Patents

Literature

37results about How to "The physical and mechanical properties remain stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron spar powder, guartz sand cement rock-soil similar material and preparation process thereof

The invention relates to a method to produce equivalent material of iron crystal sand cemented rock soil that uses iron ore, barite powder and quartz sand as main aggregate, uses solution that is made up from rosin and alcohol as cementing agent, and uses gesso as regulator. Whisking the iron ore, barite powder and quartz sand, gesso, resin-alcohol solution to equal, pouring into steel mould, pressing the mixture, opening the mould, drying for 2-3 days, the invention could be gained. The invention has the advantages of high unit weight, large range of mechanics parameter, easy to process and low cost.

Owner:SHANDONG UNIV

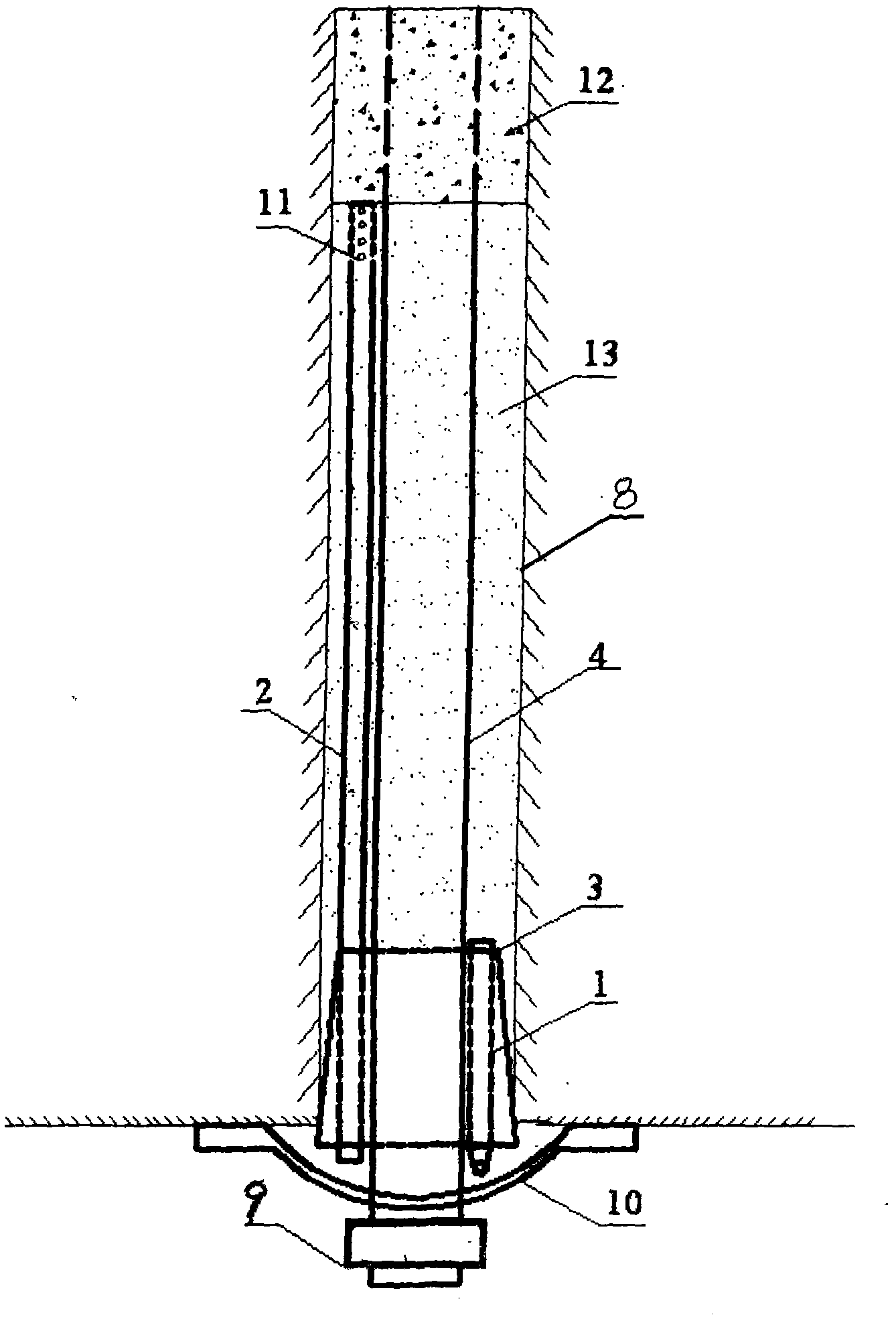

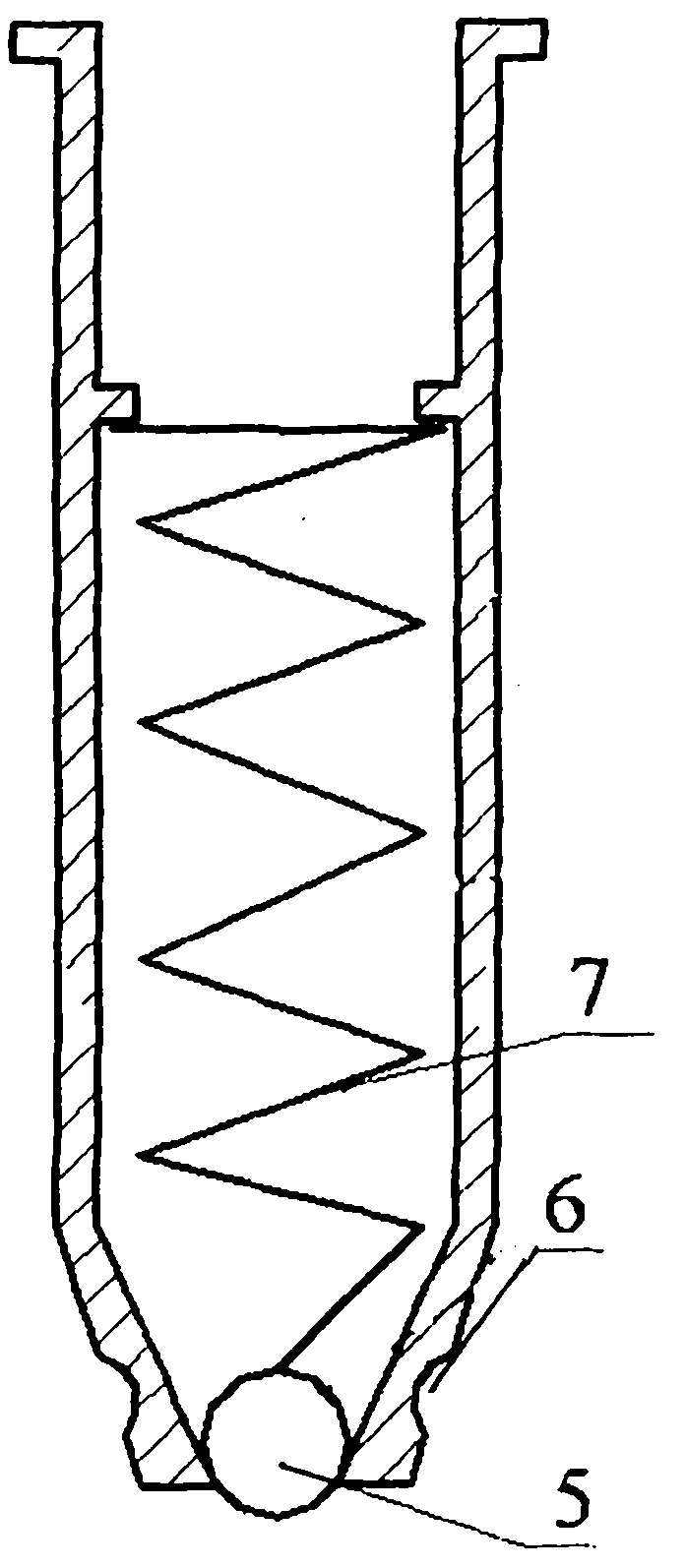

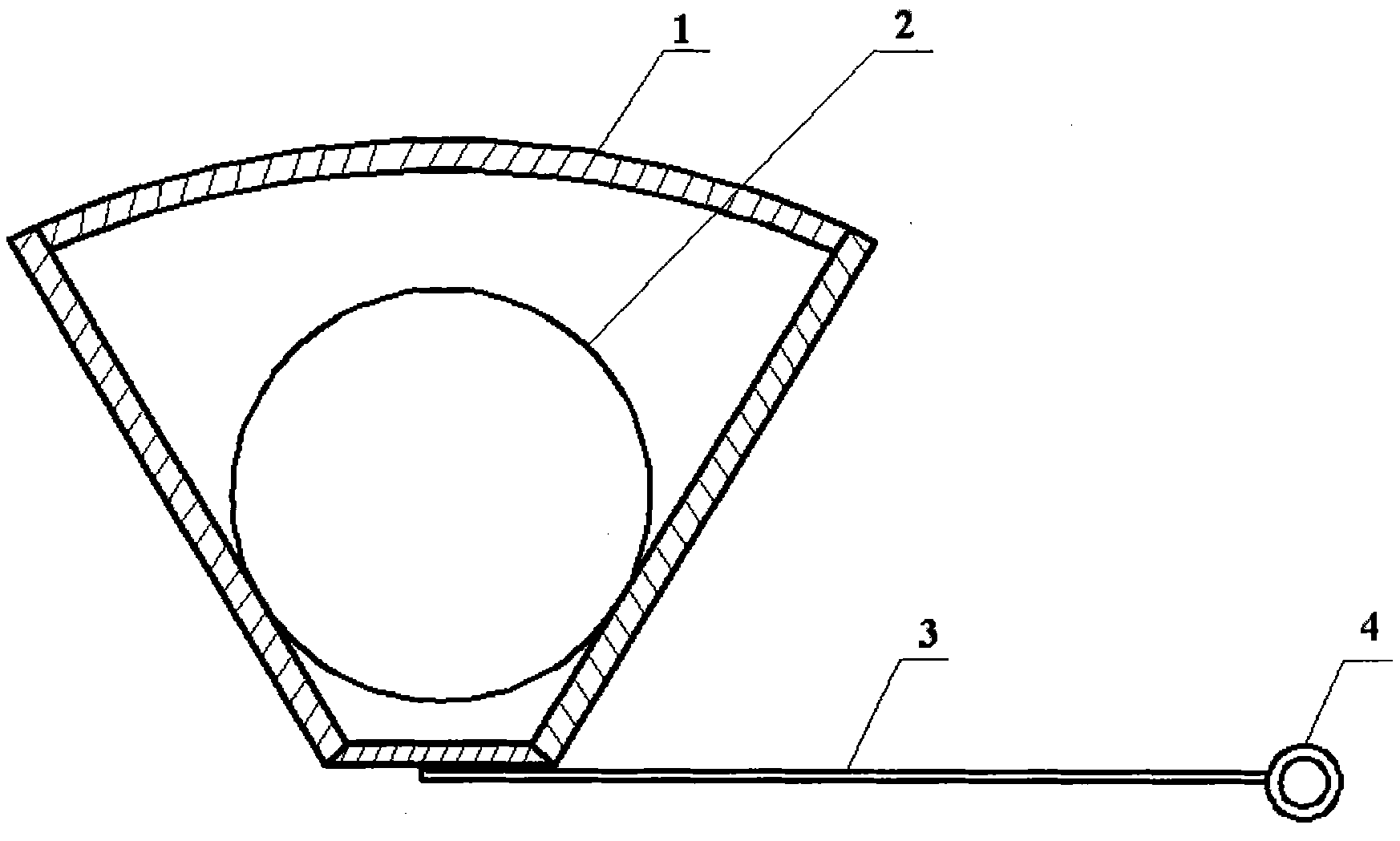

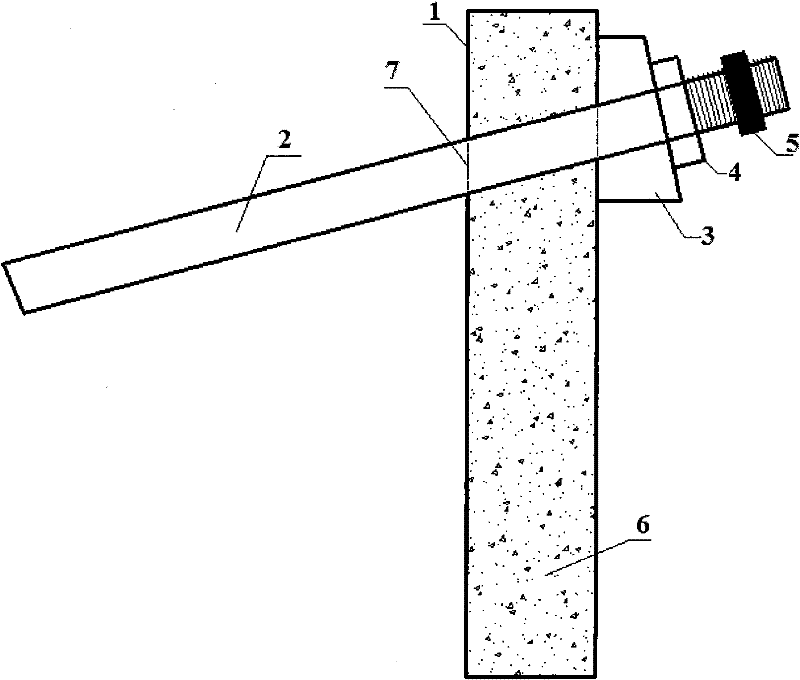

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

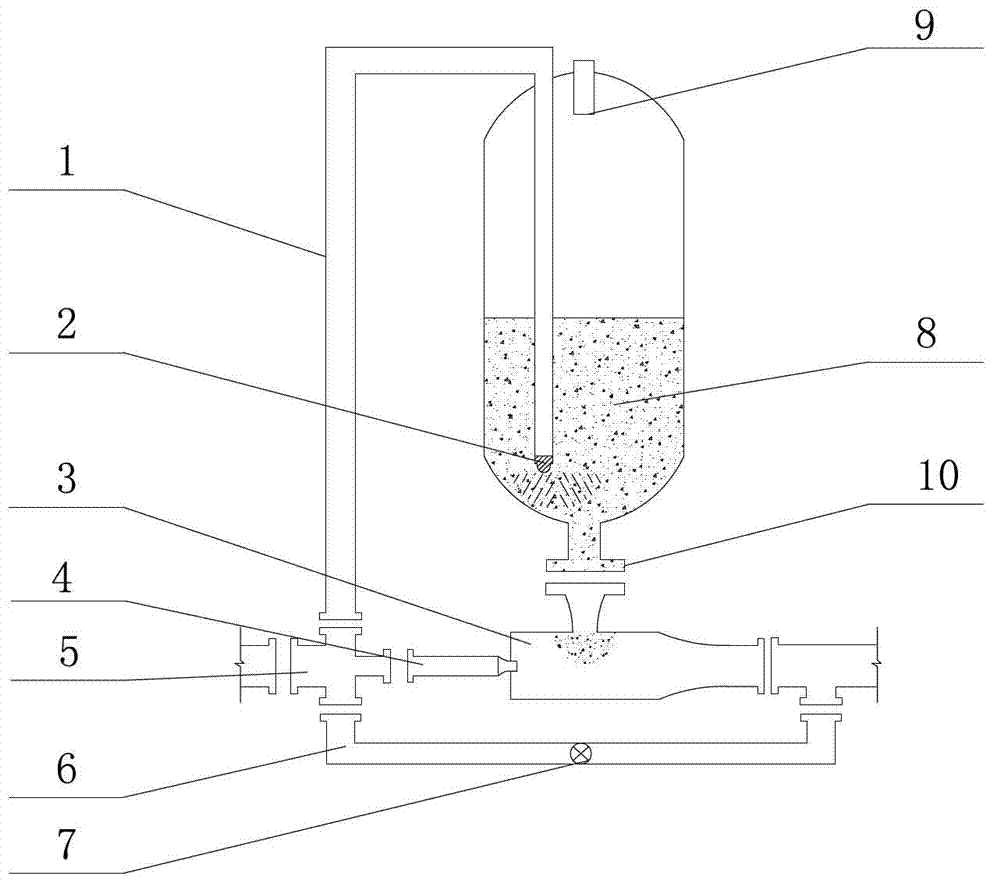

Negative-pressure jet-type particle impact drilling injection device

InactiveCN103195363AGood effectSolve easy blockageSpray nozzlesDrilling machines and methodsPetroleumHigh pressure

The invention belongs to the technical field of petroleum drilling engineering and particularly relates to a negative-pressure jet-type particle impact drilling injection device. A balanced-pressure jet pipe is installed on one side of a material inlet at the top of a high-pressure particle injection tank, a jet anti-blocking sprayer is arranged at one end of the balanced-pressure jet pipe, the other end of the