Multi-angle spray system used for building environment

A sprinkler system and construction environment technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of waste of water resources, increase of labor intensity of workers, uneven spraying effect, etc. Good spraying effect, uniform spraying, and the effect of expanding the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

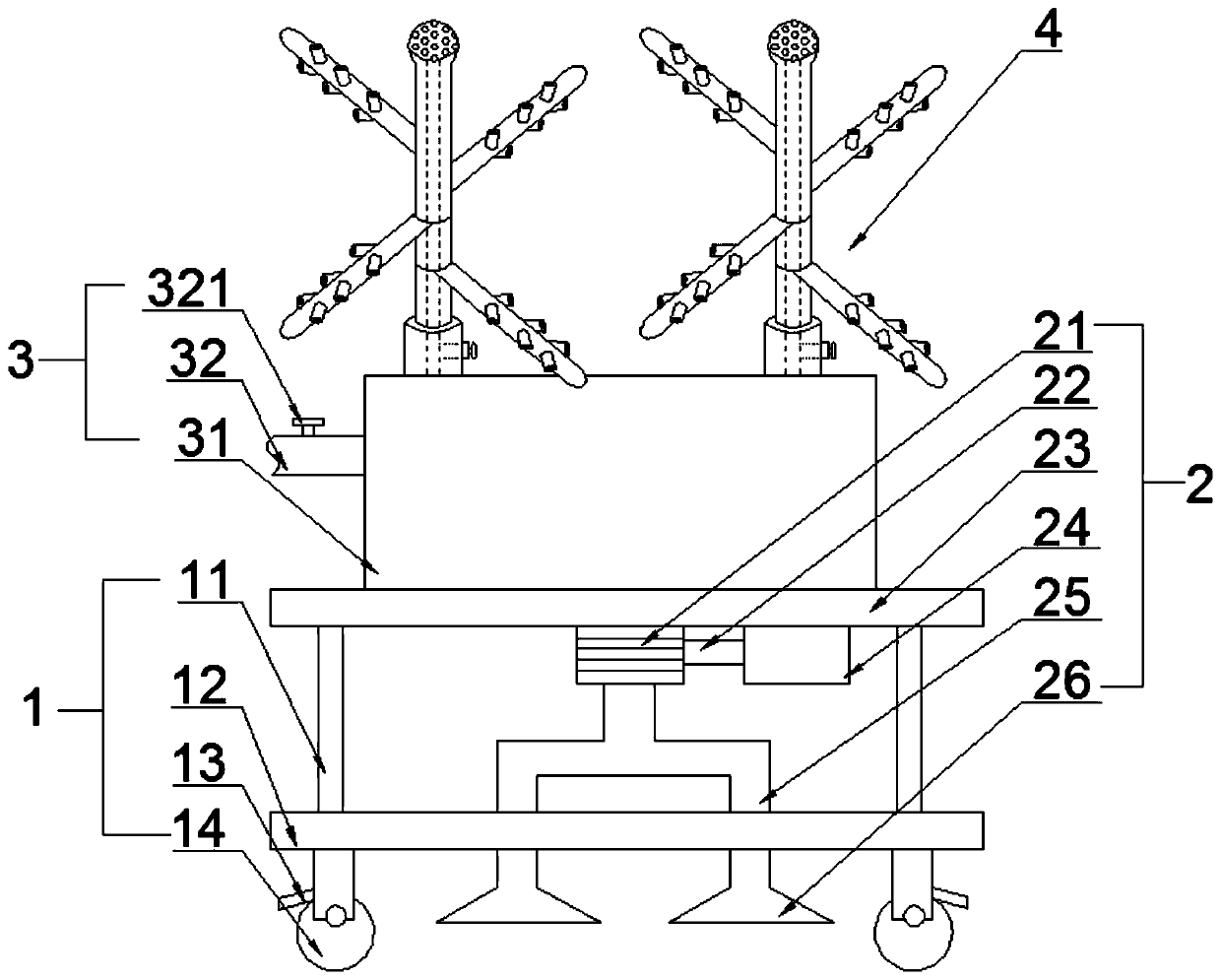

[0034] A multi-angle sprinkler system for building environments, including a mobile device 1, a dust collection device 2, a water storage device 3 and a spray device 4 that are sequentially connected and arranged from bottom to top;

[0035] Described dust collection device 2 comprises fixed plate 23, blower fan 21, dust collection box 24, suction pipe 25, air inlet pipe 22, dust collection cover 26, and described blower fan 21 is arranged on the lower surface of fixed plate 23, and described blower One side of the machine 21 is connected with a dust collection box 24 through an air extraction pipe 25, and the output end of the exhaust fan 21 is connected with a dust collection cover 26 through an air inlet pipe 22;

[0036] The water storage device 3 includes a water storage tank 31 and a water inlet pipe 32, and the water storage tank 31 is arranged above the fixing plate 23;

