Automobile chassis punching die

A technology for stamping dies and automobile chassis, which is applied in the field of stamping dies, can solve problems such as low operation efficiency, difficulty in adjusting the level and height of the die, and achieve the effects of convenient inspection and maintenance, overcoming the complexity of mechanical parts, and excellent applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

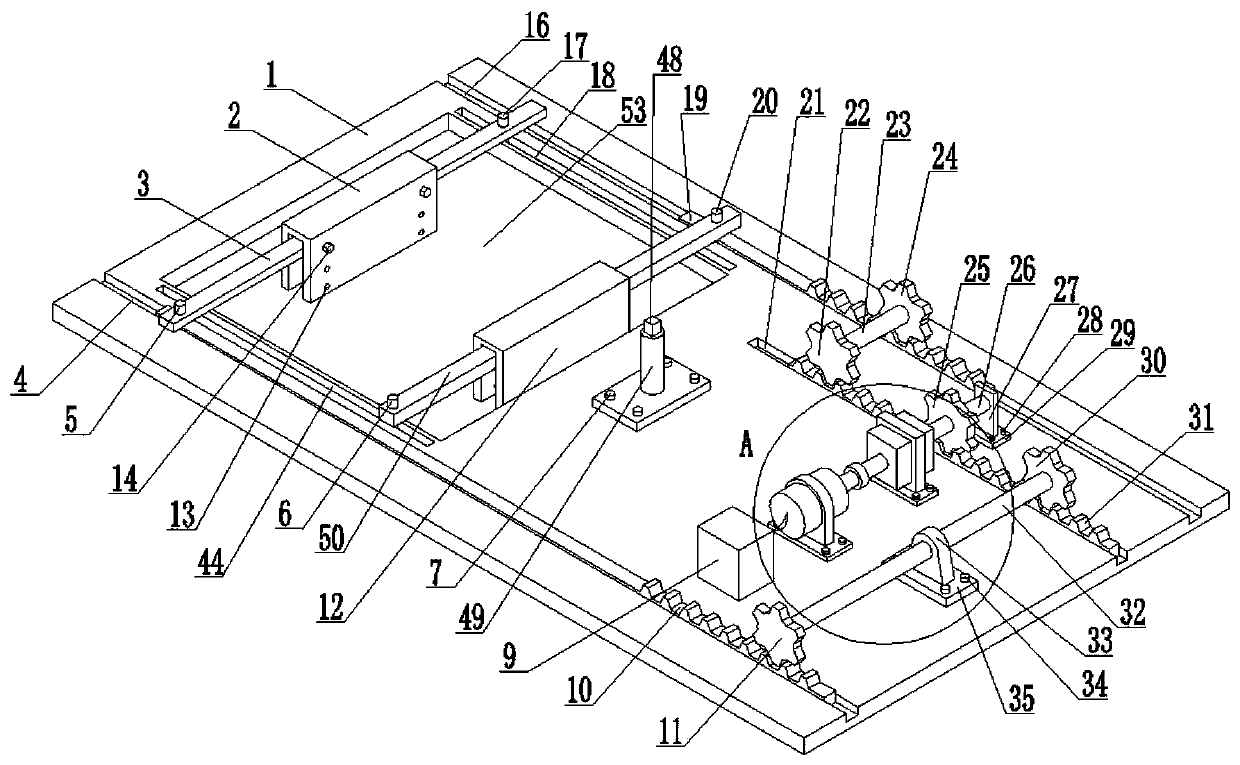

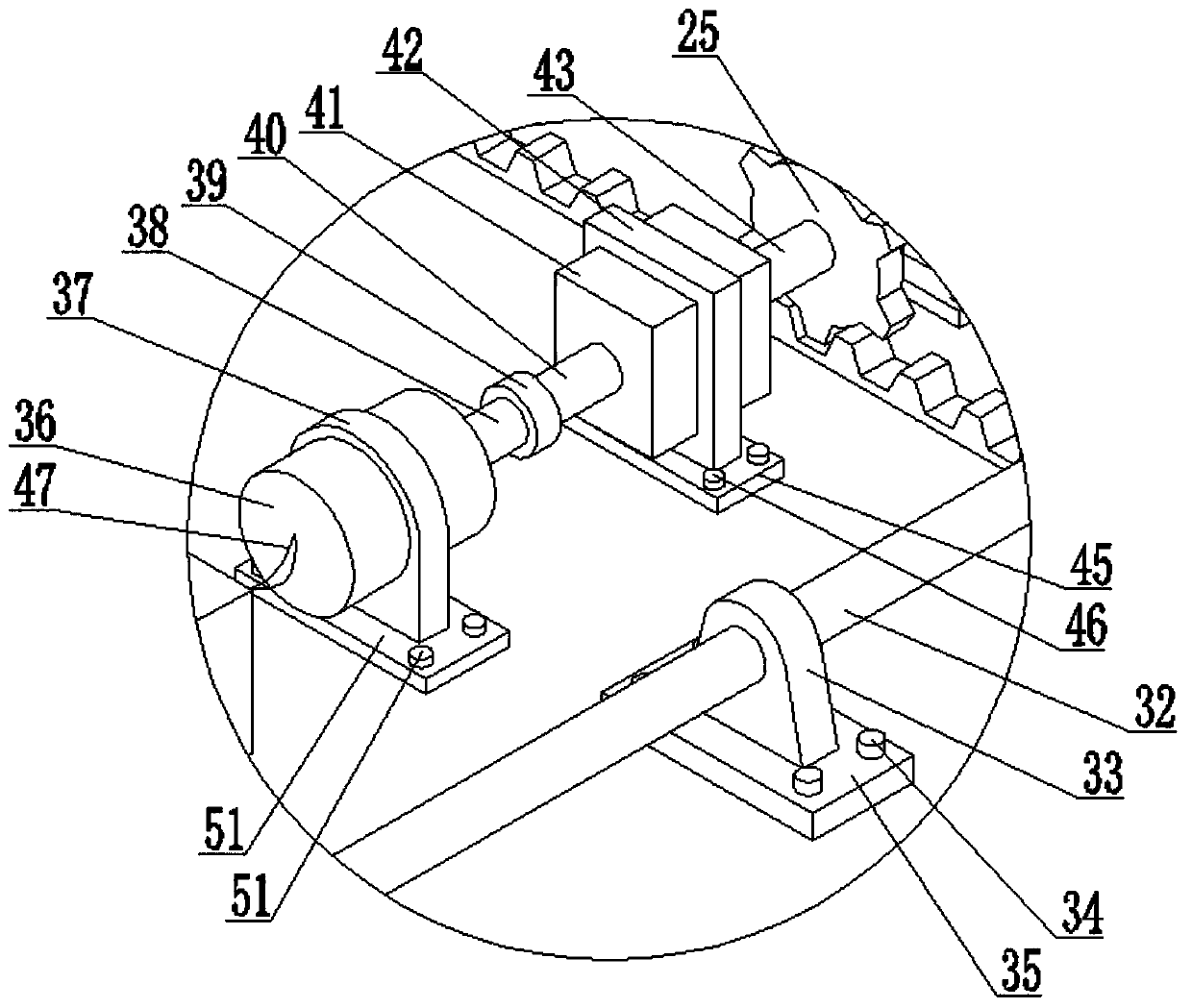

