A Method for Controlling the Secondary Cooling Water Volume of Billet Continuous Casting under High Casting Speed

A billet continuous casting and control method technology, which is applied in the field of continuous casting, can solve the problems of unfavorable rolling mill quality control, high temperature loss of slab, unfavorable rapid growth of slab shell, etc., so as to improve energy utilization efficiency and temperature gradient Uniform distribution, conducive to the effect of rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

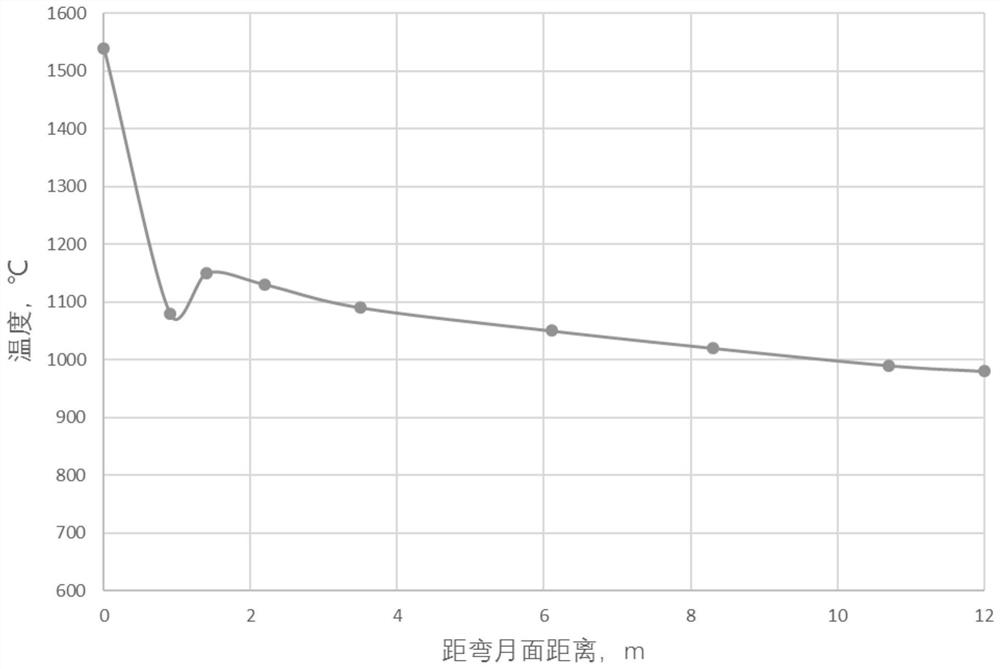

[0022] A full-arc continuous casting machine is used to produce slabs with a cross-section of 160mm × 160mm. There are 7 cold zones, and the water volume of each cold zone is individually controlled. The steel grade is HRB400, and the working speed is 5.0m / min.

[0023] The control method is as follows: the strong cooling area is the first section of the second cooling area, with a length of 2.6m, including cold zone 1, cold zone 2, cold zone 3, and water nozzle cooling, and the cooling water flow densities of cold zones 1 to 3 are respectively 26L / (m 2 ·s), 21L / (m 2 ·s), 18L / (m 2 s), the cooling water pressure is 2.0MPa; the return temperature area is the rear section of the second cooling zone, with a length of 8m, including cold zone 4, cold zone 5, cold zone 6, cold zone 7, water nozzle cooling, cold zone 4-7 The cooling water flow densities are 8L / (m2 s), 4L / (m 2 ·s), 2L / (m 2 ·s), 0.5L / (m 2 ·s), cooling water pressure 1.0MPa.

[0024] like figure 1 , 2 As shown i...

Embodiment 2

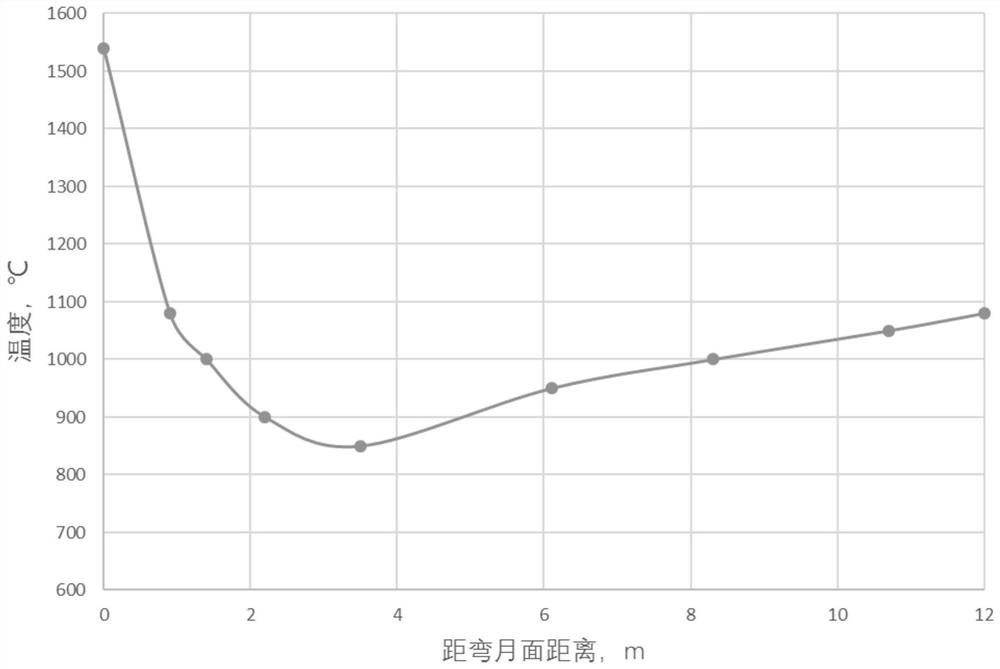

[0026] A full-arc continuous casting machine is used to produce a slab with a cross-section of 160mm×160mm. There are 9 cold zones, and the water volume of each cold zone is controlled separately. The steel grade is HRB400, and the working speed is 7.0m / min.

[0027] The control method is as follows: the strong cooling area is the front section of the second cooling area, with a length of 3.8m, including cold zone 1, cold zone 2, cold zone 3, cold zone 4, water nozzle cooling, and cooling water flow in cold zones 1 to 4. The density is 42L / (m respectively 2 ·s), 31L / (m 2 ·s), 23L / (m 2 ·s), 19L / (m 2 s), the cooling water pressure is 2.0MPa; the return temperature area is the rear section of the second cooling zone, with a length of 9.5m, including cold zone 5, cold zone 6, cold zone 7, cold zone 8, cold zone 9, and air-water nozzle cooling , the cooling water flow density of cold zones 5 to 9 is 9.5L / (m 2 ·s), 5L / (m 2 ·s), 3L / (m 2 ·s), 2L / (m 2 ·s), 0.8L / (m 2 ·s), coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com