Sandstone similar material based on freeze-thaw cycle model tests and preparation method thereof

A similar material, freeze-thaw cycle technology, applied in the preparation of test samples, ceramic products, other household appliances, etc., can solve the problems of similar mechanical properties, shrinkage and expansion differences, etc., to achieve stable properties, strong cementing ability, and reliability High adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

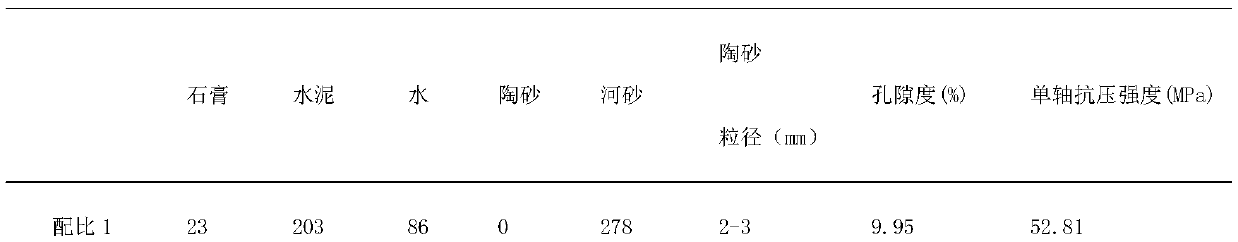

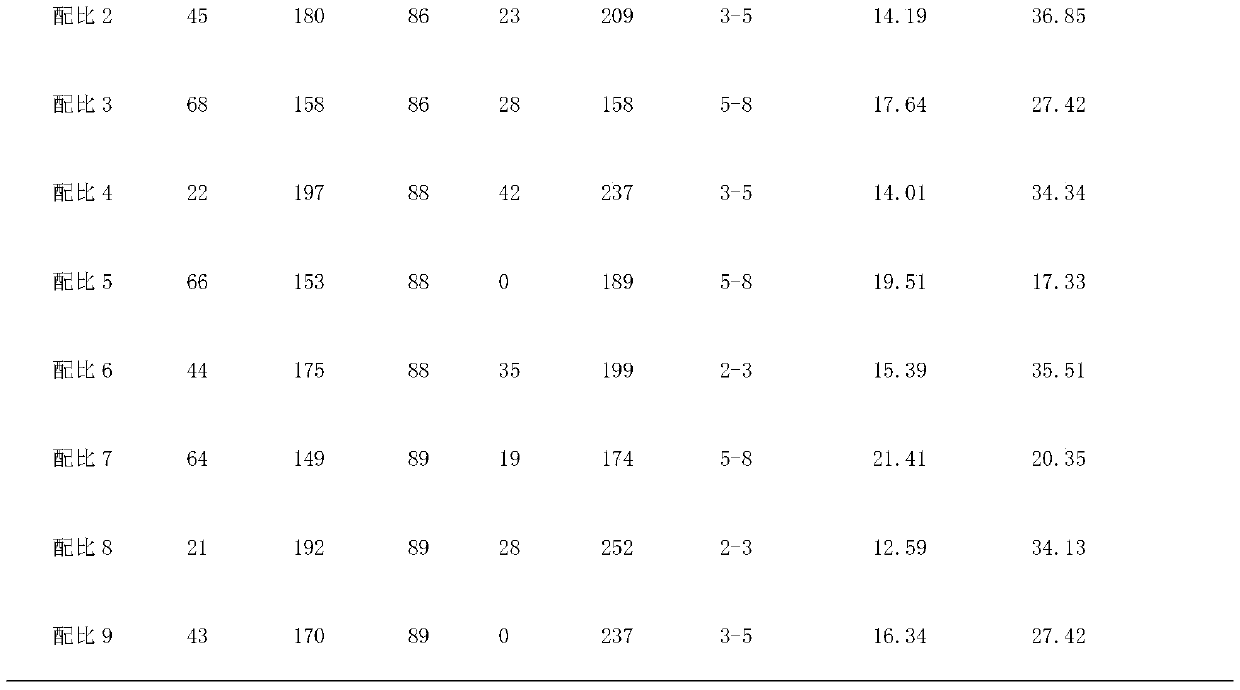

[0023] A sandstone-like material based on a freeze-thaw cycle model test and a preparation method thereof, comprising: by weight, 186-280 parts of aggregate, 213-225 parts of cement, and 86-89 parts of water;

[0024] Preferably, the aggregate includes 158-278 parts of standard river sand, 0-35 parts of 40-80 mesh pottery sand, 0-42 parts of 32-40 mesh pottery sand, and 0-28 parts of 20-32 mesh pottery sand.