balanced-pressure jet pipe is arranged at the top of a main pipe manifold, the jet anti-blocking sprayer is arranged at the bottom of the high-pressure particle injection tank, a negative-pressure particle injection pipe is arranged at the bottom of a material outlet, a nozzle is arranged at one end of the negative-pressure particle injection pipe and communicated with the main pipe manifold, a regulating pipe is arranged at the bottom of the main pipe manifold, the tail end of the regulating pipe is communicated with an outlet of the negative-pressure particle injection pipe, and a regulating valve is arranged in the regulating pipe. The negative-pressure jet-type particle impact drilling injection device adopts the self-rotating type jet anti-blocking sprayer, achieves omnibearing and multi-angle stirring on the material outlet of the high-pressure particle injection tank, is easy, convenient and safe to operate, serves as one of three core systems of the particle impact drilling new technology, and is simple in processing and manufacturing, convenient to detach, stable in performance and capable of remarkably improving the drilling speed of extra-hard wear-resisting stratum of deep well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

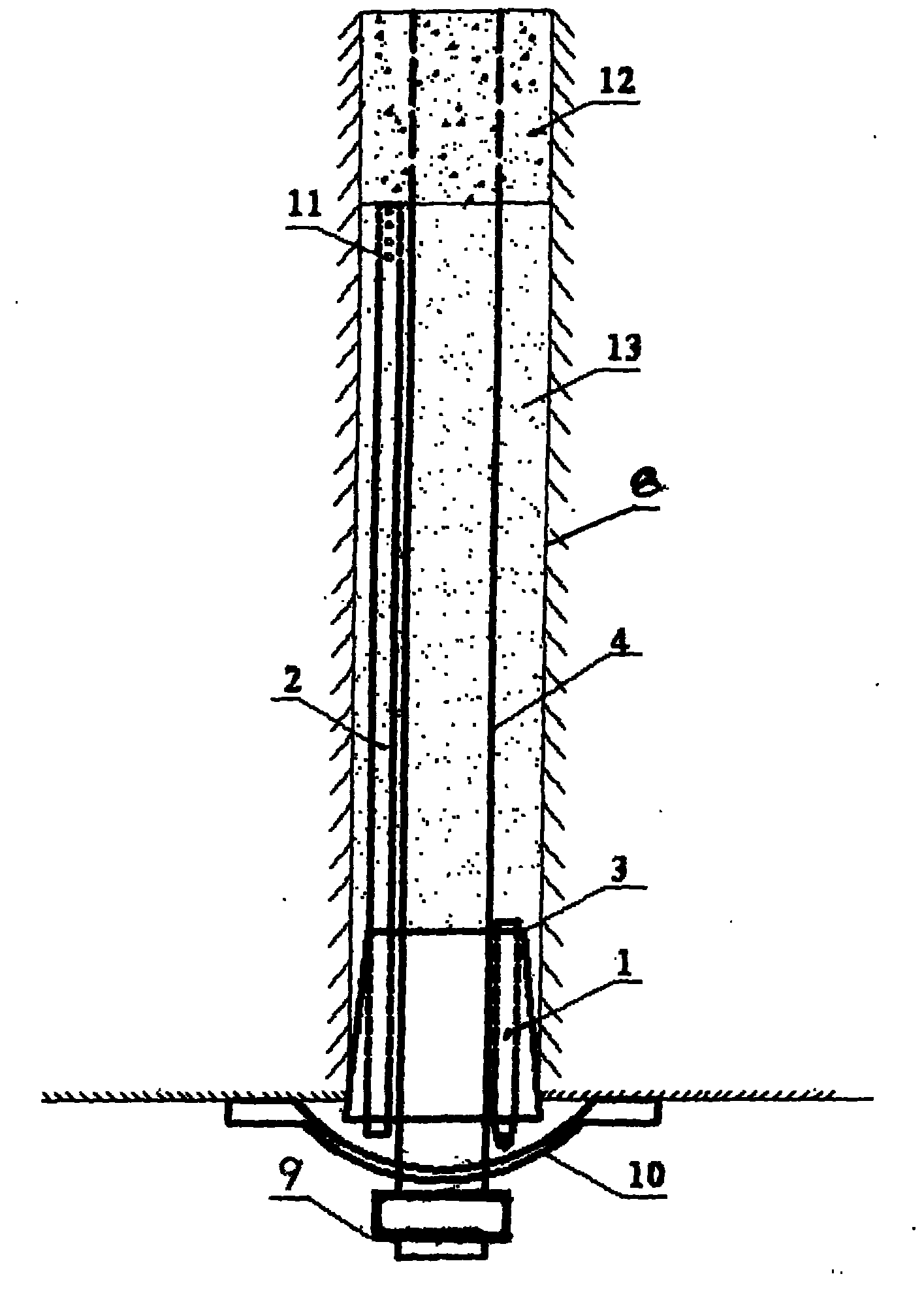

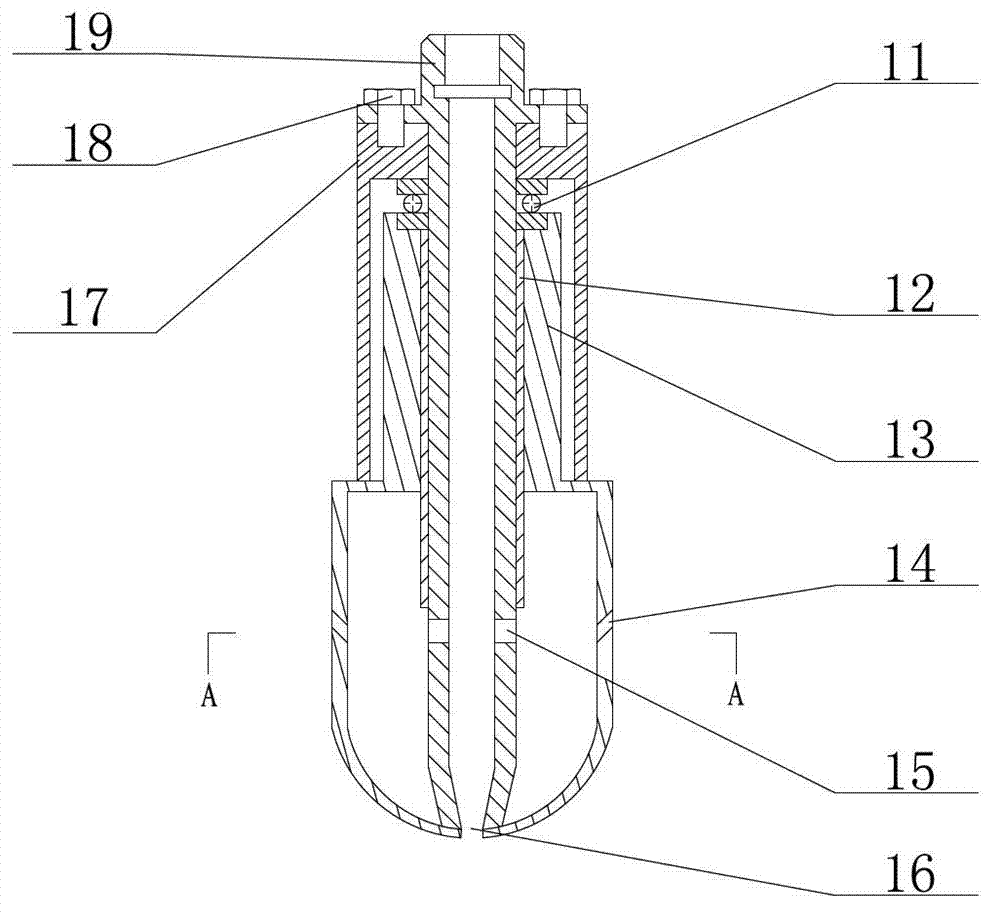

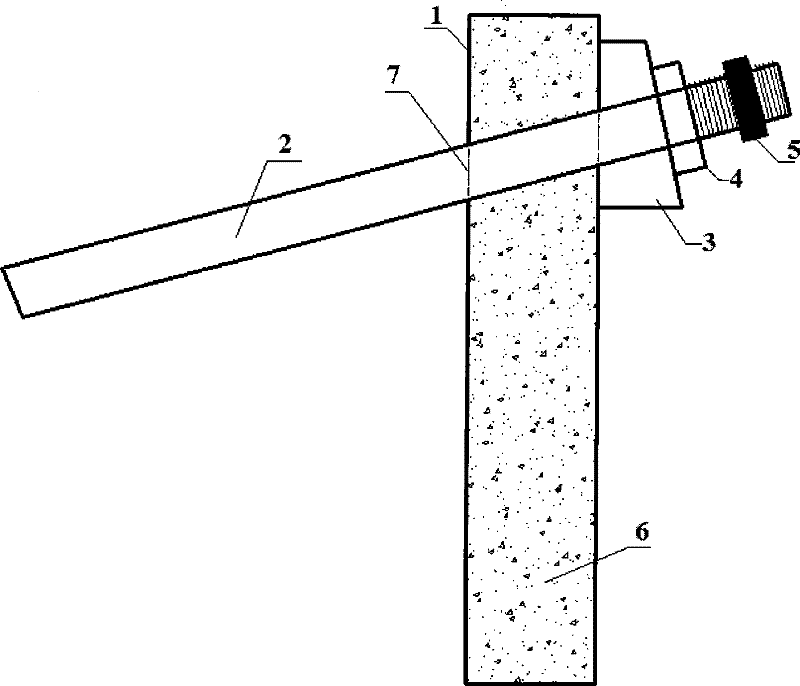

Self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method

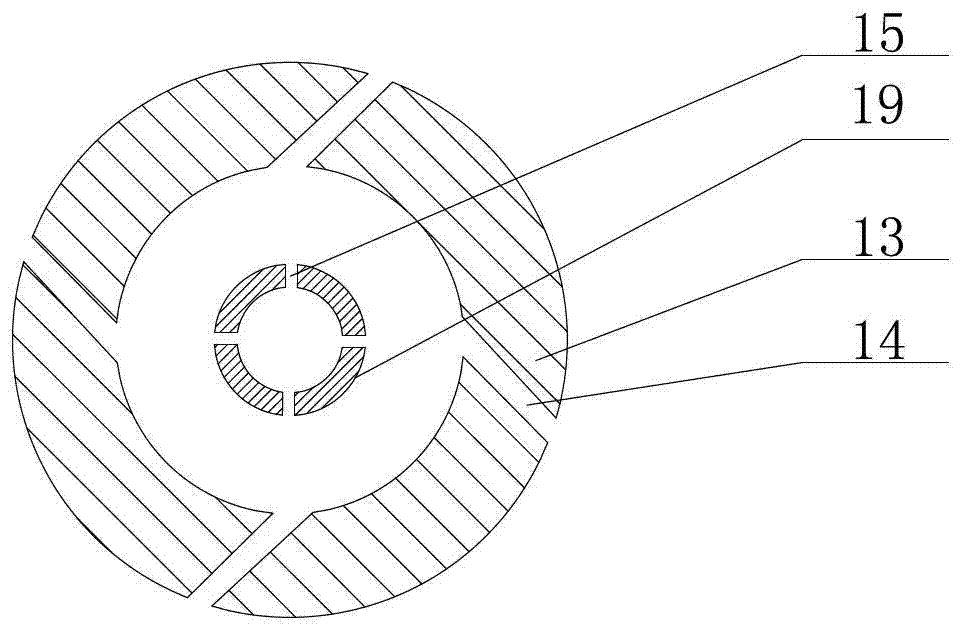

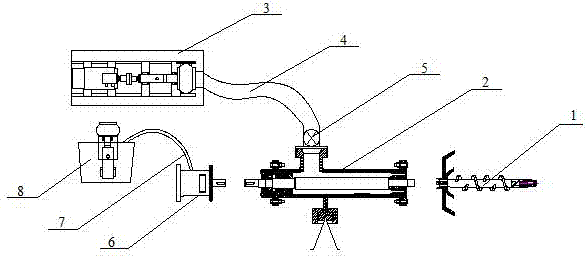

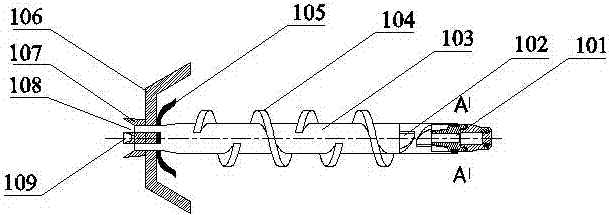

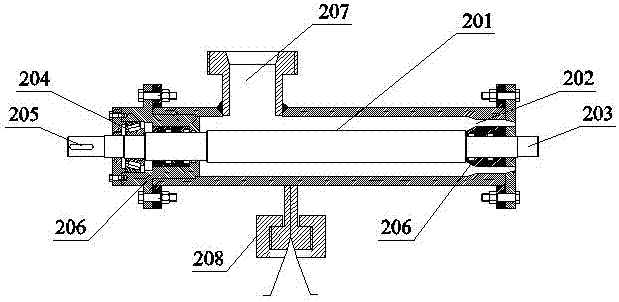

PendingCN107476814AImprove rock drilling or rock breaking efficiencyDrilling speed is fastAnchoring boltsDrill bitHigh pressure

