Glass crusher

A glass breaking and crusher technology, which is applied in the field of mechanical devices, can solve the problems of glass debris splashing, damage to human physical and mental health, and insecurity, and achieve the effects of avoiding splashing, improving safety performance, and promoting crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

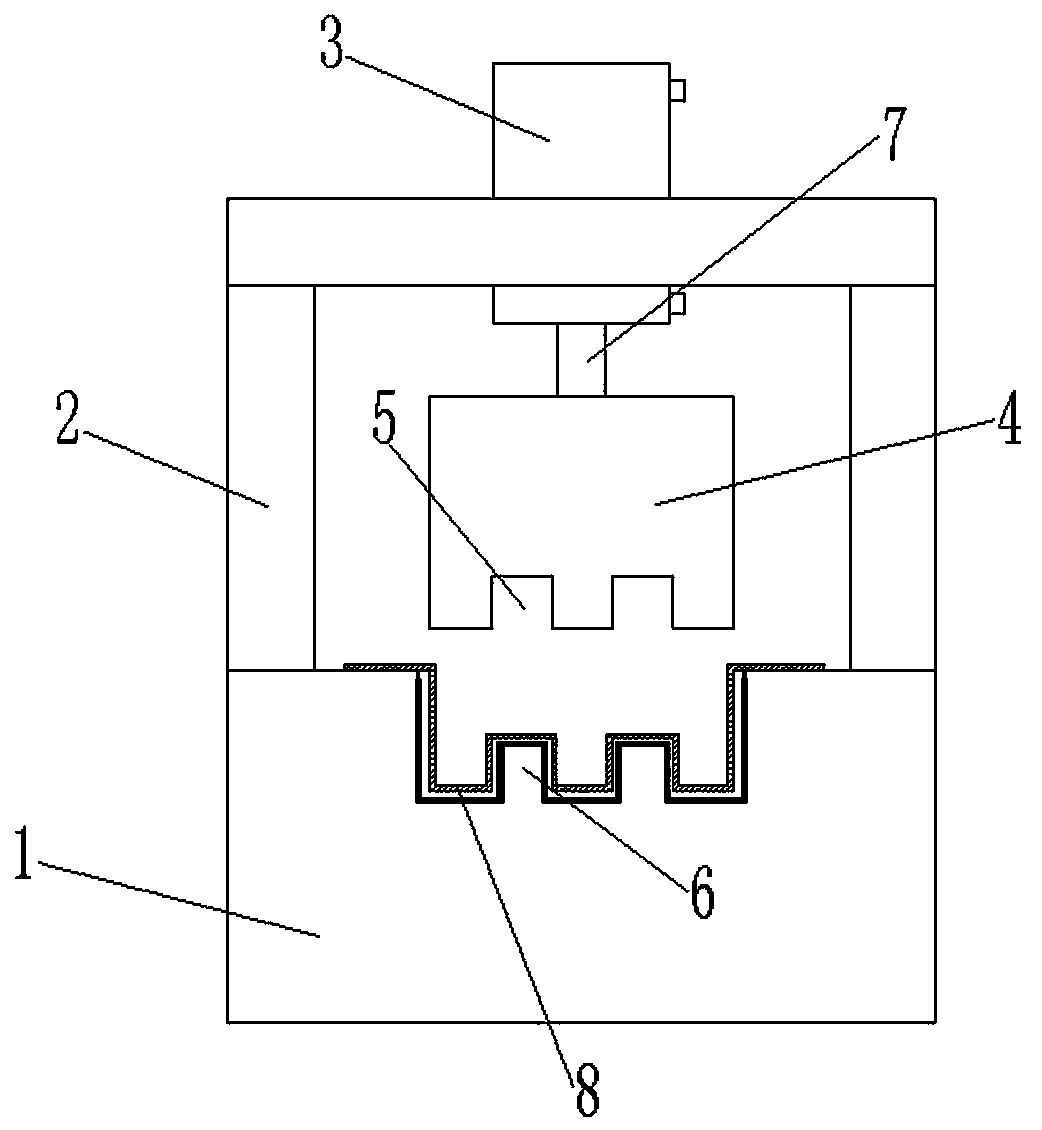

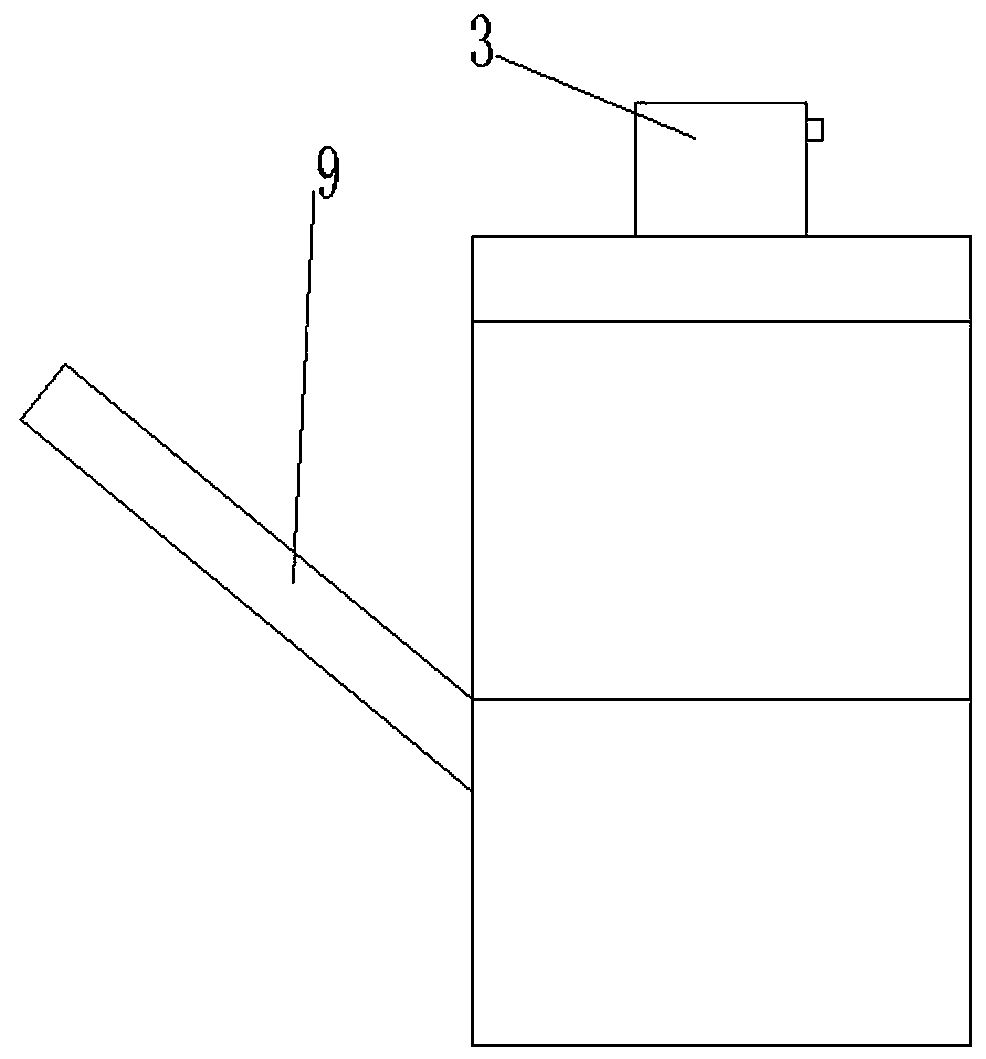

[0010] figure 1 , 2 Middle: machine base 1, frame 2, oil cylinder 3, upper mold 4, groove 5, convex body 6, moving plunger 7, iron plate 8, feeding slide plate 9.

[0011] A glass breaker, comprising a base 1, a frame 2 welded to the base 1, the glass breaker also includes an oil cylinder 3, an upper die 4, and the upper die 4 is provided with a serrated groove 5 , specifically, the groove 5 is in the shape of a rectangular tooth. The base 1 is provided with a convex body 6, the groove 5 and the convex body 6 are engaged up and down, and a large batch of large glass is put between the groove 5 and the convex body 6, and the moving plunger of the oil cylinder 3 The up and down telescopic movement drives the upper mold 4 to perform the up and down extrusion stroke movement, and exerts pressure and bending external force on the glass during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com