Preprocessing pretreatment device for raw materials of flour

A pre-processing and raw material technology, applied in the field of flour raw material pre-processing and pre-processing equipment, can solve the problems that plague flour processing enterprises, and achieve the effect of compact structure, reasonable design, novel and unique ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings.

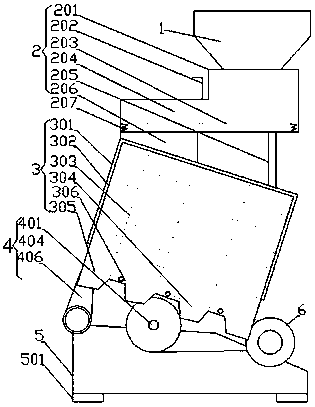

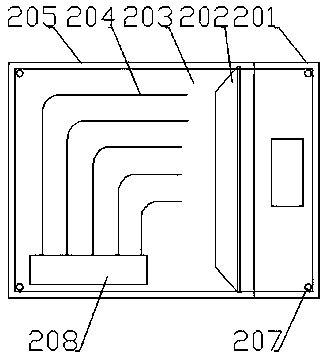

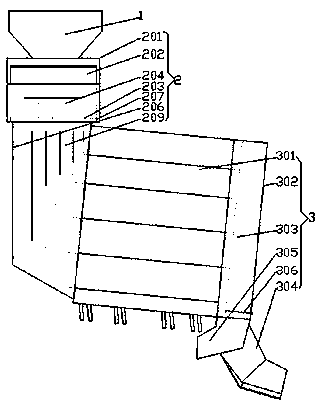

[0023] like Figure 1-5 As shown in , a pre-processing device for flour raw material preprocessing includes a feeding hopper 1, the feeding hopper 1 is connected to the material opening of the screed box 2, and the material guide shell 206 on the lower side of the screed box 2 is connected to the screening box 3 through On the rear side, the lower part of the screening box 3 is connected obliquely to the swing mechanism 4. The wheel disc 407 of the swing mechanism 4 is connected to the motor 6 through a belt. The motor 6 and the swing mechanism 4 are installed on the frame 5, and the bottom of the frame 5 is provided with an anti-vibration pad. 501; the screed box shell 201 of the screed box 2 is movable and vertically provided with a shutter 202, and the screed box shell 201 is horizontally supported and connected to the screed plate 203 by the spring 207, and the end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap