Drilling fluid forced-cooling device and low-temperature circulatory drilling method

A drilling fluid circulation and forced cooling technology, used in household refrigeration devices, cooling fluid circulation devices, wellbore/well components, etc., can solve problems such as the inability to work life of downhole tools, and achieve the effect of reducing circulating temperature and improving working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

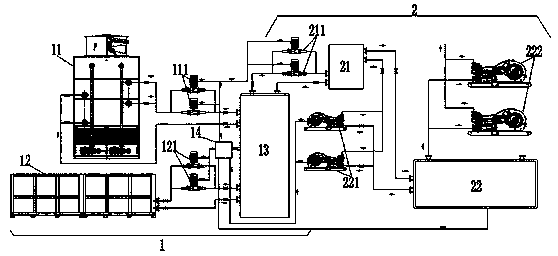

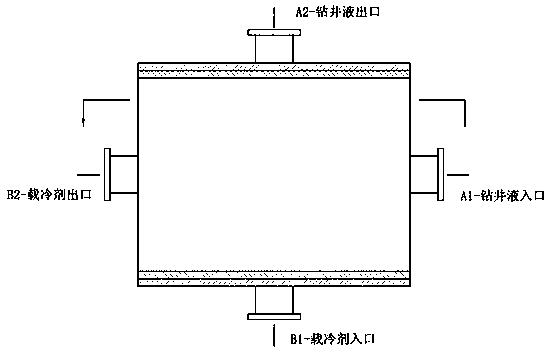

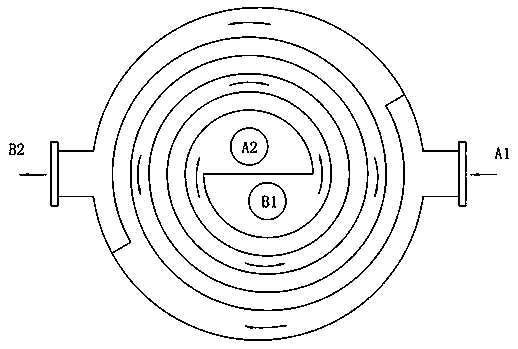

[0031] see figure 1 figure 2 ,and image 3 As shown, a drilling fluid forced cooling device is composed of a brine cooling system 1 and a convective heat exchange system 2, and the brine cooling system 1 and the convective heat exchange system 2 are connected in series in the device;

[0032] The brine cooling system 1 includes a cooling tower 11, a water chiller 12, a brine tank 13, a control feedback unit 14, a cooling water circulation pump 111 and a chilled water circulation pump 121. The cooling tower 11 is connected with the brine through the cooling water circulation pump 111 The tanks 13 are connected, the chiller unit 12 is connected with the brine tank 13 through the chilled water circulation pump 121, and the control feedback unit 14 is arranged on the brine tank 13;

[0033] The convective heat exchange system 2 includes a heat exchanger 21, a drilling fluid tank 22, a brine circulation pump 211, a drilling fluid circulation pump 221 and a drilling pump 222, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com