An anti-drop conveyor

A conveyor, anti-dropping technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as machine failure, falling, item damage, etc., to achieve smooth transportation and reduce scrap rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0026] As an embodiment, the present invention provides an anti-drop conveyor, comprising:

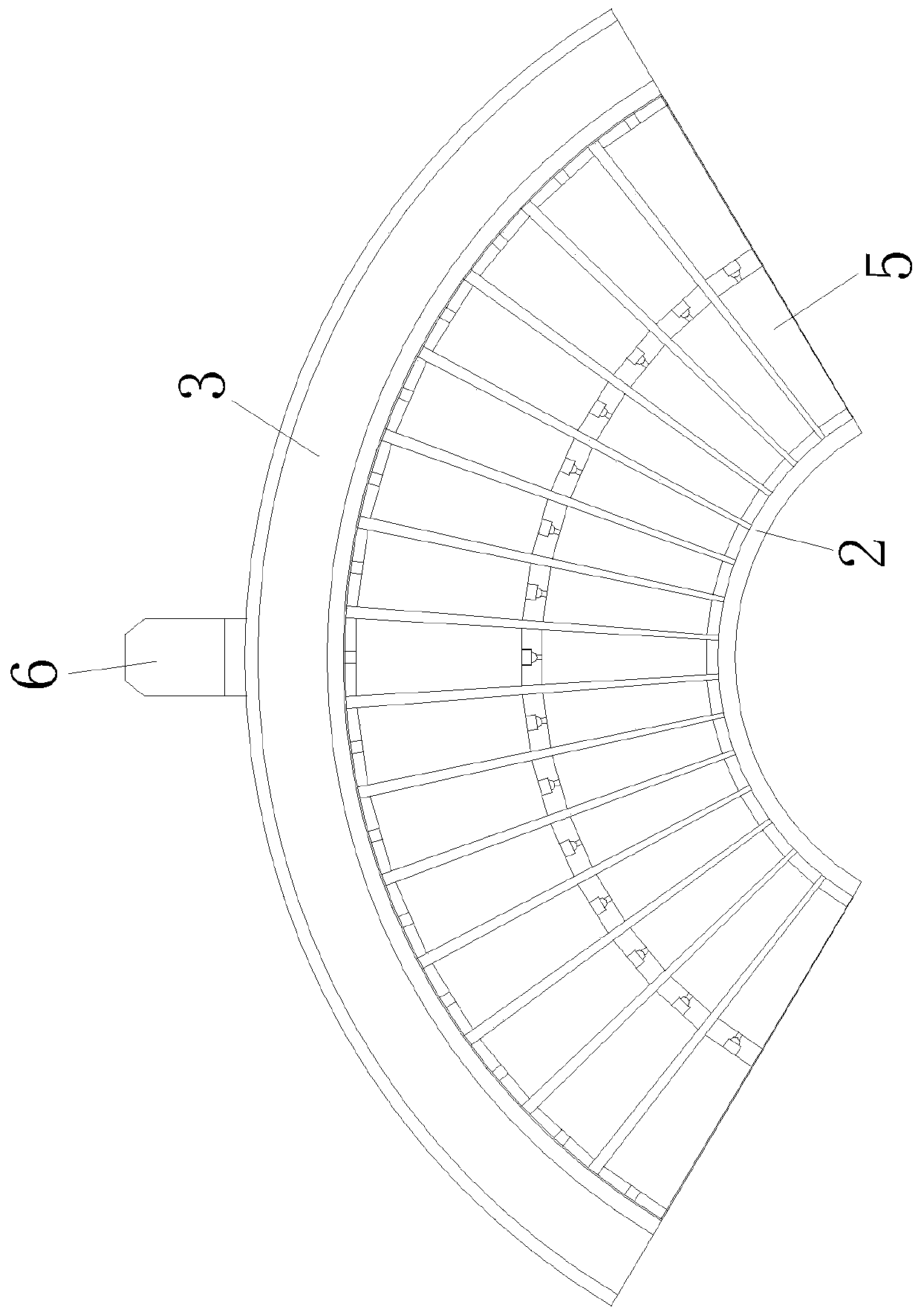