The invention discloses self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method. The equipment is composed of a self-vibrating flow-jetting and grouting anchor rod, a high-pressure rotary slurry mixing device, a grouting device and a hydraulic driving device. The self-vibrating flow-jetting and grouting anchor rod is a hollow rod body with a screw-edge stirring piece, and the front end of the anchor rod is provided with a vibration generator which is connected with a drill bit; the upper portion of the high-pressure rotary slurry mixing device is provided with a feed hole, the bottom of the high-pressure rotary slurry mixing device is provided with a rotary supporting leg which can freely lift and rotate, the front portion of the high-pressure rotary slurry mixing device is provided with a flow-jetting spray pipe, an inner cavity is provided with a rotating shaft, the front end of the rotating shaft is provided with a connection plug, the connection plug is cooperated and connected with a connection inserted groove of the self-vibrating flow-jetting and grouting anchor rod, the rear end of the rotating shaft is provided with a bearing, and the two ends of the rotating shaft are provided with high-pressure sealing boxes. The grouting device adjusts the grouting amount and the grouting pressure at any time, and the hydraulic driving device provides rotating power. The equipment and the method is widely used in support and reinforcement engineering in mines, transportation, water conservancy and other engineering fields, the application prospect is broad and the economic benefit is remarkable.

Owner:BINZHOU UNIV

MDF(Medium-density fiber)-E1-level urea-formaldehyde resin adhesive

ActiveCN102775946AImprove water resistanceReduce releaseAldehyde/ketone condensation polymer adhesivesFiberStrong acids

The invention provides an MDF (medium density fiber)-E1-level urea-formaldehyde resin adhesive. Formaldehyde and urea are used as main materials; and urea is added by three batches, and the molar ratio of formaldehyde to urea is controlled to be respectively (2.4-3.0) to 1, (1.3-1.5) to 1, and (0.8-1.0) to 1 after each batch of urea is added. The glue preparation process adopts a weak base-medium strong acid-weak base reaction path, and the materials are reacted in three mediums of which the pH is 8.0-8.5, 2.5-3.5 and 8.0-8.5, respectively to finally prepare the MDF-E1-level urea-formaldehyde resin adhesive. By using the MDF-E1-level urea-formaldehyde resin adhesive to prepare an El-level medium-density fiber board, the effect of reducing the formaldehyde emission can be achieved without adding a formaldehyde catching agent or carrying out post ammonia water treatment.

