Bridge-crossing multi-tangential-flow threshing device of combine harvester

A technology for combine harvesters and threshing devices, which is applied to harvesters, threshing equipment, cutters, etc., and can solve problems such as high labor intensity, difficult field use, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

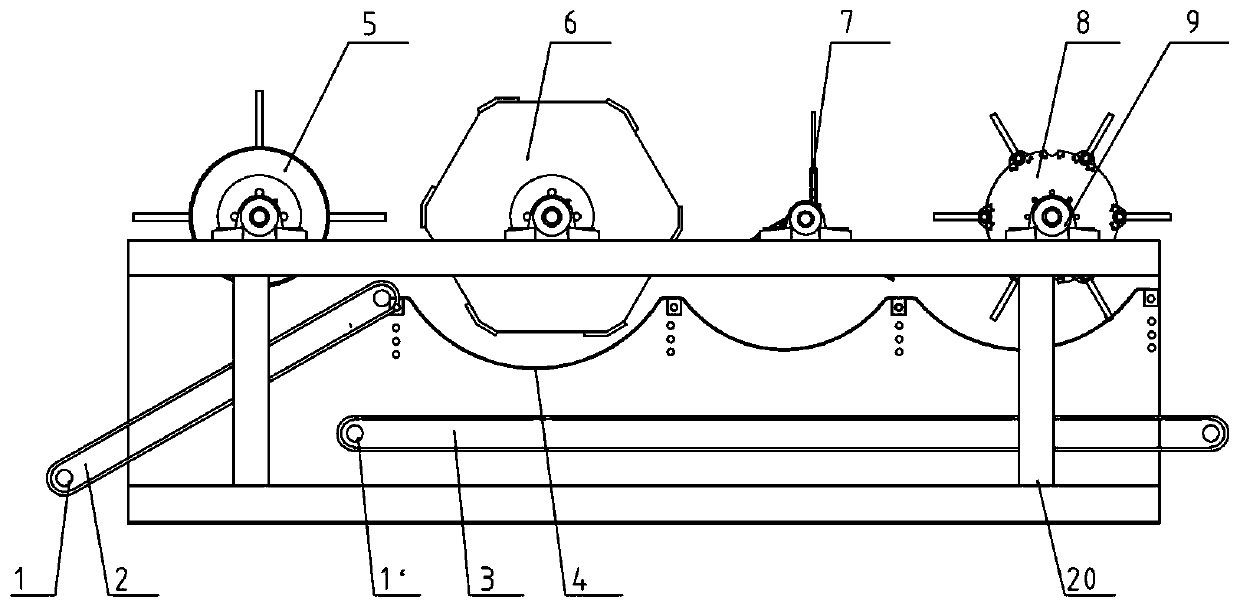

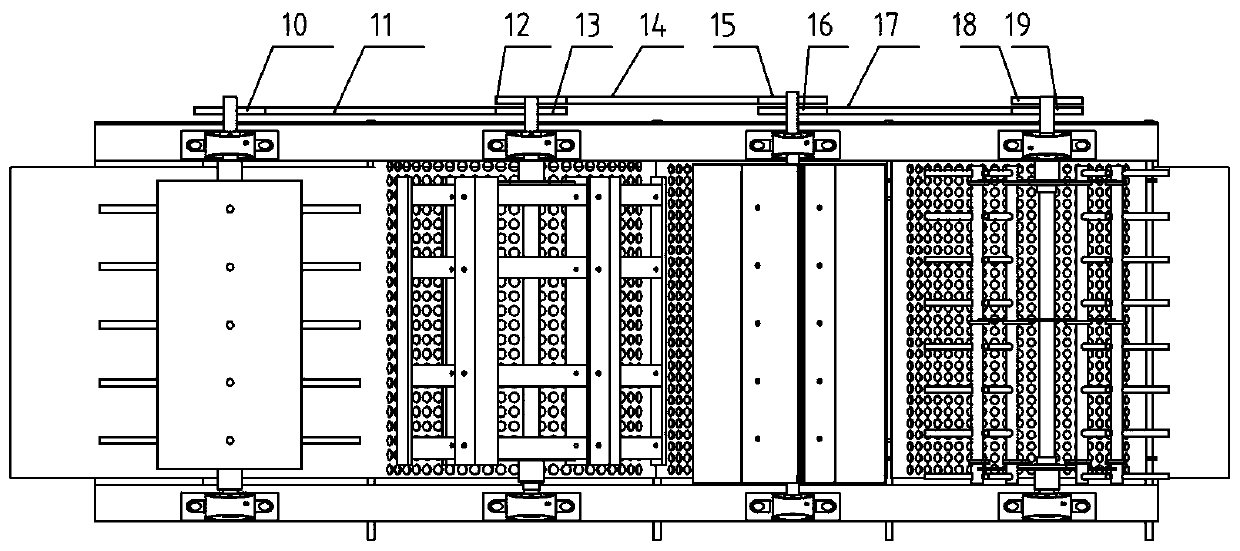

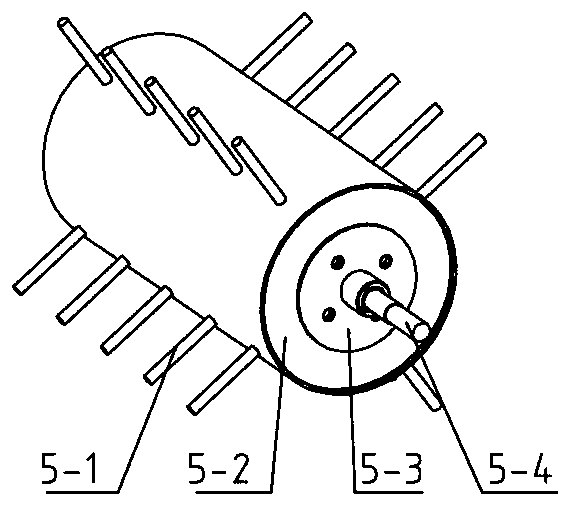

[0025] The basic structure of the combine harvester cross-bridge multi-cut flow threshing device of this embodiment is as follows: figure 1 As shown, the front end of the bridge support 20 of the frame structure is arranged with a plant feeding belt 2 from low to high, which is used to connect with the header, and the harvested crop plants are transported backward under the drive of the motor 1 . The output end of the plant feeding belt 2 is connected with the multi-concave sieve 4 formed by combining the first, second and third concavity sieves. The top of the plant feeding belt 2 supports and installs the plant feeding roller 5 through the bearing seat 9 on the bridge bracket 20 respectively, for assisting in conveying the crop plants. The tops of the first, second and third concave sieves are respectively equipped with a bar threshing cylinder 6, a plate type threshing cylinder 7, and a nail-tooth threshing cylinder 8, which are used to complete multiple threshing with diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com