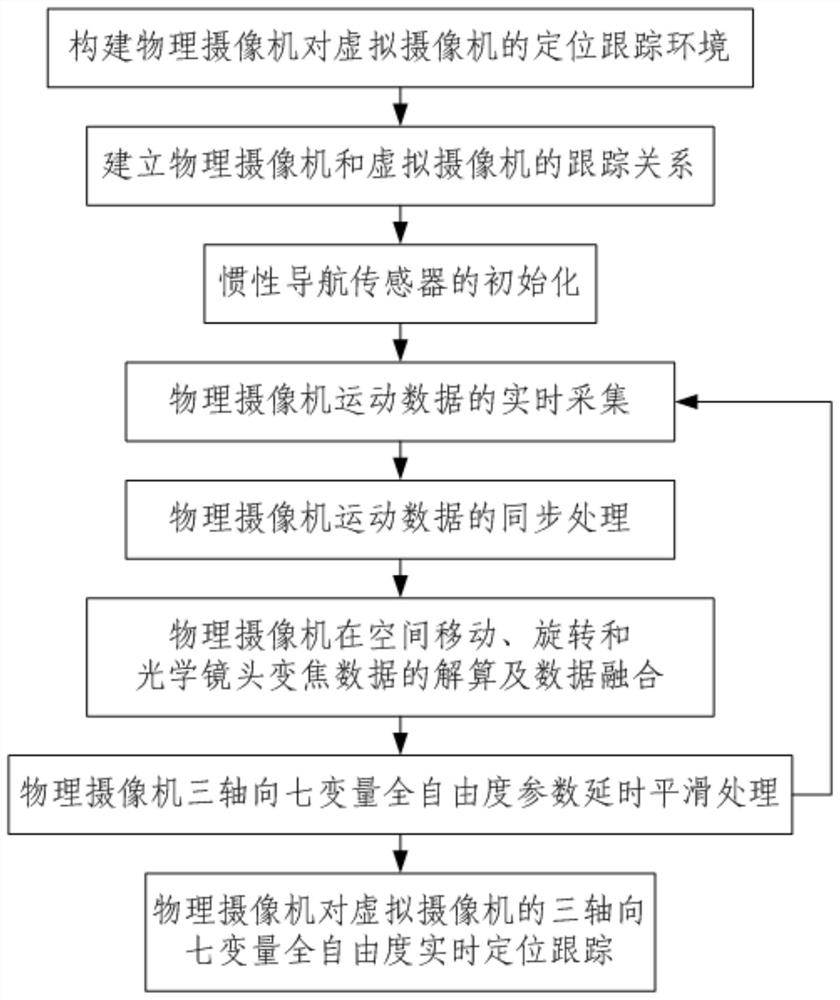

[0034] Such as figure 1 with figure 2 As shown, the camera of the present invention has a three-axis seven-variable full-degree-of-freedom positioning and tracking method in space, comprising the following steps:

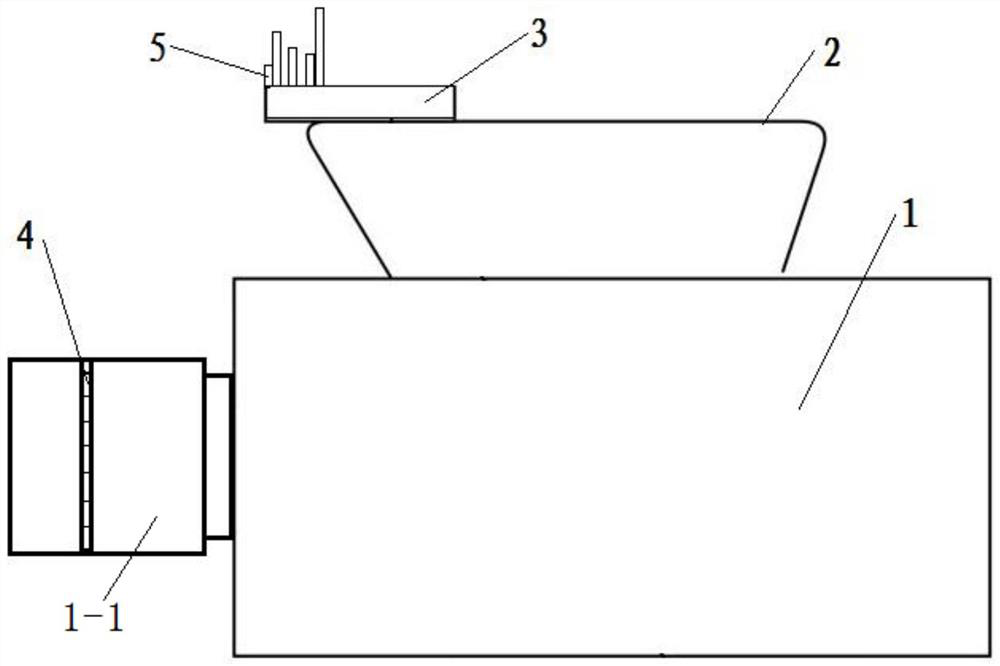

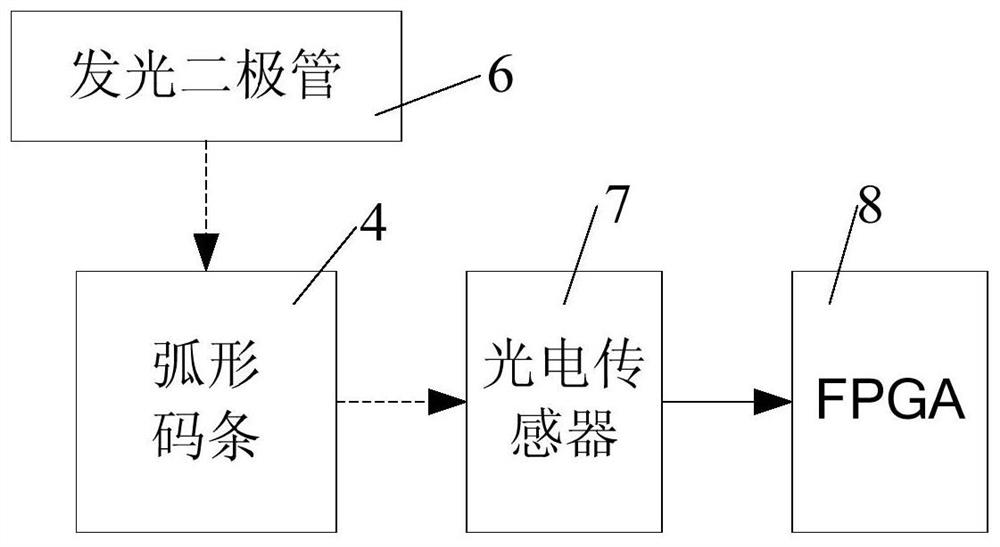

[0035] Step 1. Construct the positioning and tracking environment of the physical camera to the virtual camera: install a light source with a specified wavelength in the space, install a data processing box 3 on the physical camera 1, and the data processing box 3 includes a housing and a circuit fixed in the housing board, on which a plurality of optical sensors 5 with different heights are installed, for receiving the optical signal of the light source of the specified wavelength; the circuit board is integrated with a microprocessor and The connected inertial navigation sensor is installed on the lens 1-1 of the physical camera 1 for obtaining the zoom ring rotation angle data acquisition mechanism of the zoom ring rotation angle;

[0036] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com