Owner:广西高林林业股份有限公司

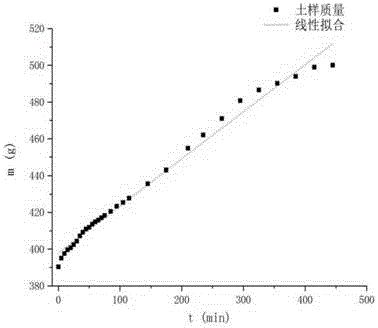

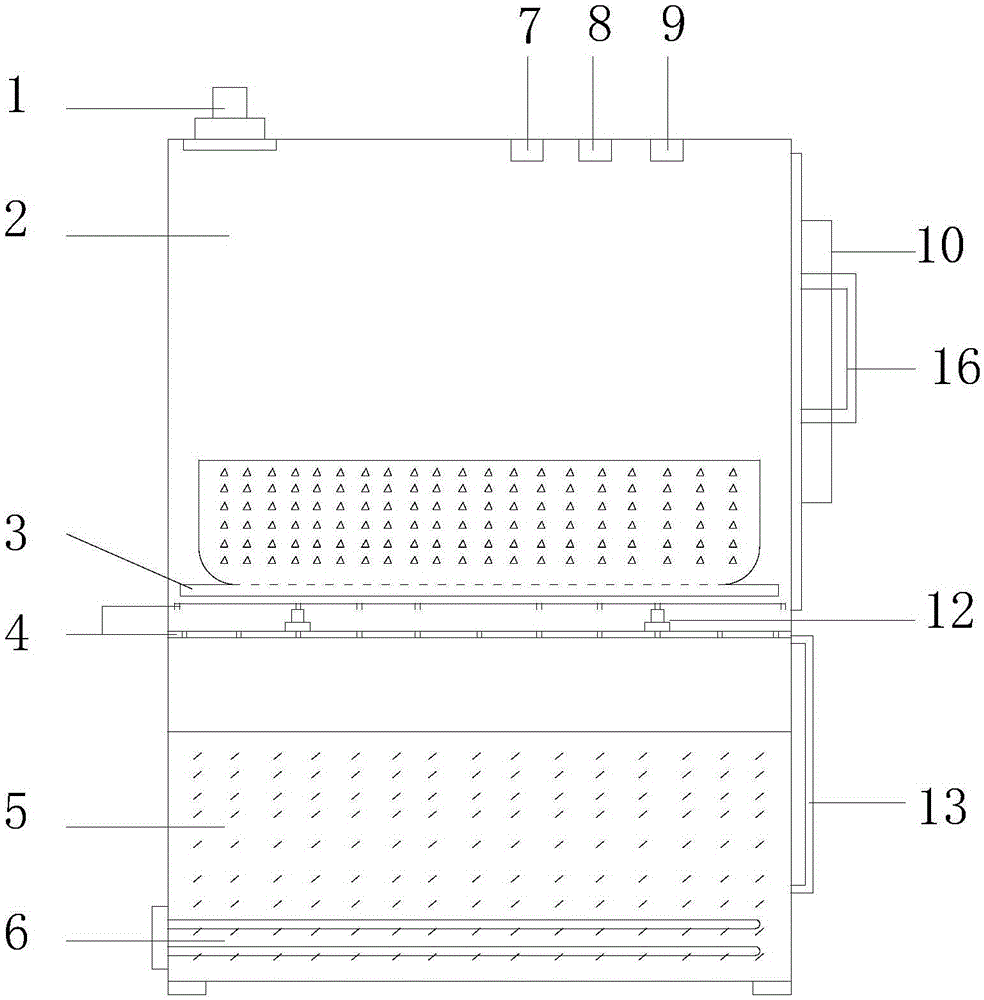

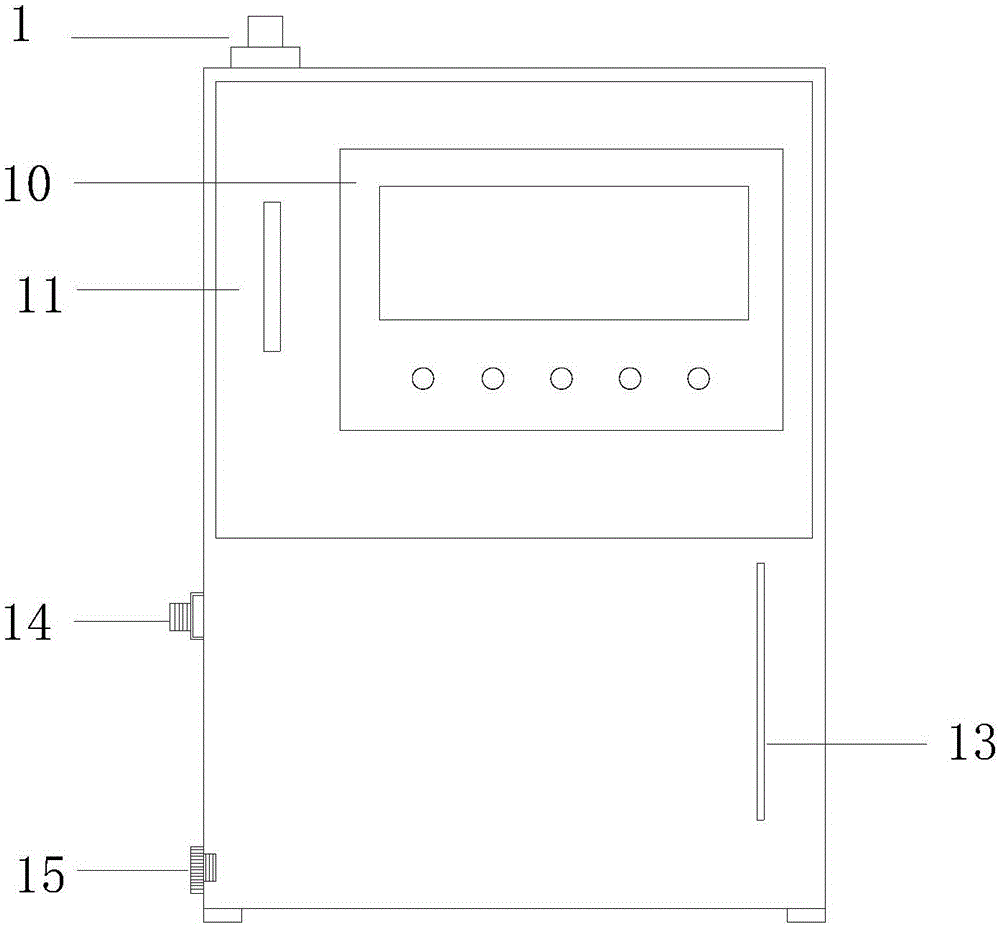

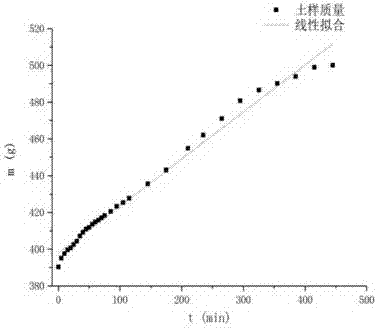

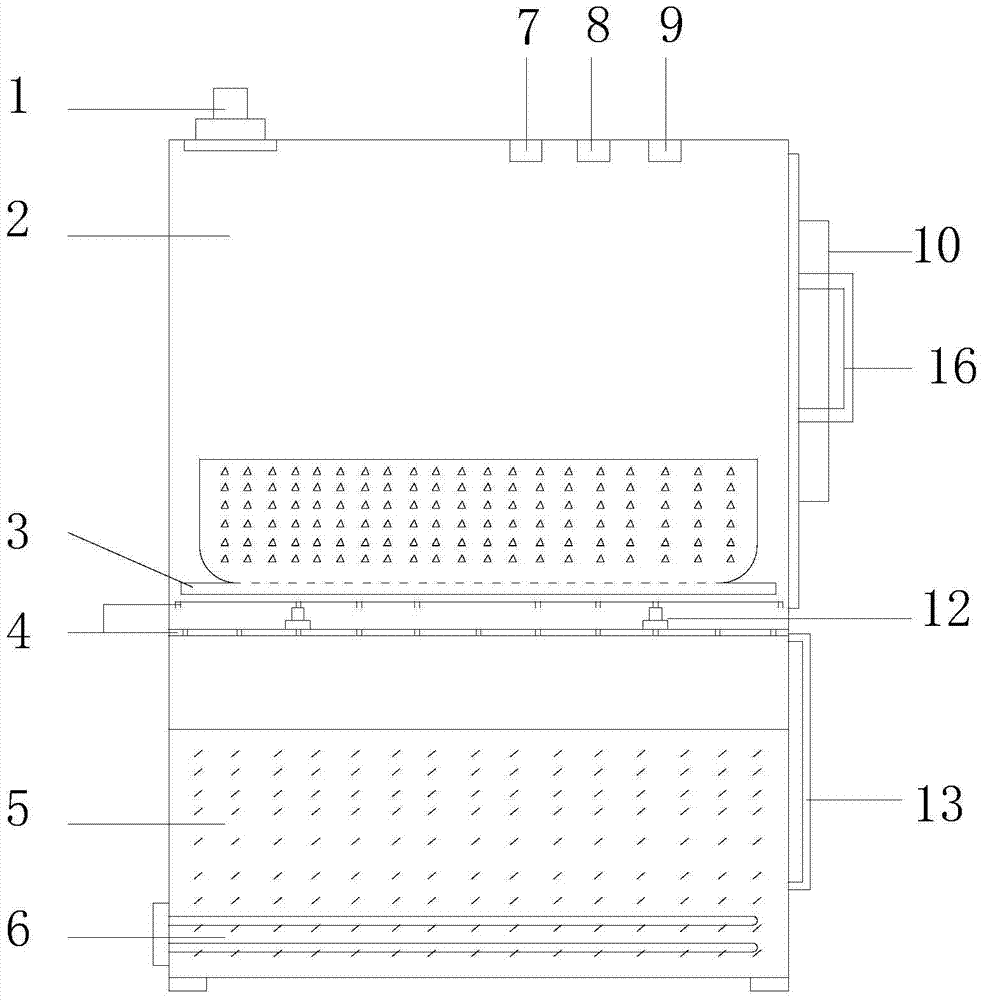

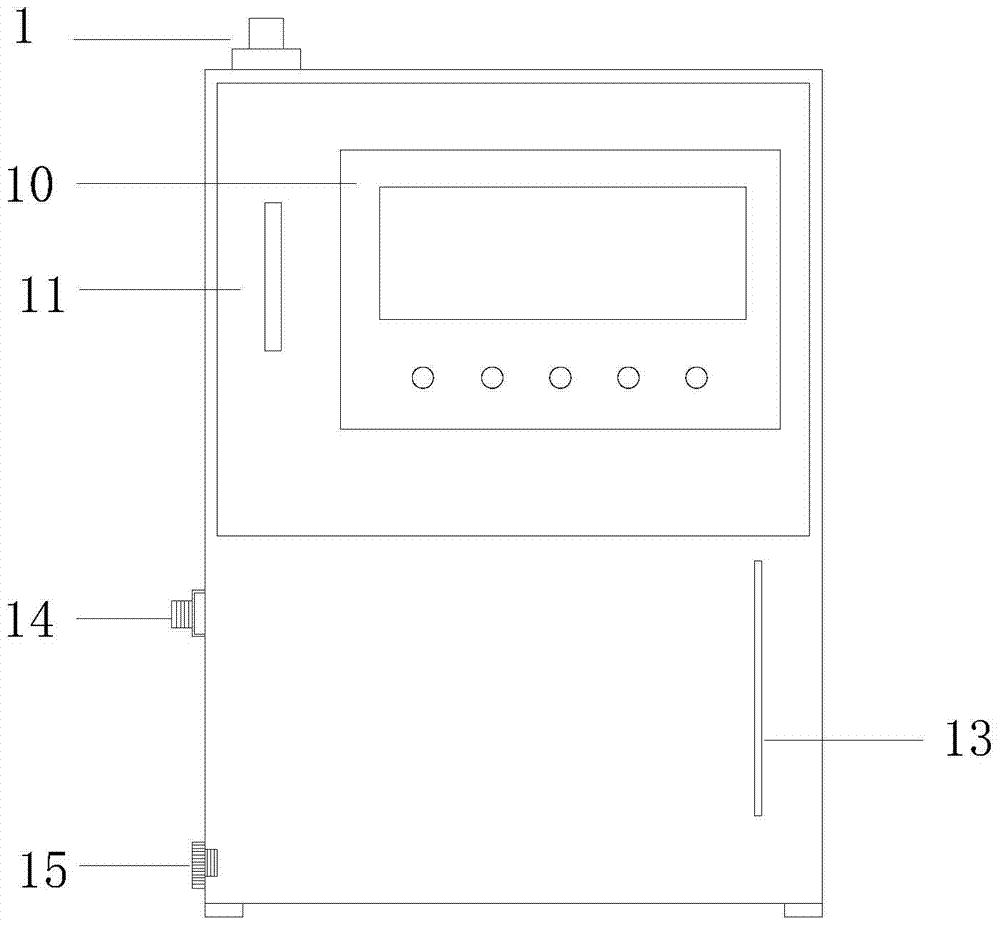

Making device for soil samples/rock samples with different moisture contents

ActiveCN105115796AUniform moisture contentReach moisture contentPreparing sample for investigationEngineeringMoisture

The invention relates to a making device for soil samples / rock samples with different moisture contents. The inside of the main case is a closed space, a bracket is disposed at the middle part in the main case, a weight detector is installed on the bracket, the weight detector is provided with a tray for weighing, the tray divides the space in the main case into an upper soil sample / rock sample placement space and a lower humidification space. The humidification space of the main case is internally equipped with a water tank, the water tank is internally provided with a heating unit, the main case is provided with a case door convenient put in and take out the soil sample / rock sample at the position where the soil sample / rock sample placement space is located, and the inside of the main case is equipped with an air pressure detector, a temperature detector and a humidity detector at the top of the soil sample / rock sample placement space. With the making device provided by the invention, the moisture states of the obtained soil samples / rock samples can be more uniform, the physical and mechanical properties of the soil samples / rock samples are stable and easy to control, also the operation process is simple, and the preparation efficiency is high.