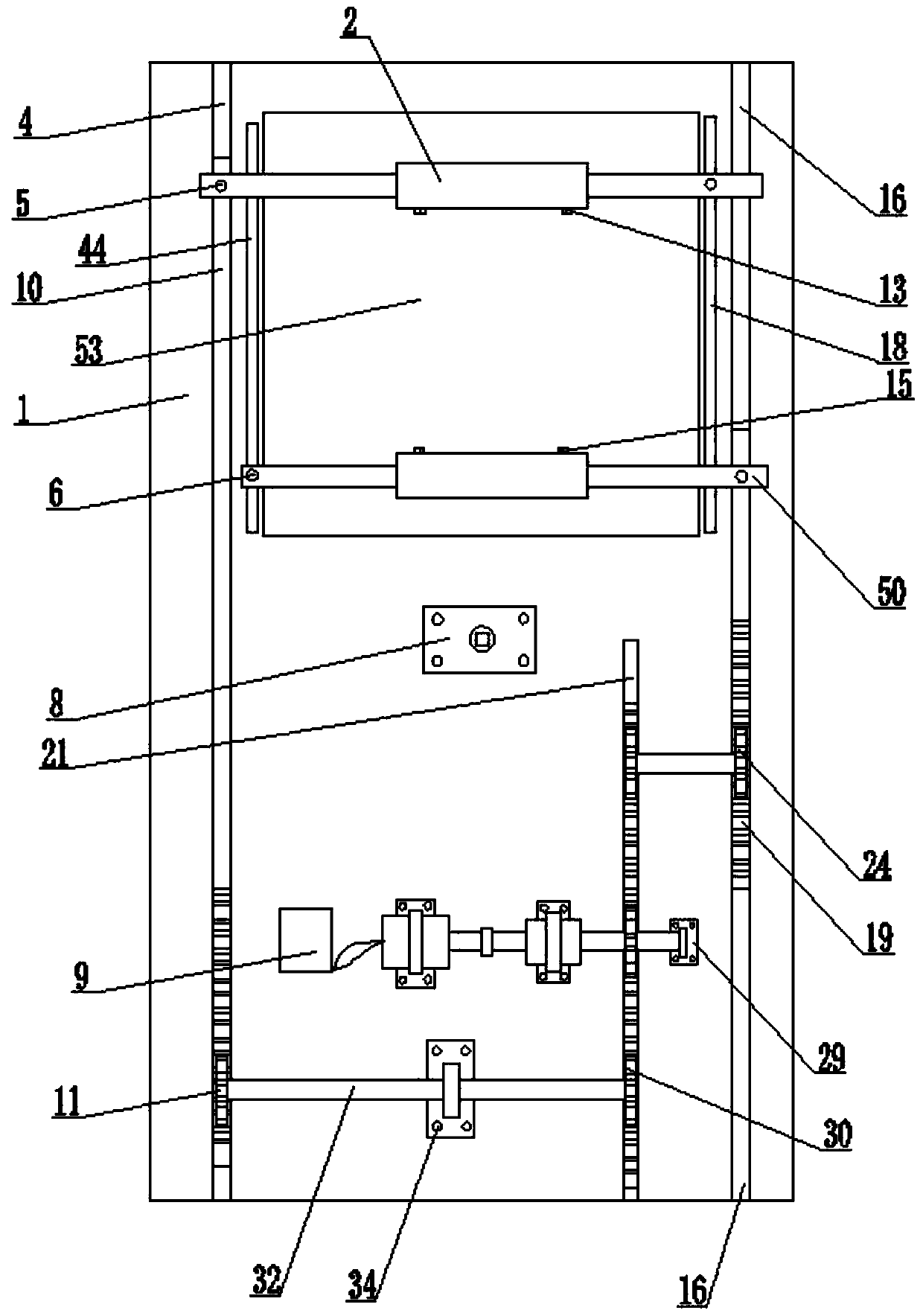

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] refer to Figure 1 to Figure 5A stamping die for an automobile chassis provided by the present invention includes a base plate 1, a first sliding support rod 3, a second sliding support rod 50, a motor 36, and a reducer 41. The base plate 1 is provided with a first bottom plate 8, The second base plate 29, the third base plate 35, the fourth base plate 45 and the fifth base plate 51, the top of the first sliding support bar 3 is provided with the first mold 2, the left and right sides of the first sliding support bar 3 The sides are respectively fixed with the first left sliding column 5 and the first right sliding column 17, the bottom of the first right sliding column 17 is in contact with the first right chute 18 and can follow the first right chute 18 The length direction moves linearly; the top of the second sliding support bar 50 is provided with a second mold 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com