[0025] Preferably, the cement used in the aggregate is prepared by mixing 21-68 parts of gypsum and 149-203 parts of cement.

[0026] Preferably, a method for preparing sandstone-like materials based on a freeze-thaw cycle model test, comprising:

[0027] (1): Take cement, gypsum, river sand, and distilled water according to the above ratio and put them into a container and stir evenly;

[0028] (2): Pour the mixture obtained in S1 into a grinding tool for compaction, wherein: each group of experiments has 6 test pieces, and 3 of them are used for the uniaxial compressi...

example 1

[0033] The sandstone-like model material raw materials of this example include: by weight, 278 parts of aggregate, 226 parts of cement, and 86 parts of water, wherein the cement includes 23 parts of gypsum and 203 parts of cement.

[0034] The preparation method of the sandstone similar model of this implementation case includes:

[0035] (1): Take cement, gypsum, river sand, and distilled water according to the above ratio and put them into a container and stir evenly;

[0036] (2): Pour the mixture obtained in S1 into a grinding tool and compact it, (6 test pieces for each group of experiments, 3 for the uniaxial compressive strength measurement (average value) before freezing and thawing, and 3 for freezing and thawing. Uniaxial compressive strength measurement after melting), remove the mold after curing for 24 hours, and cure in water for 14 days, you can get the similar material of sandstone;

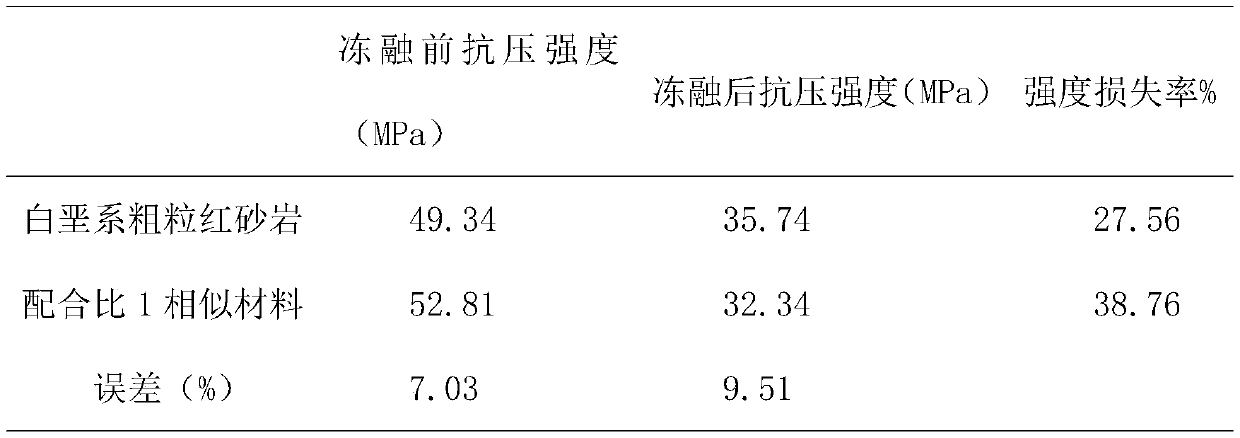

[0037] (3): Measure the uniaxial compressive strength of sandstone similar m...

example 2

[0040] The raw materials of the sandstone similar model material of this example include: by weight, 232 parts of aggregate, 225 parts of cement, 86 parts of water, wherein cement comprises 45 parts of gypsum, 180 parts of cement; aggregate comprises 209 parts of river sand, 32- 23 parts of 40 mesh pottery sand.

[0041] After saturating the pottery sand with water, repeat the preparation steps in Example 1 to obtain the compressive strength of sandstone similar materials;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com