Owner:CENT SOUTH UNIV

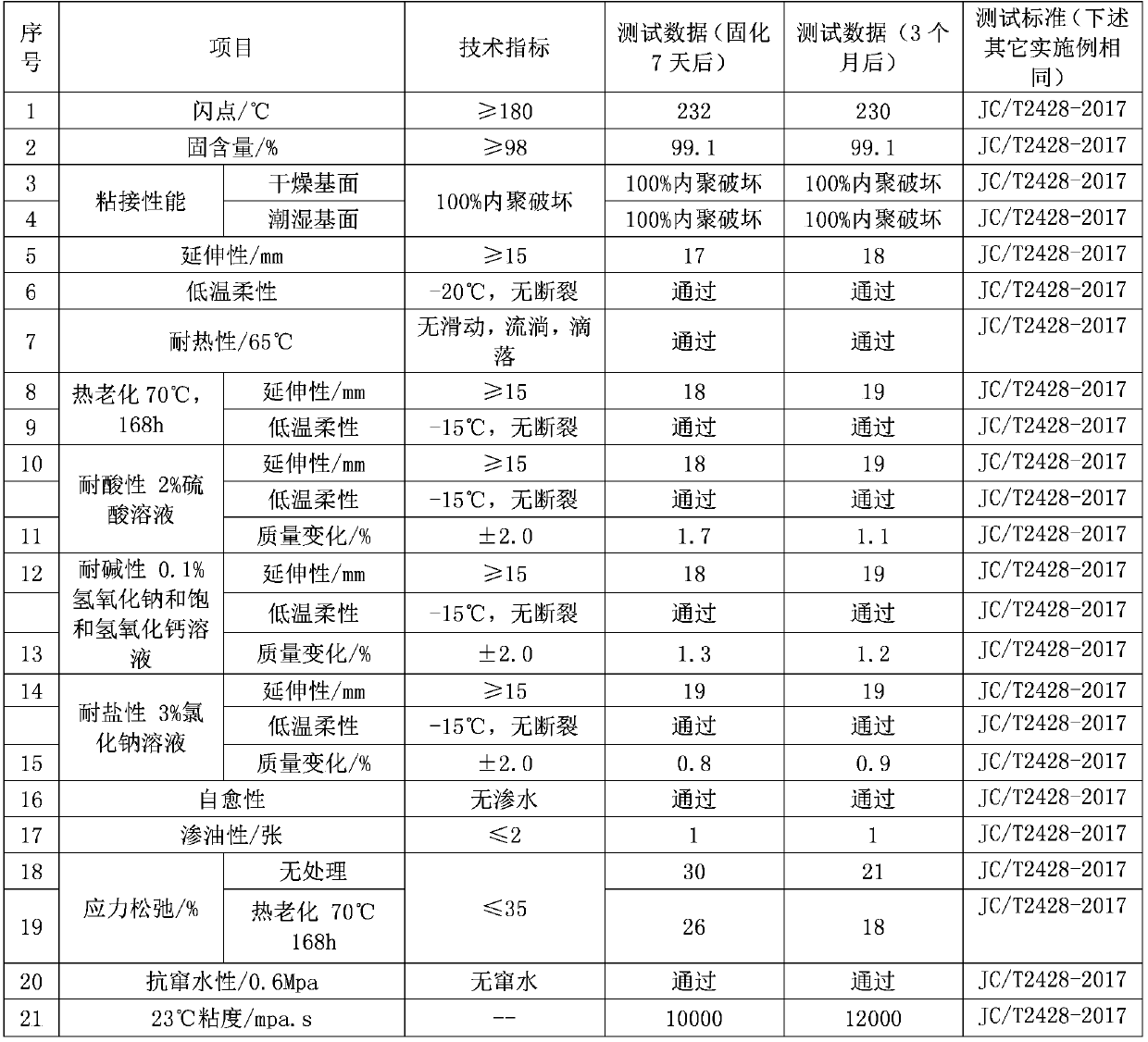

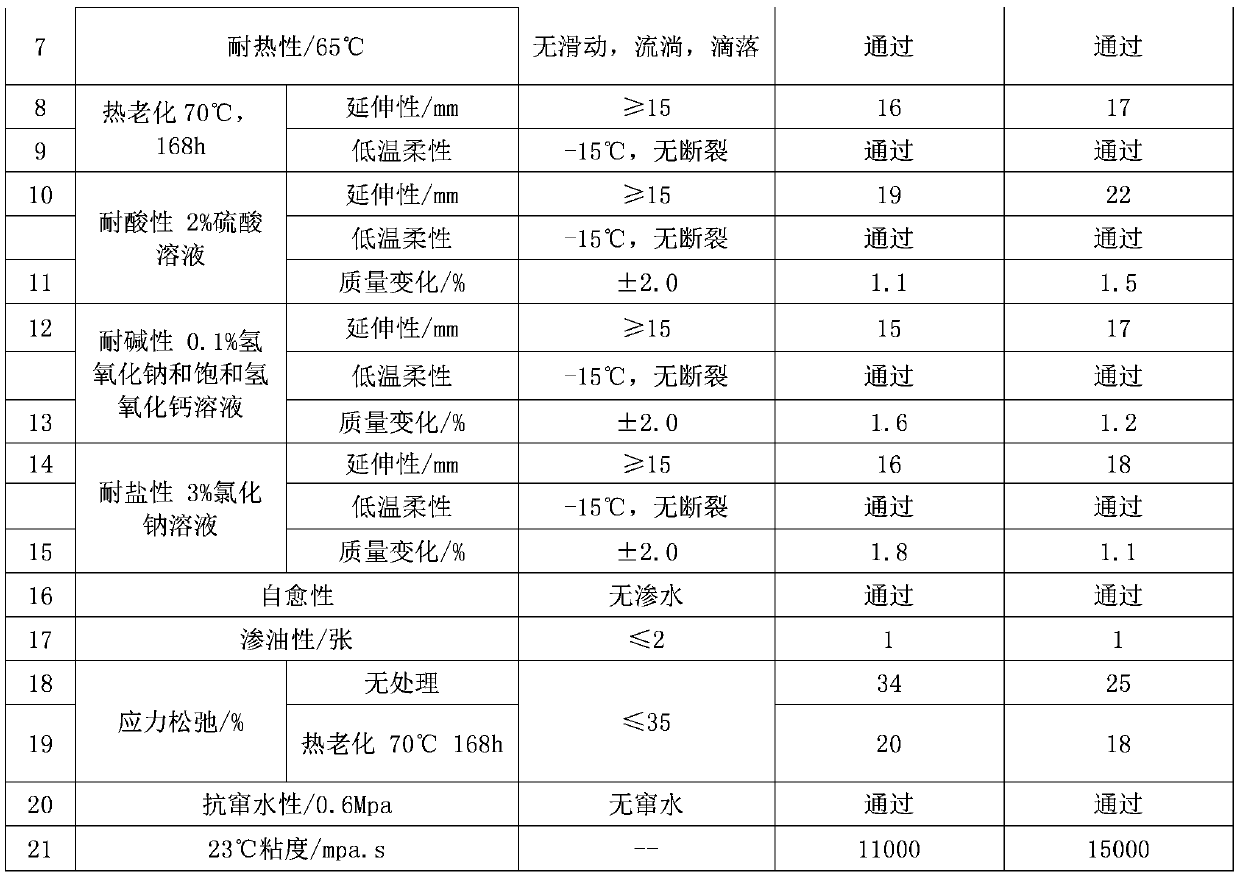

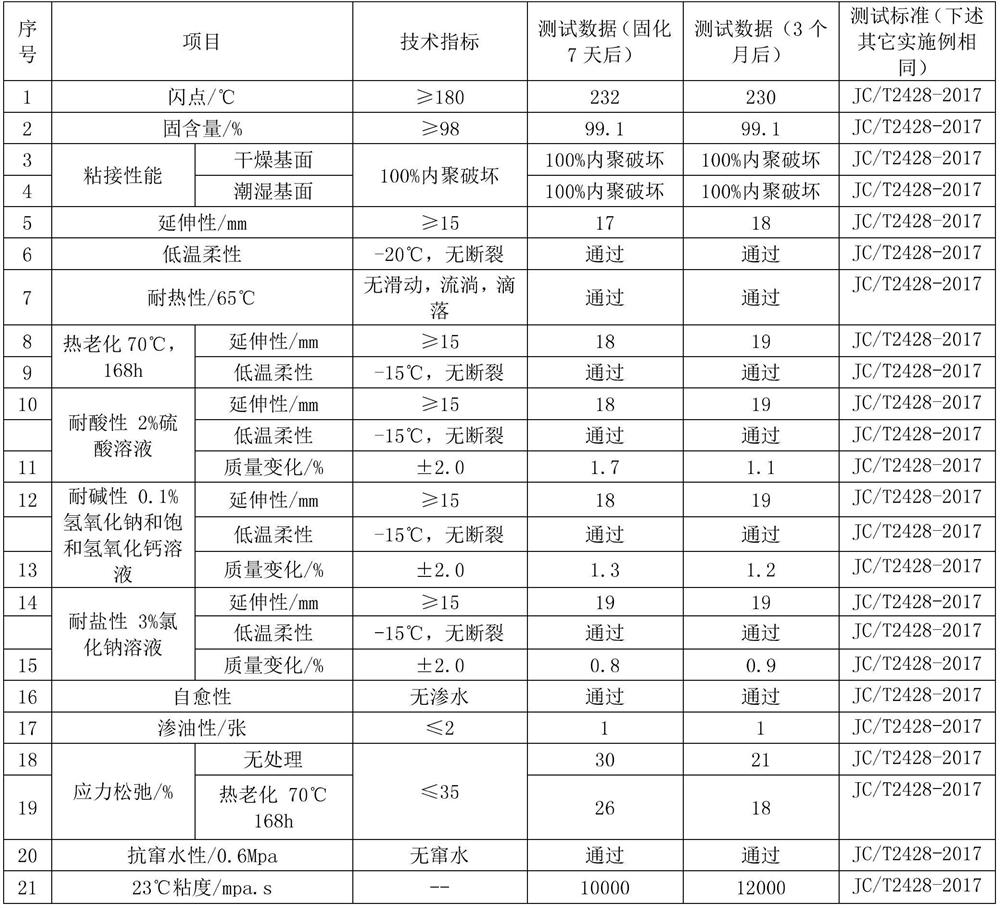

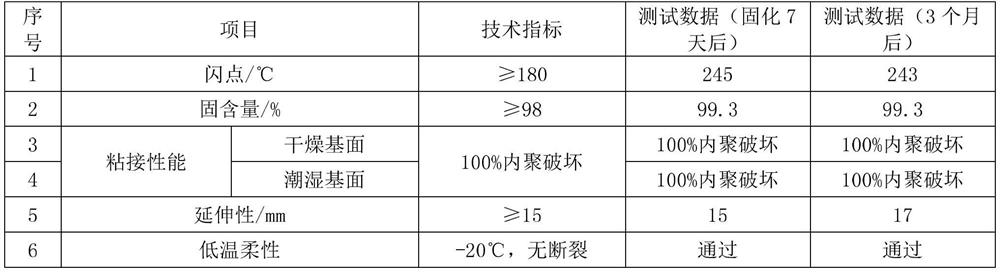

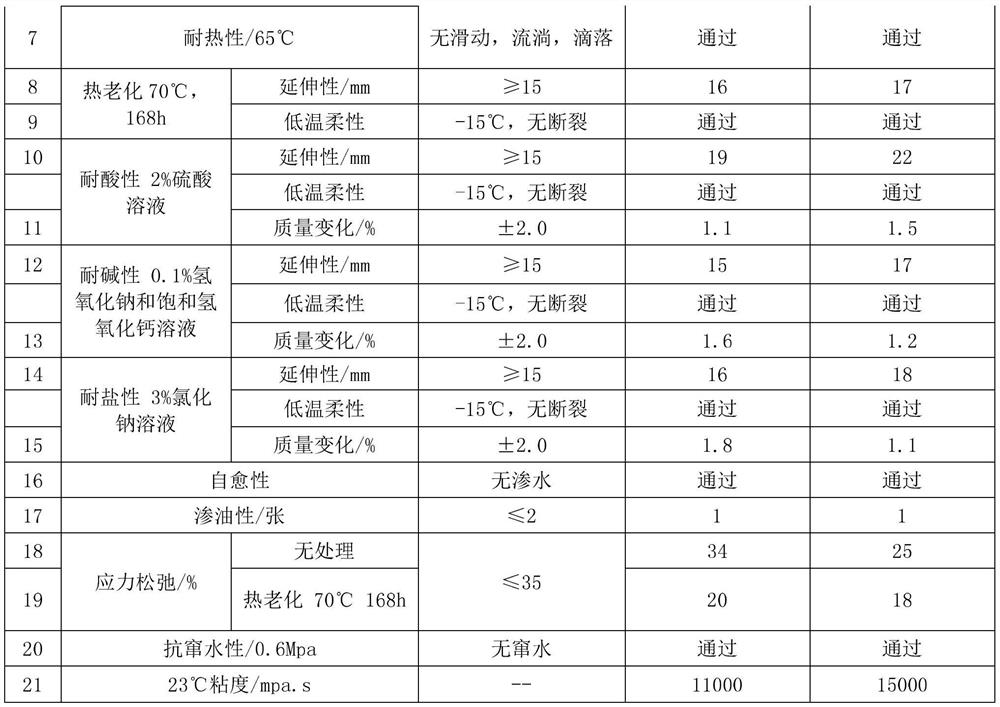

Two-component normal temperature non-curing asphalt polyurethane waterproof coating and preparation method thereof

ActiveCN110527424AImprove stabilityStable physicsPolyurea/polyurethane coatingsBituminous coatingsPolyolHydroxyl-terminated polybutadiene

The invention discloses a two-component polyurethane asphalt waterproof coating and a preparation method thereof. The waterproof coating comprises a component A and a component B. The component A comprises modified polyurethane prepolymer obtained by a reaction of polyurethane prepolymer with first hydroxyl-terminated polybutadiene, and the polyurethane prepolymer is prepared by a reaction of polyol and polyisocyanate; the component B is prepared from petroleum asphalt, second hydroxyl-terminated polybutadiene, and a secondary amine curing agent and / or a primary amine curing agent; the first and second hydroxyl-terminated polybutadiene are respectively and independently selected from one or more combinations of compounds in a formula (I) (please see the specification for the formula), of structural monomers in the formula (I), monomers represented by a account for 10-30%, monomers represented by b account for 50-70%, and monomers represented by c account for 10-30%; the preparation method comprises the following step that the components A and B are respectively prepared and then mixed to obtain the waterproof coating; and according to the waterproof coating, the non-curing effect at the normal temperature can be achieved, the coating has good stability, good dispersion uniformity can always be maintained, and the stability of physical and mechanical properties and other properties of the coating can be ensured.

Owner:JIANGSU CANLON BUILDING MATERIALS

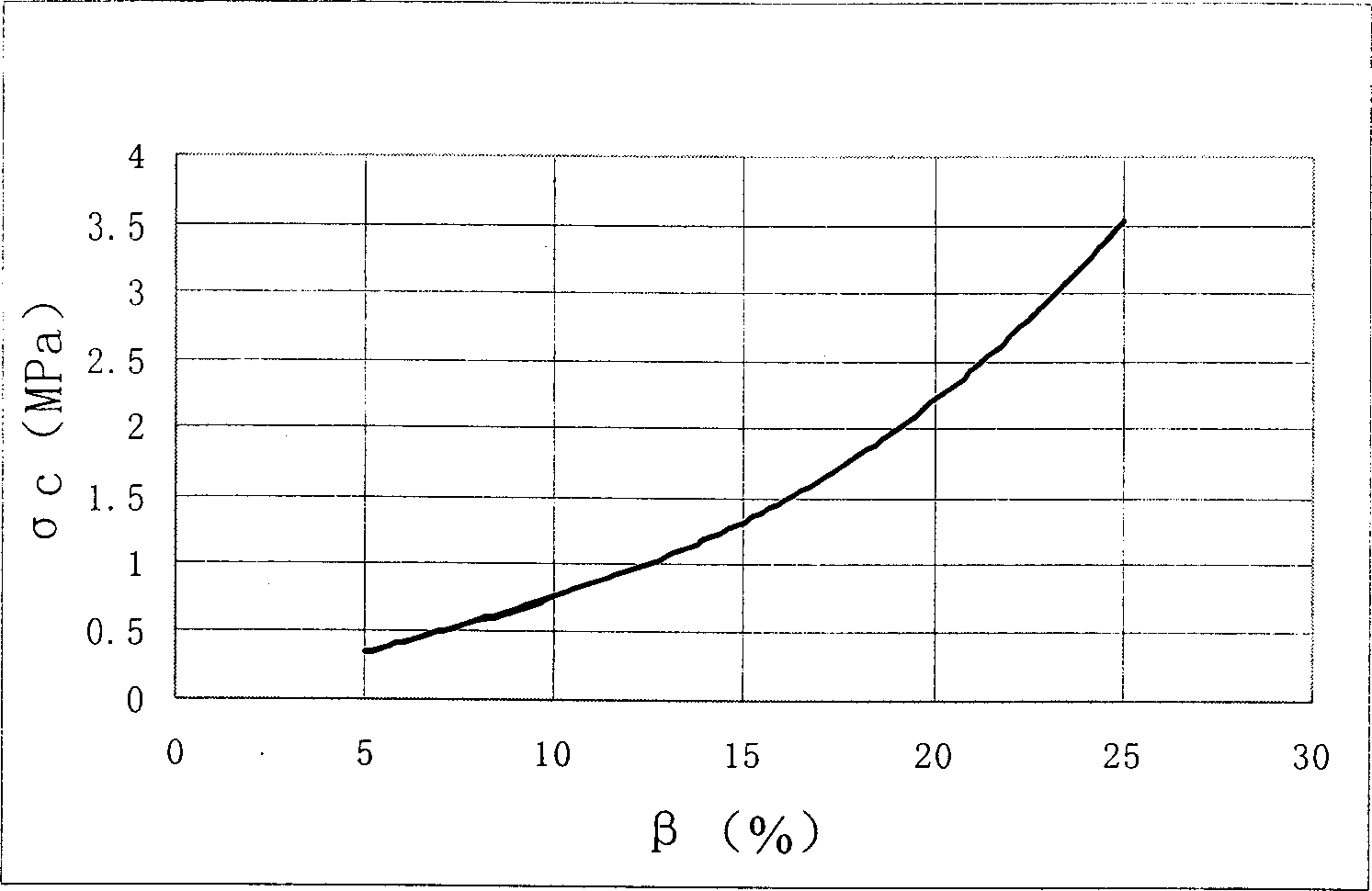

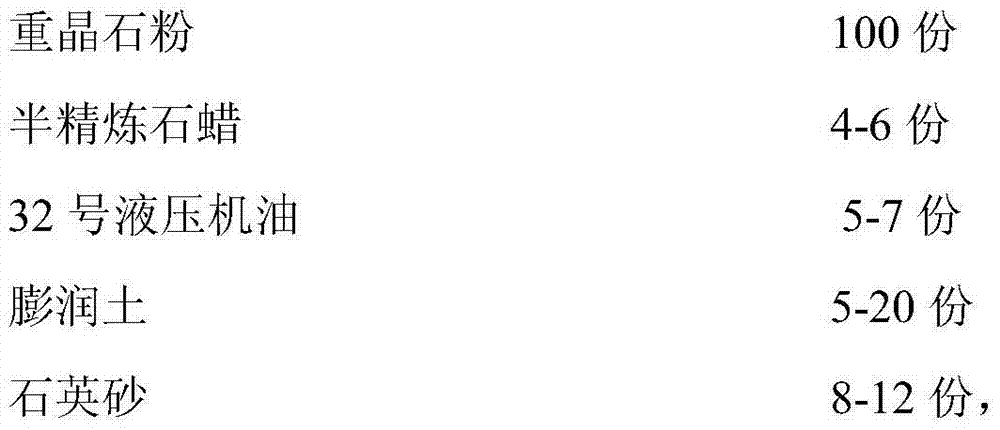

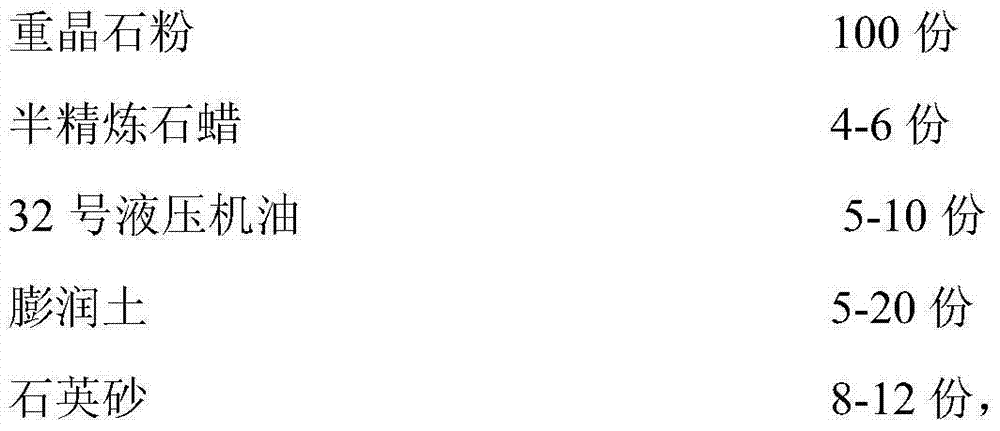

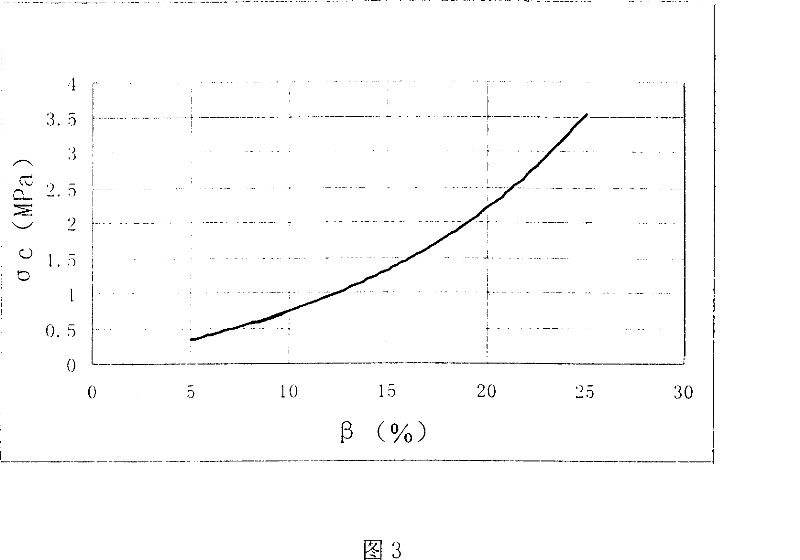

Geomechanical model similar material for simulating cover layer and preparation method thereof

InactiveCN104119061ALight weightReduced compressive strengthPreparing sample for investigationClaywaresParaffin waxSide effect

The invention discloses a geomechanical model test similar material for simulating a cover layer, which is formed by mixing the following components in parts by mass: 100 parts of barite powder, 4-6 parts of semi-refined paraffin wax, 5-10 parts of 32# hydraulic machine oil, 5-20 parts of bentonite and 8-12 parts of quartz sand. After the material is prepared into a sample of which the volume weight is 16-22 KN / m<3> and the size is 10cm*10cm*10cm, the deformation modulus is 0.11-1.19 MPa, and the compression strength is 1.8-18.4 KPa. The invention also discloses a preparation method of the material. The compression strength and deformation modulus of the cover layer simulating material are lower, and the volume weight, compression strength and deformation modulus of the obtained material can change within a wide range by adjusting the amounts of the substances; and thus, the material can be used as an ideal geomechanical model similar material for simulating a cover layer. The geomechanical model test similar material fills up the blank in the prior art; the raw materials have wide sources and have no toxic or side effect; and the method has the advantages of simple preparation process, low energy consumption, high preparation efficiency and low cost.

