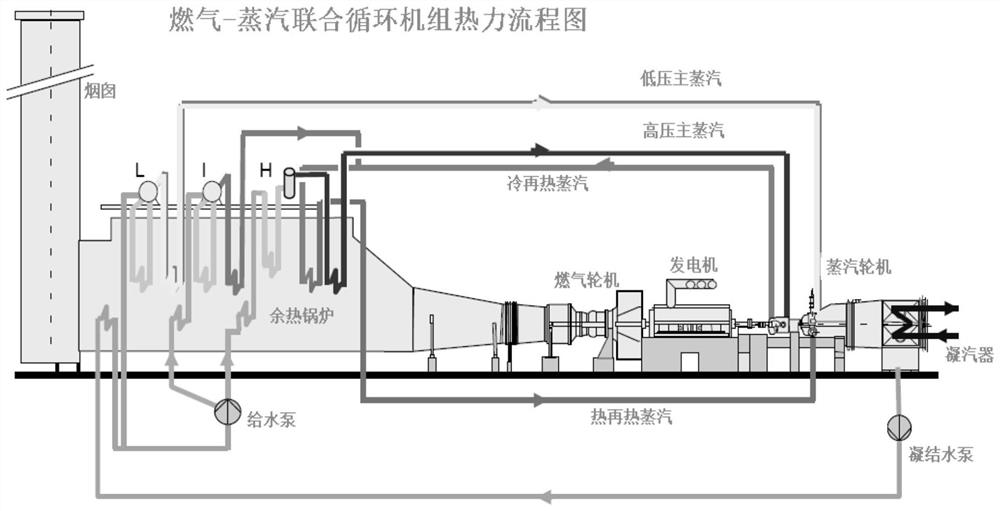

A Siemens 9f gas turbine combined cycle unit constant exhaust cylinder temperature clutch engagement control method

A combined cycle unit, Siemens' technology, applied in the field of meshing control, can solve the problems of low support rigidity of the No. 8 bearing, affecting the safety and stability of the unit, unstable vibration of the bearing bush, etc., and achieves a simple and easy operation method, ensuring safety and stability performance, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

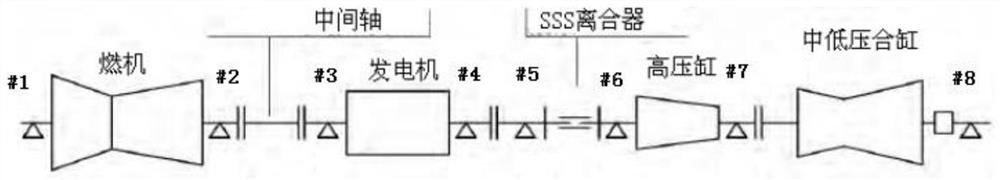

[0025] By analyzing the start-up process of Siemens 9F gas turbine combined cycle unit, the present invention finds out the root cause of relatively large unit vibration in the engagement process of the steam turbine and SSS clutch, and proposes a clutch engagement control method with constant exhaust cylinder temperature to solve the vibration problem .

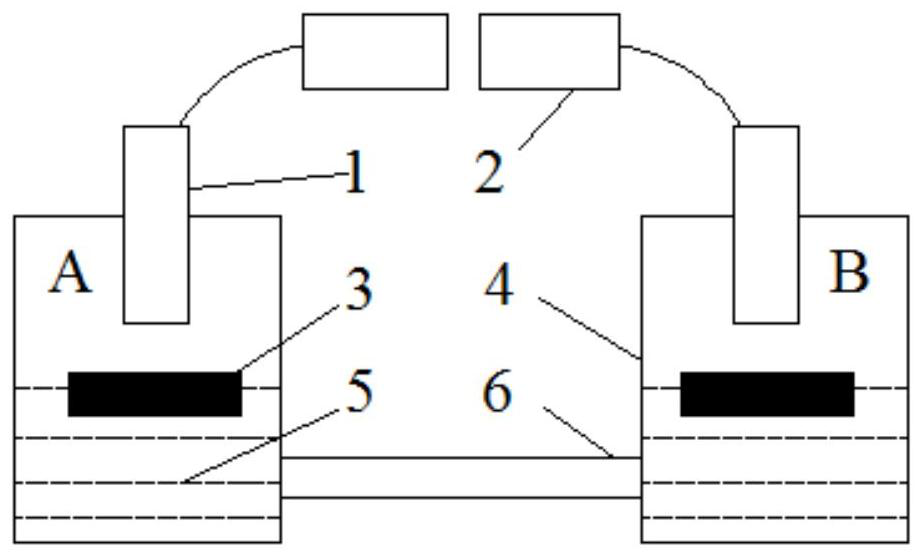

[0026] As mentioned above, the SSS clutch is used between the unit generator and the steam turbine to engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com