Automatic constant-temperature high-definition dyeing device

A dyeing device and constant temperature technology, applied in the field of biochemical dyeing, can solve problems such as low efficiency and troublesome operation, and achieve the effects of avoiding cross-contamination, convenient removal and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

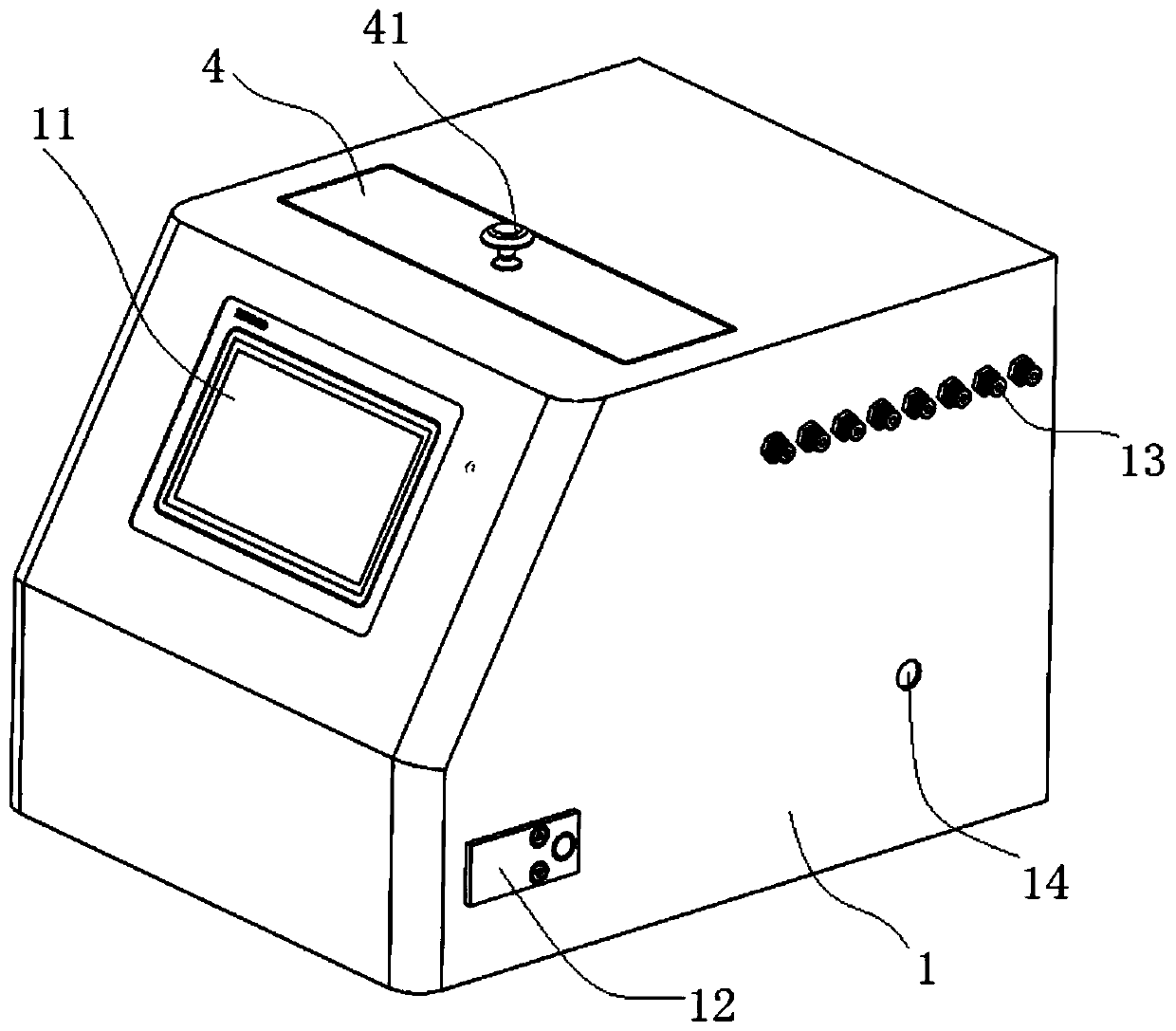

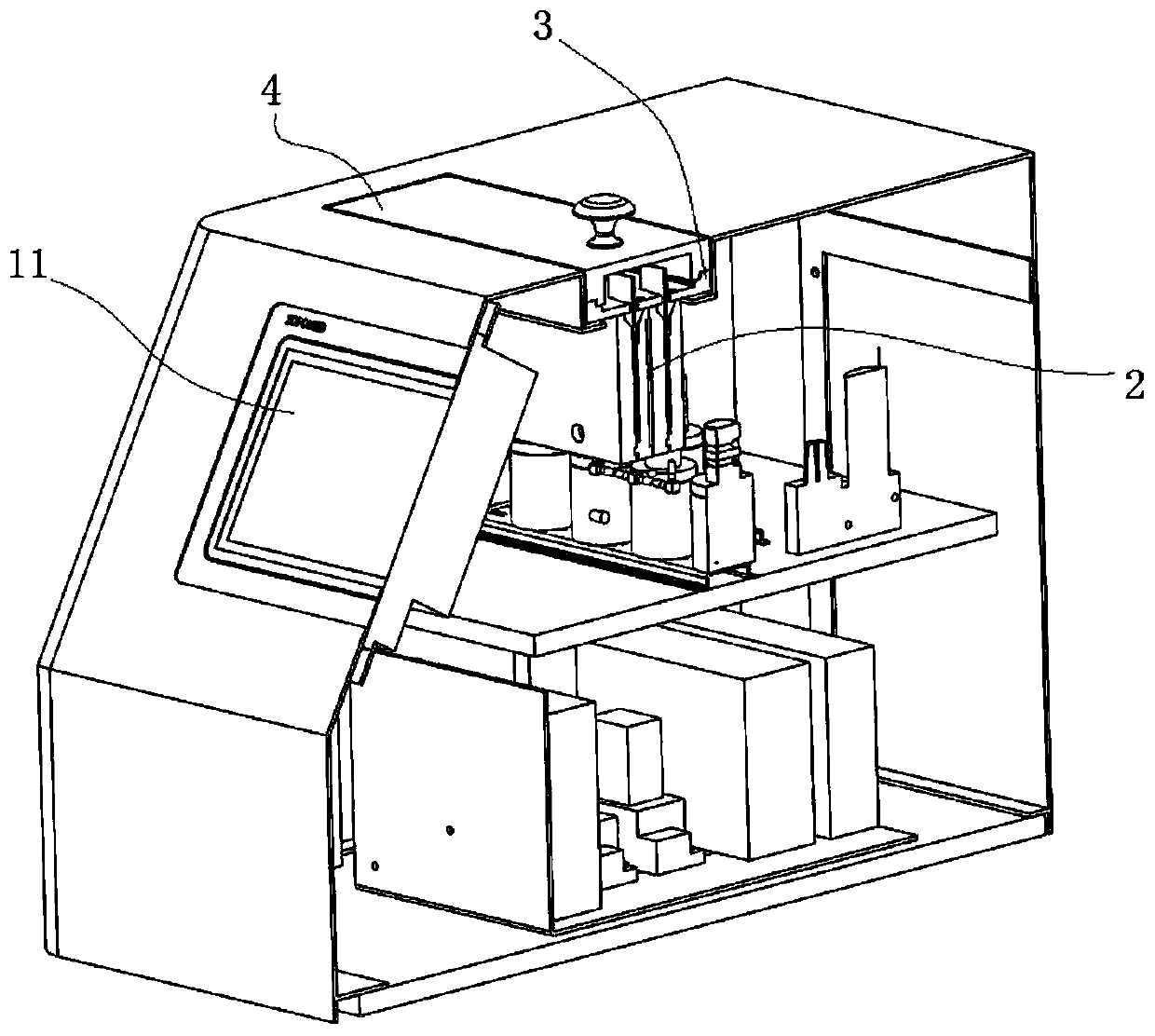

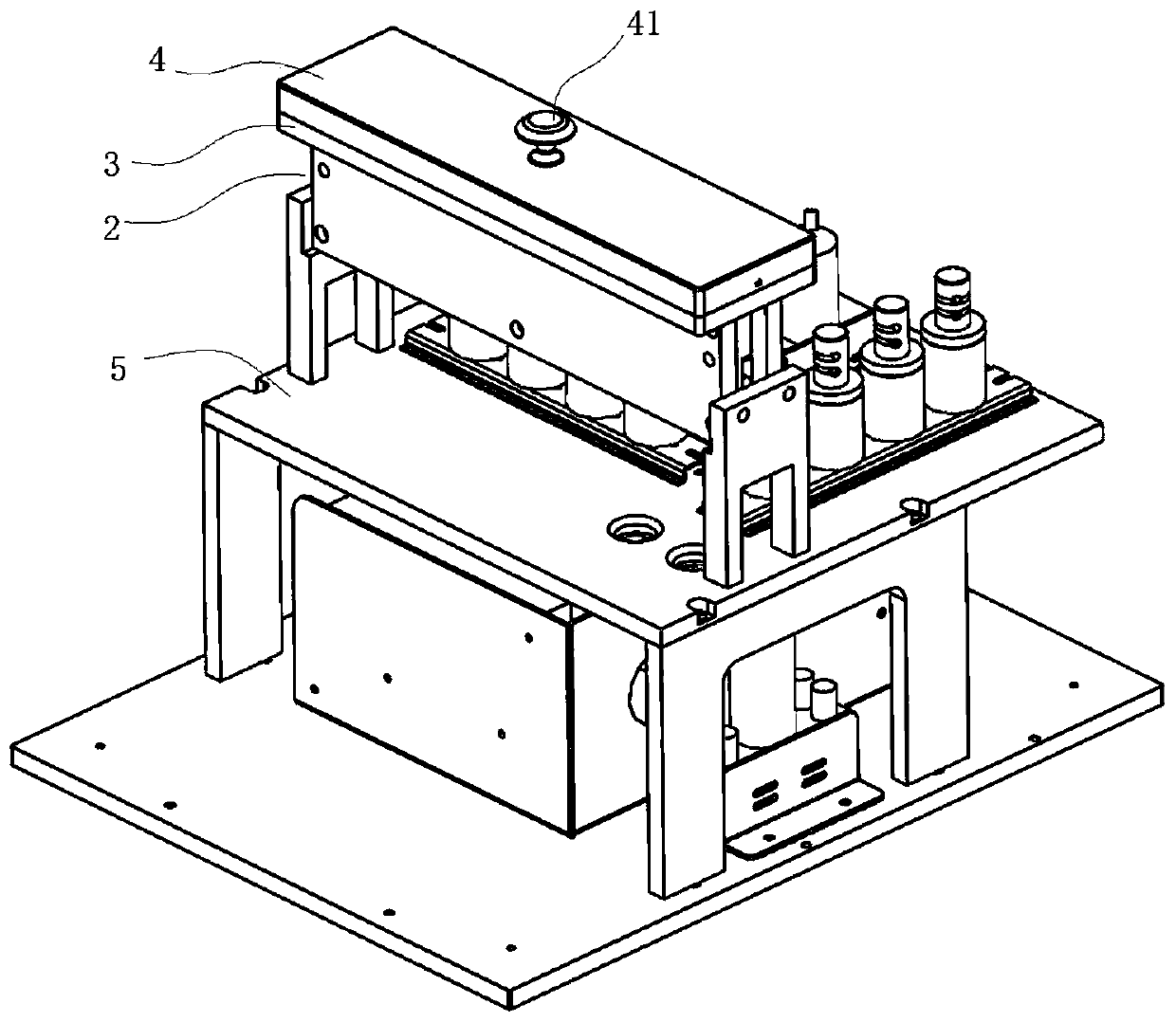

[0045] like Figure 1-Figure 13 As shown, the automatic constant temperature high-definition dyeing device includes a housing 1 and a drip dyeing assembly. The drip dyeing assembly includes several dyeing chamber units 22, and there are 12 dyeing chamber units in this embodiment. The staining chamber unit 22 is provided with a staining chamber 221 with an upper opening for placing the staining solution and for inserting the glass slide 6 loaded with the sample. The distance between the front and rear side walls of the staining cavity 221 is greater than the thickness of the glass slide 6, preferably greater than 0.5 mm, such as 0.5-1 mm.