Owner:SICHUAN UNIV

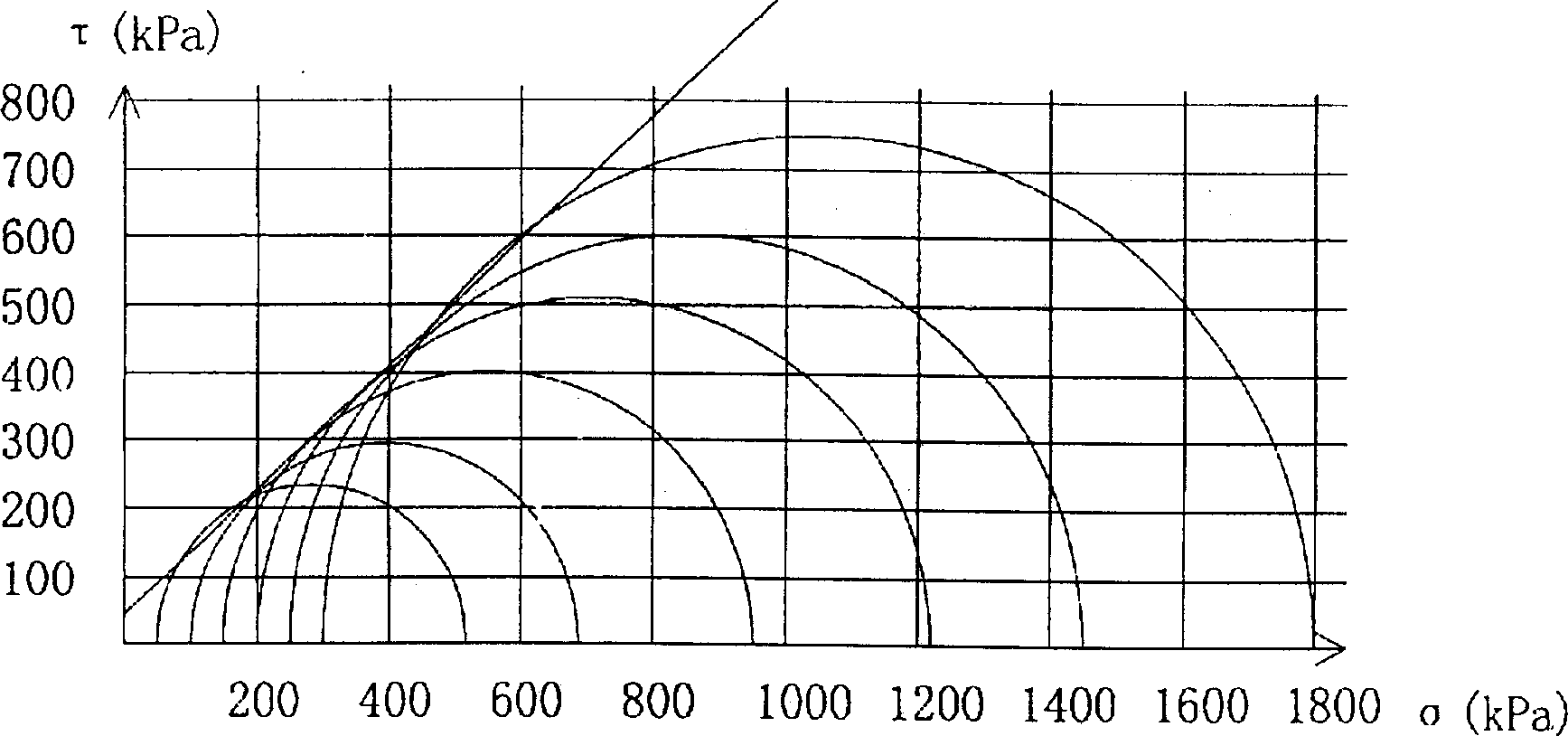

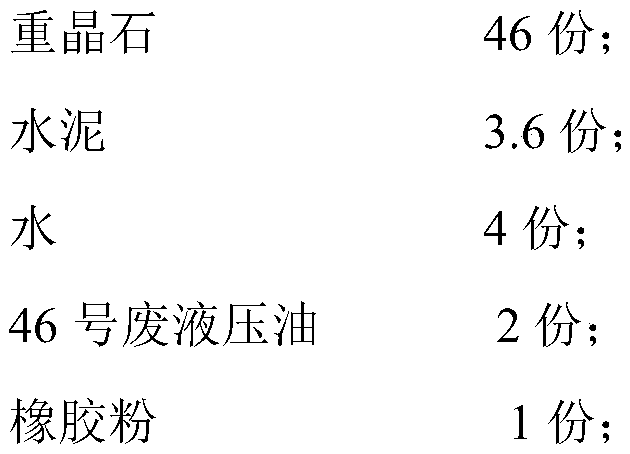

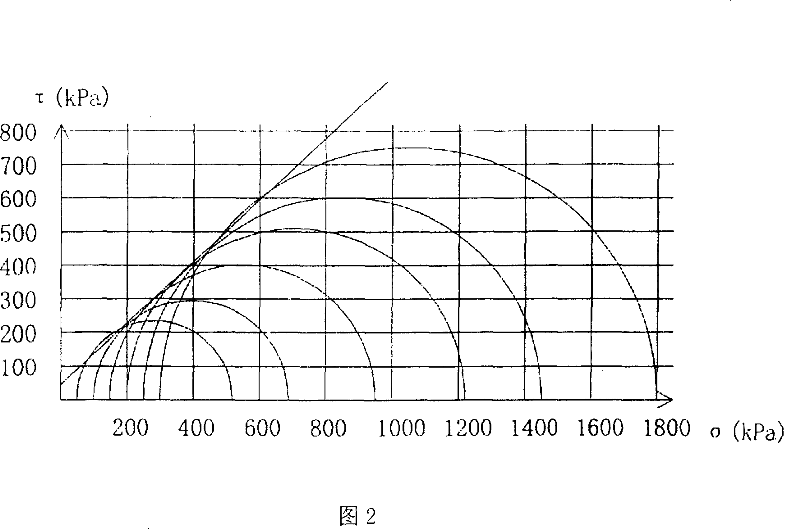

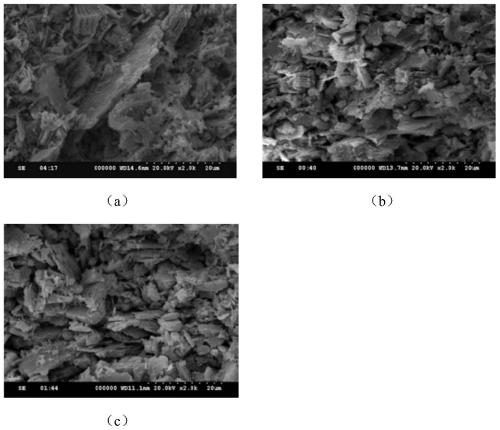

Rock similar material for geomechanics physical model test and preparation method thereof

The invention relates to the field of geological research, in particular to a rock similar material for a geomechanics physical model test and a preparation method thereof. The material is prepared from, by weight, 45-50 parts of barite, 1.5-3.9 parts of cement, 2.4-4.5 parts of water, 1-5 parts of 46# waste hydraulic oil and 0.5-1.5 parts of rubber powder. The barite and the rubber powder are evenly mixed, and then dried and dewatered, the mixture is taken out and cooled to room temperature, the cement is added to continue to be stirred to be uniform, the 46# waste hydraulic oil is added to the mixture to be stirred to be uniform, then the water is added to be stirred to be uniform, and the material is obtained. The preparation process of the method is simple, mixing is carried out at normal temperature in the preparation process, and therefore energy consumption is low, preparation efficiency is high, and cost is low.

Owner:CHINA THREE GORGES UNIV

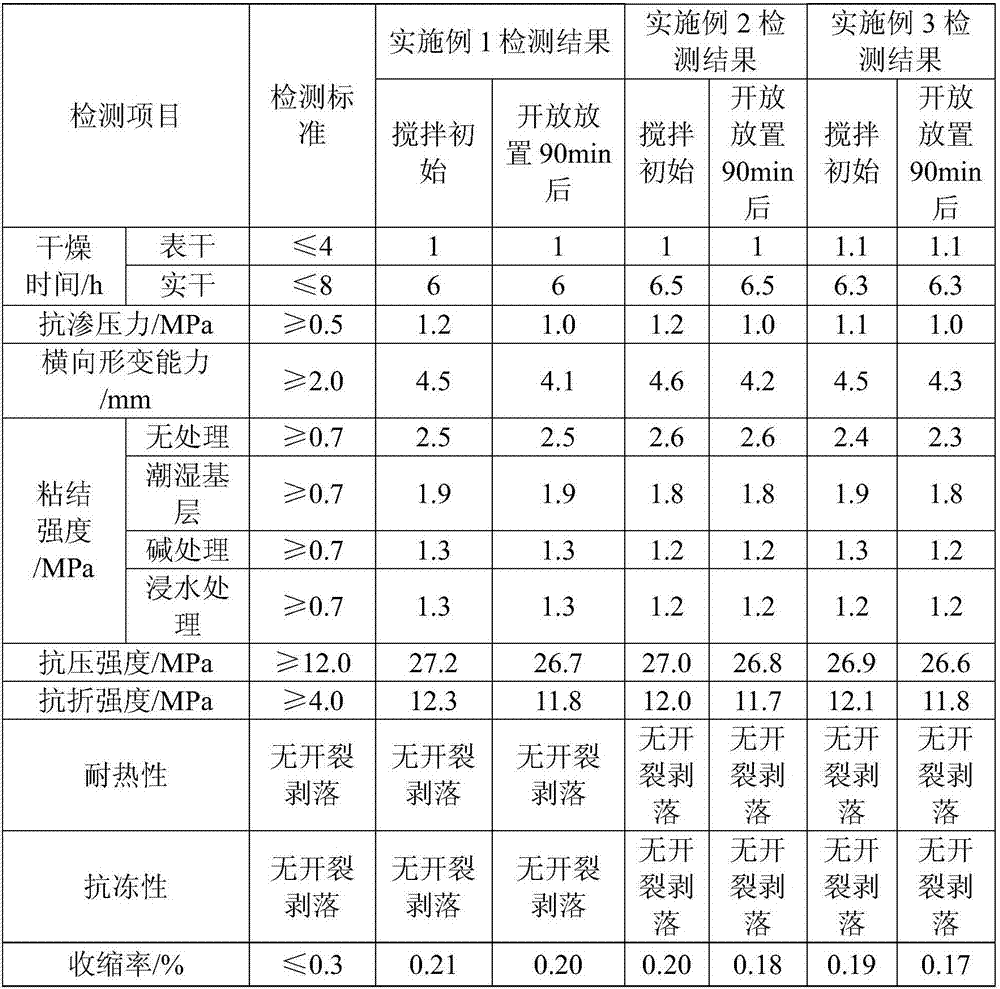

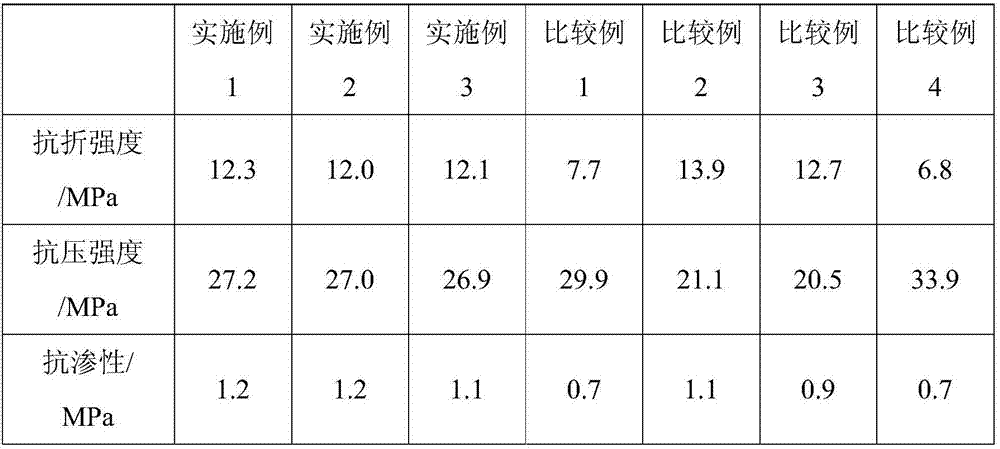

Environment-friendly polymer cement wall waterproof slurry and preparation method thereof

The invention provides environment-friendly polymer cement wall waterproof slurry and a preparation method thereof. The slurry comprises a liquid material and a powder material, wherein the mass ratio of the liquid material to the powder material is 1:(3-5); the power material comprises, by weight, 35-40 parts of cement, 35-40 parts of quartz sand, 20-25 parts of ground calcium carbonate, 0.1-0.3 part of lubricating agent and 0.2-0.5 part of water reducing agent; the liquid material comprises, by weight, 0.4-0.6 part of dispersing agent, 44-50 parts of water, 0.2-0.4 part of defoaming agent and 45-55 parts of polymer emulsion, the polymer emulsion comprises pure an acrylic emulsion and a styrene-acrylic emulsion, and the mass ratio of the acrylic emulsion to the styrene-acrylic emulsion is 1:(3-5). The slurry and the preparation method thereof have the advantages that the materials used by the slurry use water as the medium, so that the slurry is a waterborne product; the preparation method is green in process, low in energy consumption and free of environment pollution, does not generate three wastes and satisfies the requirements of environment protection.

