Debris flow formation tunnel excavation construction method and structure

A technology of tunnel excavation and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as inability to effectively release the potential energy of debris, collapse of rock mass on the face, and support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The applicant makes a unified explanation of the following technical terms. In this embodiment, the tunnel main tunnel is the main body of the main tunnel to be constructed, which can be divided into upper steps, middle steps and lower steps during the construction process, and the upper step is the tunnel main tunnel. The upper section of the tunnel, the middle step is the middle section of the main tunnel, and the lower step is the lower section of the tunnel; the face is the working face that continuously advances during the construction of the tunnel; there is debris fluid in the debris flow formation Debris Fluid is contained in the Debris Fluid Chamber.

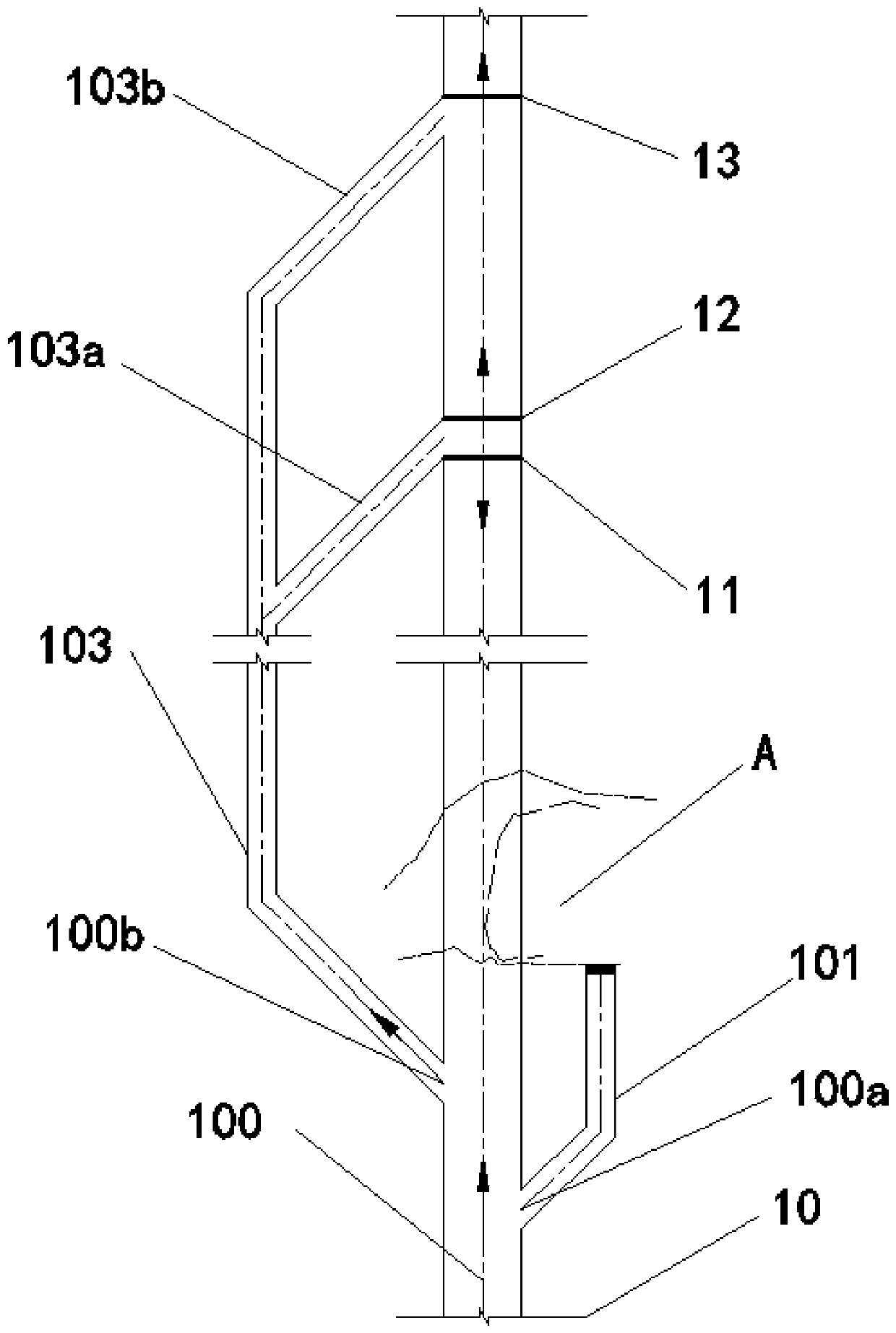

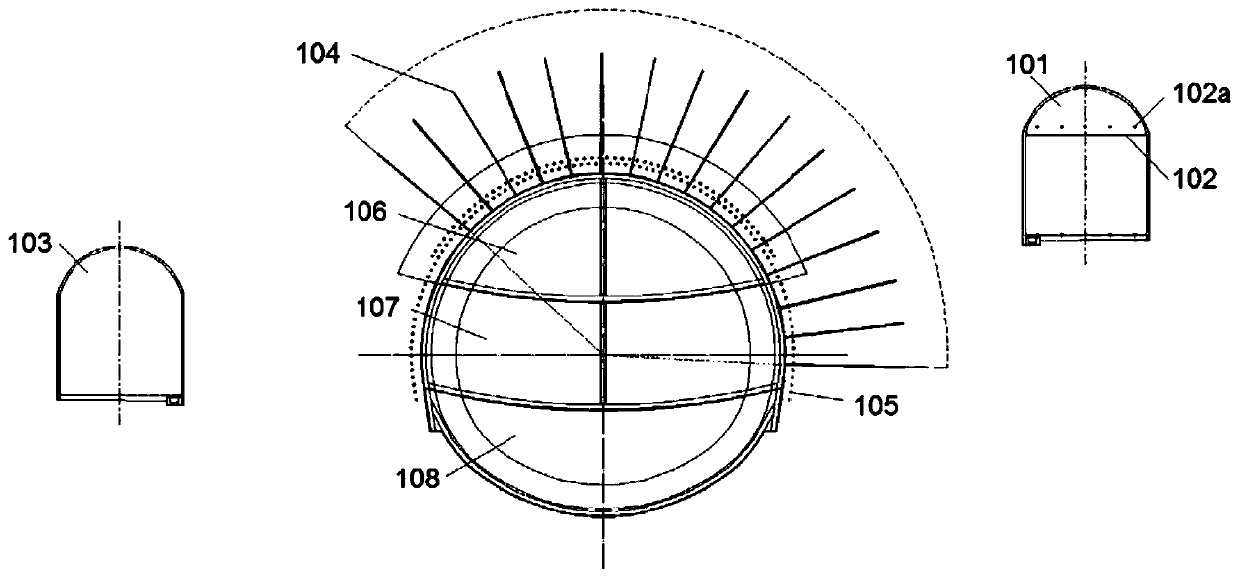

[0026] Please also see figure 1 and figure 2 , which is the excavation construction structure diagram and construction cross-section diagram of the debris flow formation tunnel of the present invention. The invention provides a method for excavating a tunnel in a debris flow formation, which mainly includes S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com