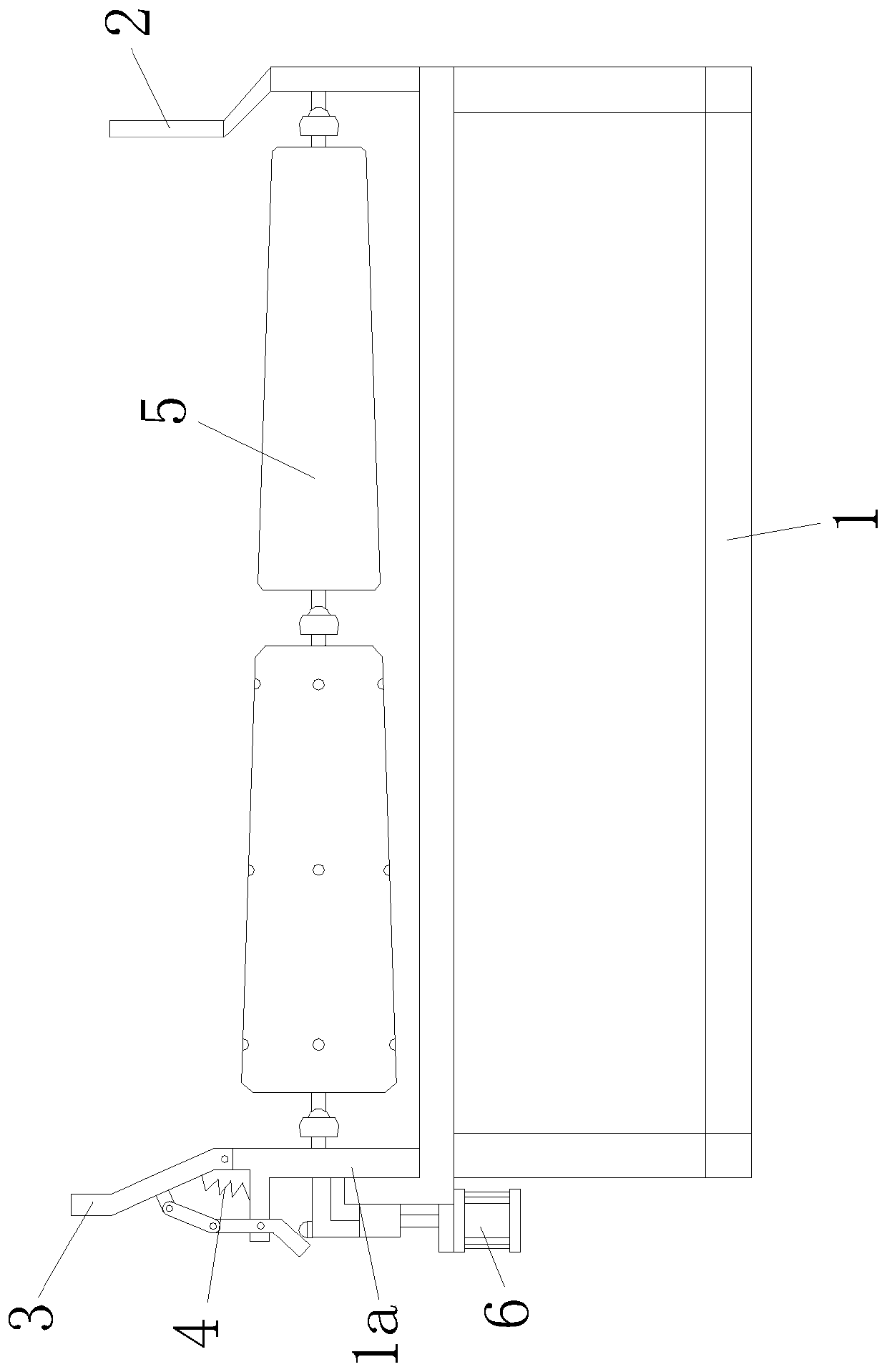

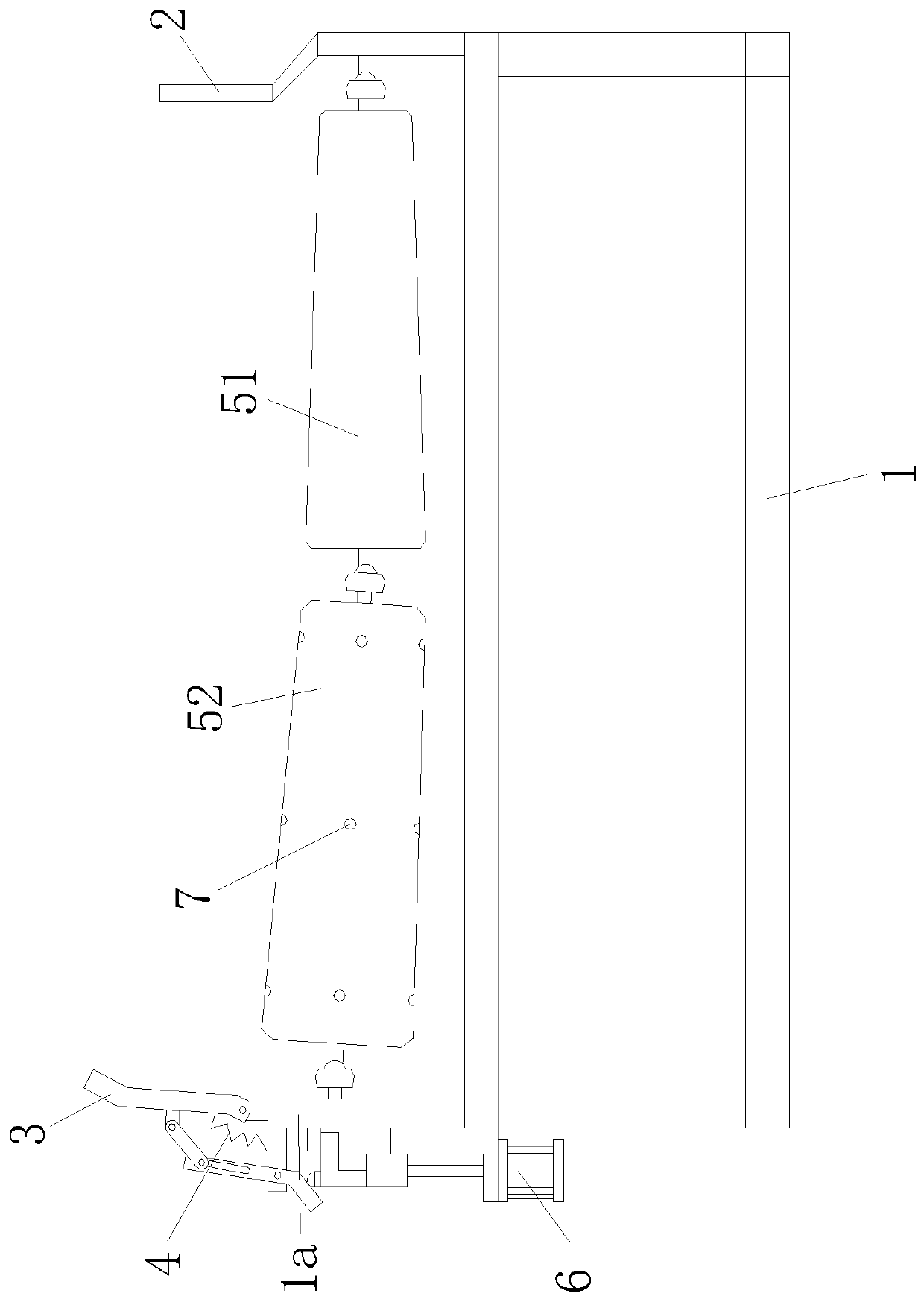

[0027] The frame has an arc-shaped conveying channel, and a mounting block that can slide vertically is provided on the outside near the conveying channel, and an initial end surface for supporting the mounting block is provided;

[0028] Inner edge protection, set the rack close to the inner side of the conveying channel;

[0029] The outer edge guard is rotatably arranged at the end of the mounting block;

[0030] One end of the elastic piece is connected with the outer edge, and the other end is connected with the installation block, so that the outer edge remains vertical;

[0031] The roller assembly is arranged in the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com