Owner:台州中峰建筑材料有限公司

Similar material for simulating rock mass and preparation method thereof

The invention relates to a rock mass simulating material and a preparation method thereof. The rock mass simulating material is prepared from barite powder, cement, water, 32# hydraulic machine oil and polymer with a special formula I. The similar material has sensibility, can directly obtain deformation information of a model test, does not need an additional test apparatus, is greatly convenientfor test work in the test, can be used for simulating the rock mass similar material, is easy to process, does not need to maintain, can realize repeated utilization, and greatly reduce test cost.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

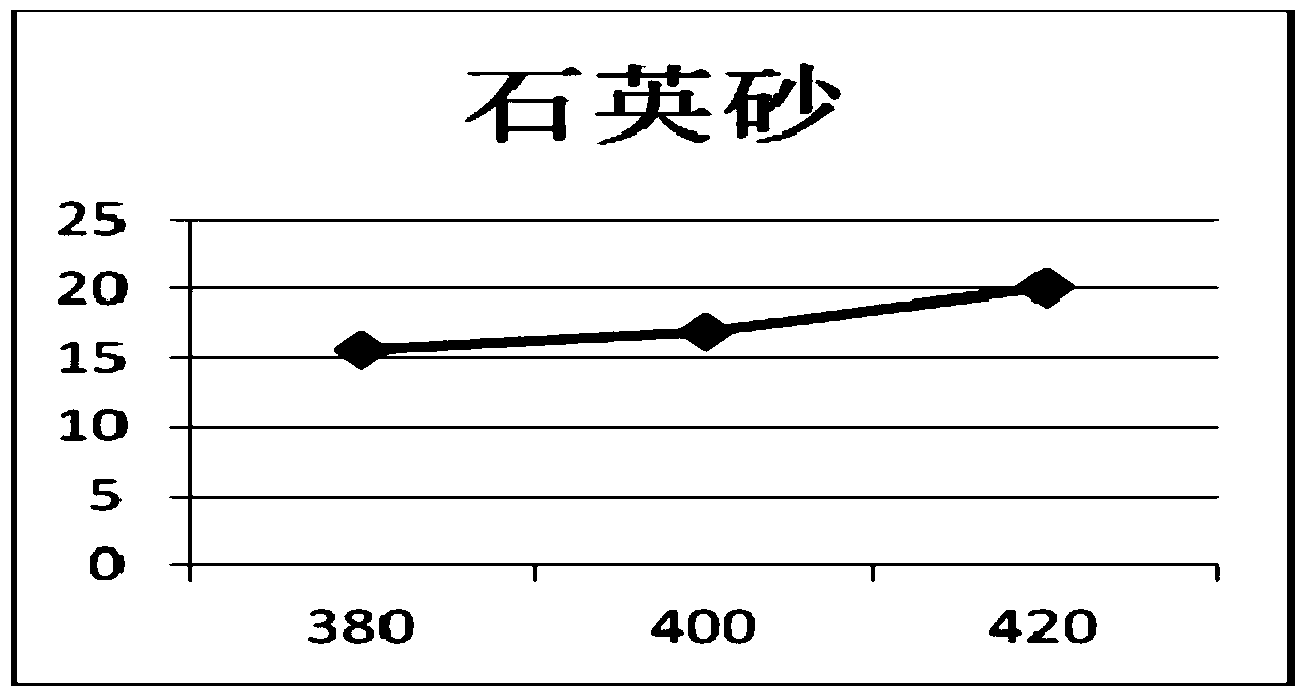

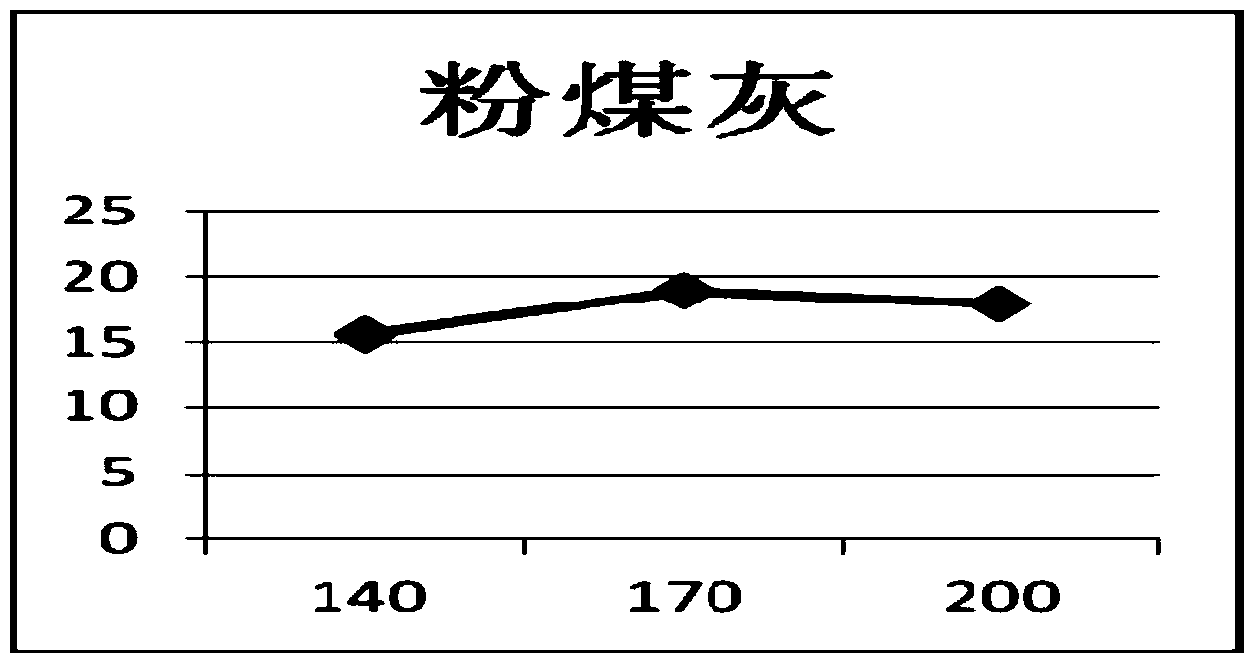

Geomechanical model similar material for simulating V-class surrounding rock

ActiveCN103936330AGood chemical stabilityGood stickinessSolid waste managementEnergy consumptionQuartz

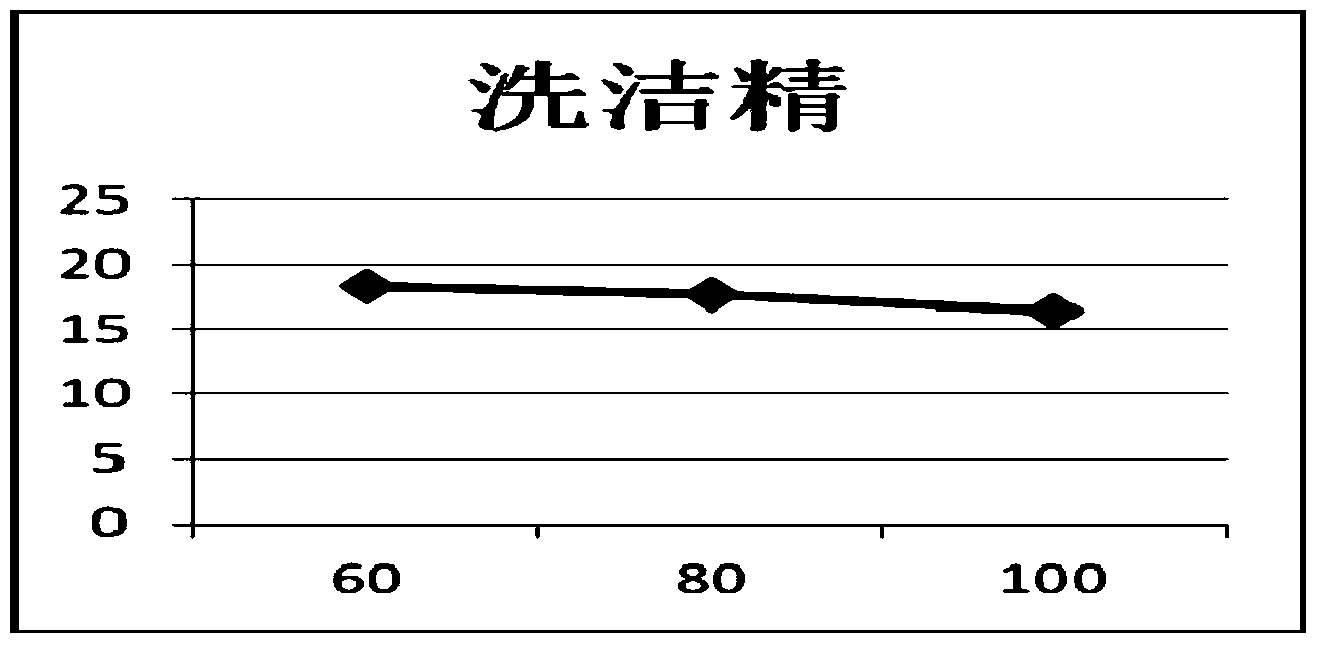

The invention discloses a geomechanical model similar material for simulating V-class surrounding rock, and belongs to the field of engineering similar simulation materials. The similar material is formed by mixing the following components in parts by weight: 380-430 parts of quartz sand, 140-200 parts of fly ash and 60-100 parts of liquid detergent, wherein cohesion measured is 0.476-17.774MPa and an internal friction angle is 13.393-22.264 degrees. Furthermore, the invention discloses influence of the quartz sand, the fly ash and the liquid detergent on the cohesion and the internal friction angle, so as to facilitate a rock mass to simulate required V-class surrounding rock materials differing in performance through regulating mixing amounts conveniently; moreover, the material is simple in preparation process, stable in performance, low in energy consumption, high in efficiency, low in cost, clean and harmless to humans.

Owner:BEIJING UNIV OF TECH

Sandstone similar material based on freeze-thaw cycle model tests and preparation method thereof

InactiveCN110294617AMeet porosityMeet frost resistancePreparing sample for investigationCeramicwareFreezing thawingDistilled water

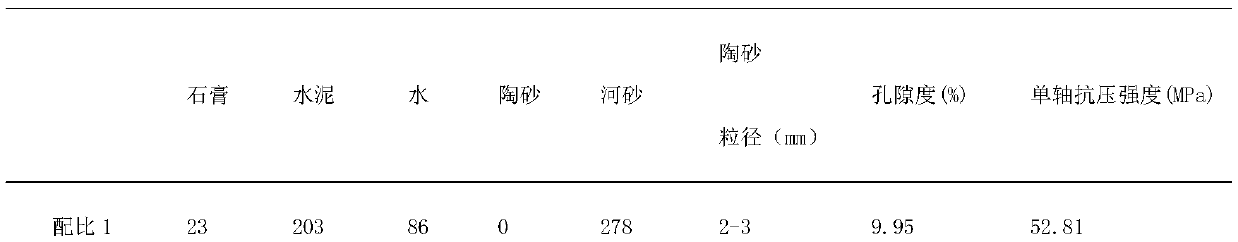

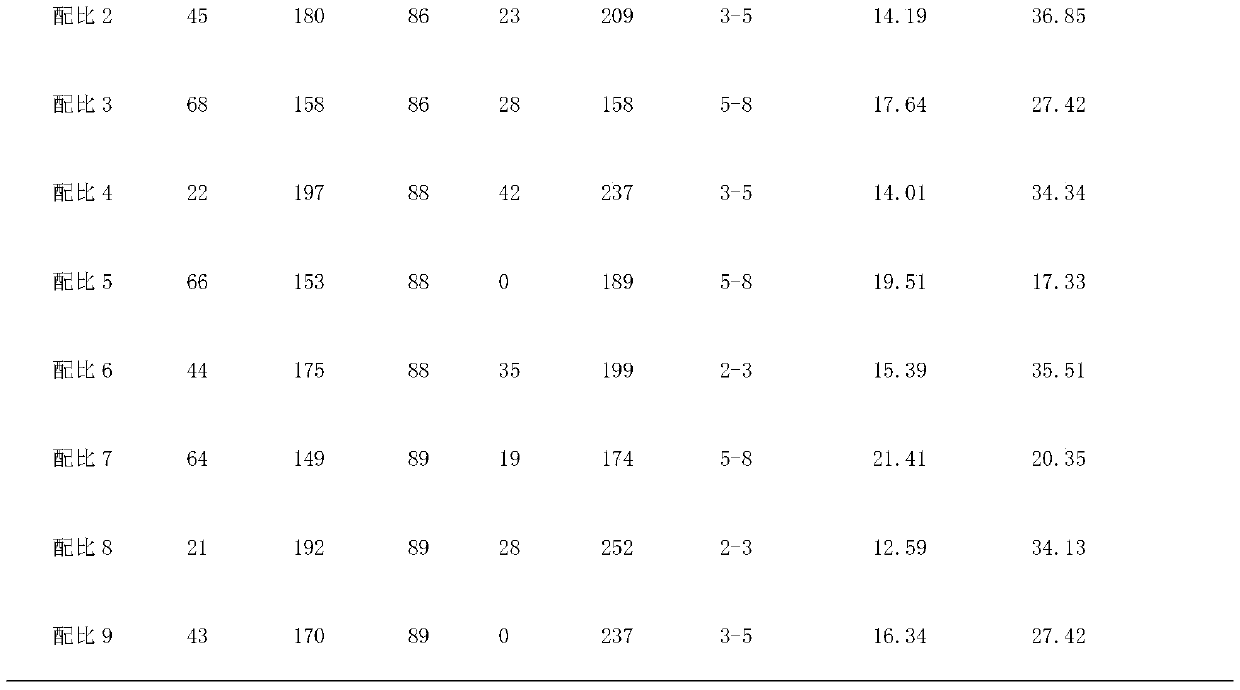

The invention relates to a sandstone similar material based on freeze-thaw cycle model tests and a preparation method thereof. The sandstone similar material comprises, by weight, 186-280 parts of anaggregate, 213-225 parts of a bonding agent and 86-89 parts of water; the aggregate comprises, by weight, 158-278 parts of standard river sand, 0-35 parts of 40-80 mesh pottery sand, 0-42 parts of 32-40 mesh pottery sand, and 0-28 parts of 20-32 mesh pottery sand; the bonding agent adopted in the aggregate is prepared by mixing 21-68 parts of plaster and 149-203 parts of cement. The preparation method of the sandstone similar material includes the step that according to the proportion, the cement, the plaster, the river sand and the distilled water are weighed and then placed into a containerto be evenly stirred. By adopting the sandstone similar material, freezing resistance of sandstone can be well simulated; according to the sandstone similar material, a mixture of the plaster and thecement serves as the bonding agent; the mixture of the plaster and the cement has the advantages of having high bonding capability, stable properties, a high adjustable degree and the like, after themixture of the plaster and the cement serves as the bonding agent to be mixed with the aggregate, the similar material which is compact, uniform and stable in physical and mechanical property is obtained, and thus properties of the similar material coincide with those of sandstone.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Model test foundation soil and preparation method thereof

InactiveCN104215487AShort time spentShorten test timePreparing sample for investigationTested timeEngineering

The invention relates to model test foundation soil and a preparation method thereof, and belongs to the field of building and civil engineering. The model test foundation soil consists of powdered bentonite and glycerinum. The preparation method comprises the following steps of determining a mass ratio of bentonite to glycerinum needed by a model test through vane shear tests, uniformly and adequately mixing the bentonite and the glycerinum by utilizing a kneading civil engineering stirrer according to the acquired mass ratio so as to obtain a mixture, compacting the mixture by utilizing a drop hammer, and enabling the glycerinum to be adequately filled in gaps among bentonite particles. The foundation soil not only has the physical and mechanical properties similar to naturally formed soil, but also relatively stable in character; compared with the naturally formed soil, when the foundation soil achieves the steady non-water-discharging shear strength, the consumed time is relatively short, and the test time is reduced; the foundation soil does not need to be solidified in the test, has no volatility and can be reused, the waste of test materials can be avoided, the strength of the foundation soil before and after the model test is slightly varied, and the problem that the strength is improved due to excessively fast water discharging in the model test process can be avoided. The production process is simple, the simplicity and the easiness in implementation can be achieved, and the applicability is wide.

