Concrete mixer frame

A technology of concrete mixer truck and frame, which is applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems of high height of the mixer truck, unbalanced center of gravity of the whole vehicle, hidden dangers of vehicle safety, etc. cost, improve overall strength, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

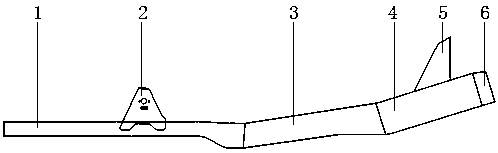

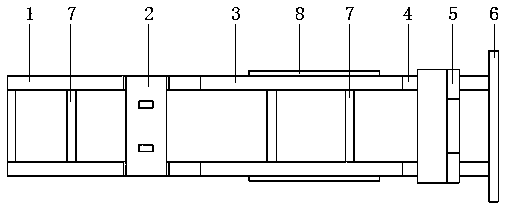

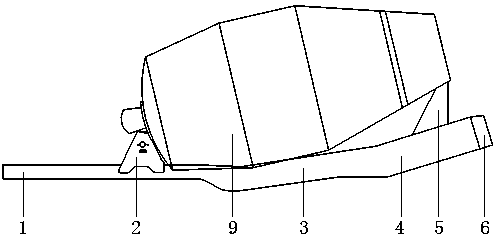

[0023] refer to Figure 1 ~ Figure 3 , the present invention is achieved in this way: a concrete mixer truck frame, which includes two chassis longitudinal beams arranged in parallel at intervals, and the two chassis longitudinal beams are fixedly connected through a number of crossbeams 7, and each chassis longitudinal beam adopts an integral It is shaped and includes the first beam section 1, the second beam section 3, the third beam section 4 and the tail beam section 6 arranged in sequence from front to rear; the top of the first beam section 1 of the two chassis longitudinal beams is installed with a front The support seat 2, the rear support seat 5 is installed on the top of the third beam section 4 of the two chassis longitudinal beams, and the outer sides of the second beam section 3 of the two chassis longitudinal beams are respectively provided with reinforcing ribs 8 .

[0024] refer to Figure 1 ~ Figure 3 As shown, in the present invention, the tail ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com