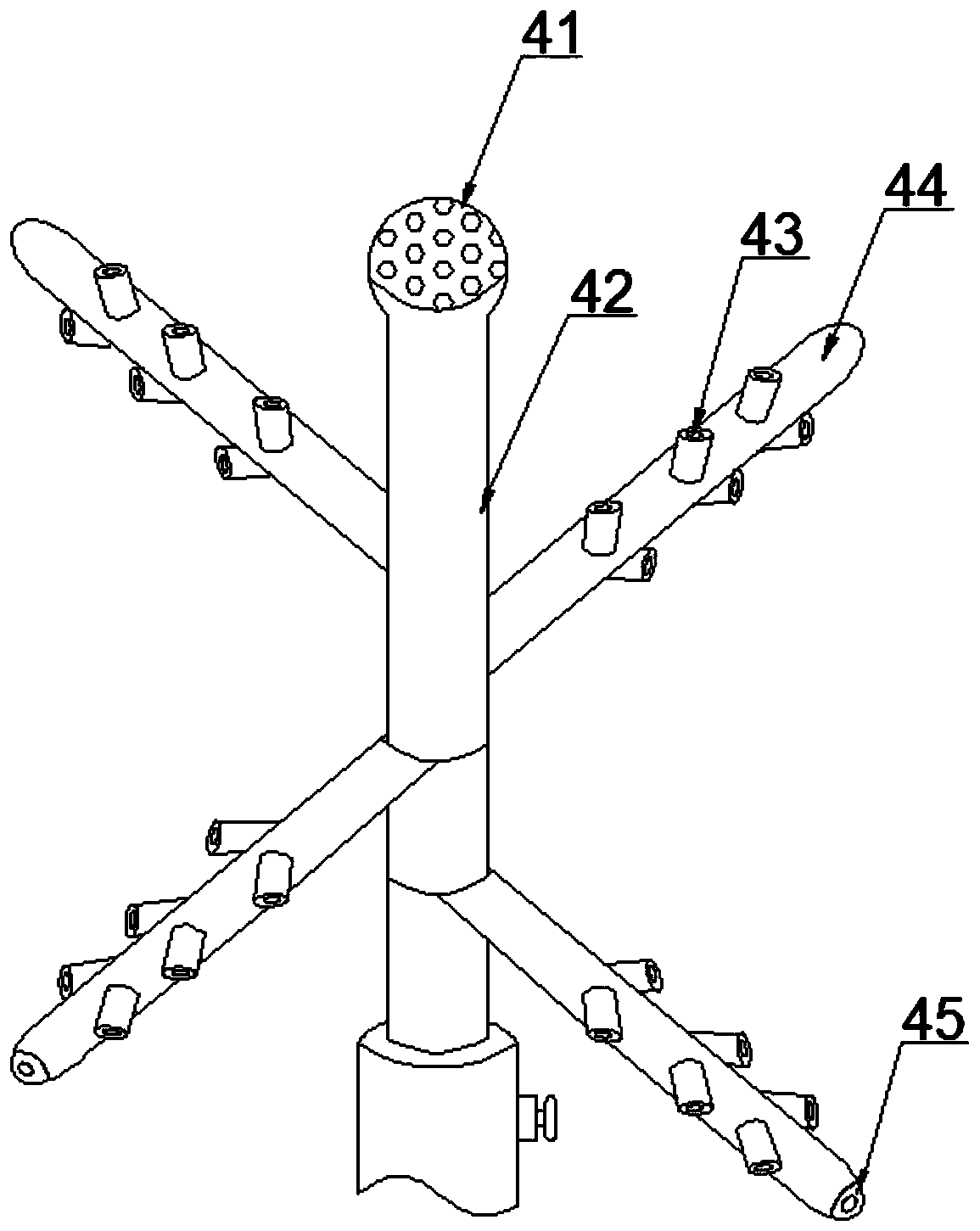

[0037] The spraying device 4 includes a main water pipe 42 and at least four water spray bars 44 f...

Embodiment 2

[0040] On the basis of Embodiment 1, the mobile device 1 includes a support plate 12, a support column 11 and a moving wheel 14, the air inlet pipe 22 runs through the support plate 12, and the support plate 12 and the fixed plate 23 Connected by the support column 11 , the moving wheel 14 is provided with a braking device 13 . The moving wheel 14 can move freely in the construction environment, thereby expanding the spraying area, and can control the reasonable position according to the needs, and freely control the movement and stop of the support plate 12 through the brake device 13, so as to ensure that the spraying system does not move randomly when necessary , it is more convenient to use, and the arrangement of the support plate 12 and the support column 11 makes the structure of the entire sprinkler system more stable.

Embodiment 3

[0042] On the basis of Embodiment 1, the top of the main water pipe 42 is provided with a sprinkler 41 . By being provided with watering nozzle 41 at the top of main water pipeline 42, when making to spray building environment, expanded spraying area, can better cover the flying dust in high altitude, thereby can better control the high altitude. Dust management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com