[0046] Figure 10As shown, the left and right side walls of the staining chamber 221 are provided with slide guide grooves 2212 extending up and down. There are gaps in between. The width of the slide guide groove 2212 is preferably slightly larger than the thickness of the slide, preferably 1.2-1.5mm. The width of the slide guide groove...

Embodiment 2

[0105] The difference between this embodiment and Embodiment 1 is that in this embodiment, the liquid discharge hole and the liquid inlet hole are set independently, and no longer share one hole. The liquid discharge hole 228 is arranged at the position of the liquid inlet and outlet hole in Embodiment 1, the liquid inlet hole 227 is arranged on the side wall of the dyeing structural unit, and the liquid inlet hole is connected with the dyeing cavity of the corresponding dyeing chamber unit.

[0106] The liquid inlet hole 227 is used to connect with the liquid inlet pipeline, and the liquid inlet pipeline includes a reaction solution parallel pipeline, and the reaction solution parallel pipeline includes several reaction solution pipelines for providing different types of dyeing reaction solutions in parallel, such as respectively Reaction solution pipeline A, reaction solution pipeline B, reaction solution pipeline C, reaction solution pipeline D, reaction solution pipeline E ...

Embodiment 3

[0110] The difference between this embodiment and Embodiment 1 is that 4 rows of dyeing bin units are set in this embodiment, and 6 dyeing bin units are arranged in each row, that is, there are 24 dyeing bin units in total, and 24 dyeing bin units can be realized at a time. Staining of slides.

[0111] The four dyeing structural units are provided with two controllable constant temperature heating modules, and the two dyeing structural units share one controllable constant temperature heating module for heating.

[0112] Of course, each dyeing structural unit can also be provided with an independent controllable constant temperature heating module.

[0113] In other embodiments, 6 rows of dyeing chamber units can also be set, with a total of 36 dyeing chamber units, which can dye 36 slides at a time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com