Owner:TONGJI UNIV

Method for preparing laboratory grouting cement soil

InactiveCN107246989AImprove integrityHigh compressive strengthPreparing sample for investigationCement groutSieve

The invention discloses a method for preparing laboratory grouting cement soil. The cement grouting soil is composed of soil, cement and water. The preparation method comprises the following steps: airing and breaking soil, passing through a 2mm sieve, and preparing wet soil according to the natural moisture content of 25%; infiltrating the prepared soil in a sealed vessel overnight; blending cement accounting for 20% of the mass of the wet soil into cement paste according to a water cement ratio of 0.5, and pouring a mixture of the wet soil and the cement paste into a stirrer for stirring; weighing multiple parts of the mixture based on the weight of 825g per part; placing each part of the cement in a cylindrical mold with the diameter of 70mm and the height of 200mm, and compacting for 50 times by using a compacting hammer. The finally prepared test block is the cylinder with the diameter of 70mm and the height of 100mm, test block materials can be placed in the mold at a time, the cement soil test block with high integrity is formed due to one-time compaction, the integrity of the cement soil test block is enhanced, the quantity of fault fissures is reduced, and the compressive strength of the cement soil is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Nanometer copper oxide in-situ reduction wood composite material and preparation method thereof

ActiveCN109176773AEasy to prepareHigh activityWood treatment detailsCane mechanical workingFiberThermal compression

The invention discloses a nanometer copper oxide in-situ reduction wood composite material and a preparation method thereof. The nanometer copper oxide in-situ reduction wood composite material is made of five components, and the components include, by mass, 40%-50% of Chinese pennisetum micro powder, 20%-30% of wheat straw middlings, 10%-20% of reed fiber, 10%-15% of nanometer copper oxide powderand 0.5%-3% of polyethylene glycol 400. The preparation method comprises eight steps including preparation of the Chinese pennisetum micro powder, preparation of the wheat straw middlings, preparation of the reed fiber, matching, preparation of wood alloy, material mixing, thermal compression moulding forming and subzero treatment. According to the preparation method, material forming theories ofthe interdisciplines including powder metallurgy and powder engineering, composite material and engineering, wood science and technology and the like are comprehensively applied, and the wood composite material forming technology and method are innovated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method of degradable straw fiber foam material

The invention discloses a preparation method of a degradable straw fiber foam material and belongs to the technical field of preparation of composite materials. The method comprises the steps as follows: alkalization and modification of straw, preparation of a polyvinyl chloride mixture and formation of the degradable straw fiber foam material. The prepared degradable straw fiber foam material has good physical and mechanical performance, high chemical stability and high strength and is environment-friendly and degradable, the straw serving as the main material comes from reutilized waste, polyvinyl chloride serving as the other main material can be obtained through recycling, the resource can be saved, and the production cost is lower than that of a traditional plastic foam material.

Owner:HEFEI CHUANGWO TECH CO LTD

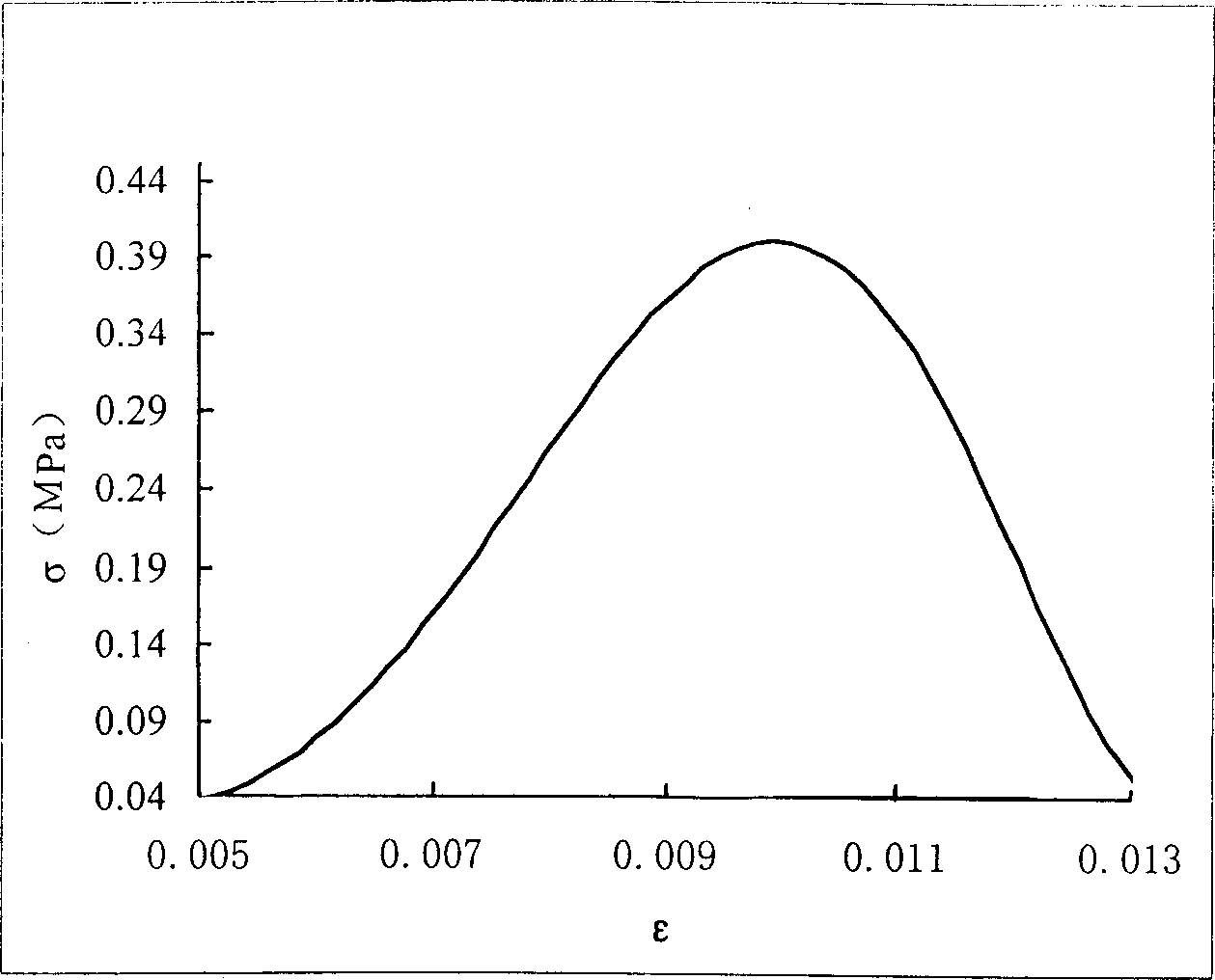

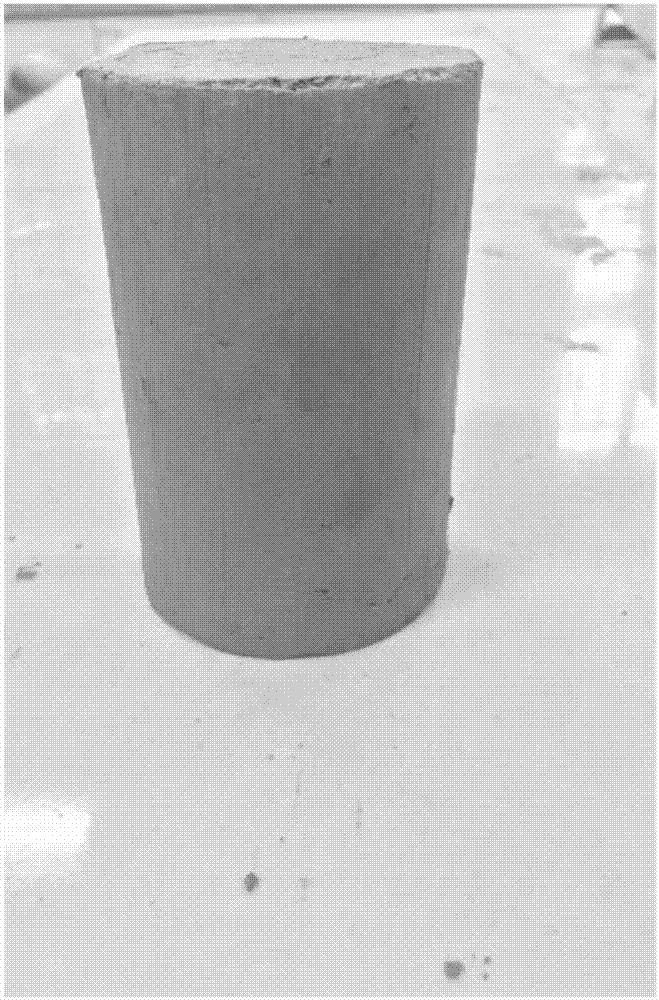

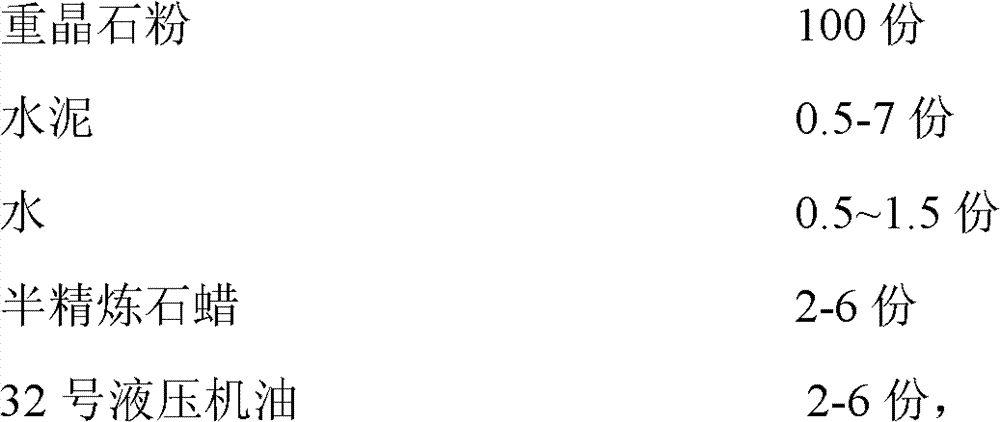

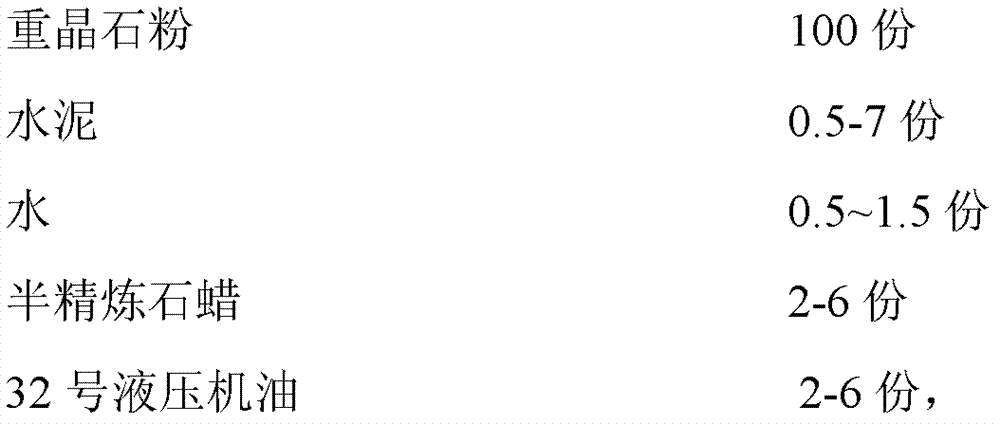

Geomechanical model simulating material for simulating rock mass and preparation method thereof

The invention discloses a geomechanical model simulating material for simulating a rock mass, which is formed by mixing the following components in parts by mass: 100 parts of barite powder, 0.5 to 7 parts of cement, 0.5 to 1.5 parts of water, 2 to 6 parts of semi-refined paraffin wax, and 2 to 6 parts of No.32 hydraulic engine oil; through testing, a test sample with the volume weight of 28KN / m<3> and size of 10cm*10cm*10cm, which is made of the material, has the deformation modulus of between 29.5 and 109.1MPa and the tensile strength of between 0.33 and 1.21MPa; and through a test sample with the volume weight of 24KN / m<3> and size of 10cm*10cm*5cm, which is made of the material, has the deformation modulus of between 26.4 and 94.7MPa and the tensile strength of between 0.30 and 1.02MPa. The invention also discloses a preparation method of the material. The rock mass simulating material provided by the invention contains the cement, the water, the paraffin wax and the hydraulic engine oil, so that the tensile strength and the deformation modulus of the rock mass simulating material can change in a larger range by regulating the respective mixing amount of the cement, the water, the paraffin wax and the hydraulic engine oil, and the requirement for simulating rock masses with different performances can be fulfilled; and the invention has the advantages of simple preparation process, low energy consumption, high efficiency and low cost.

Owner:SICHUAN UNIV

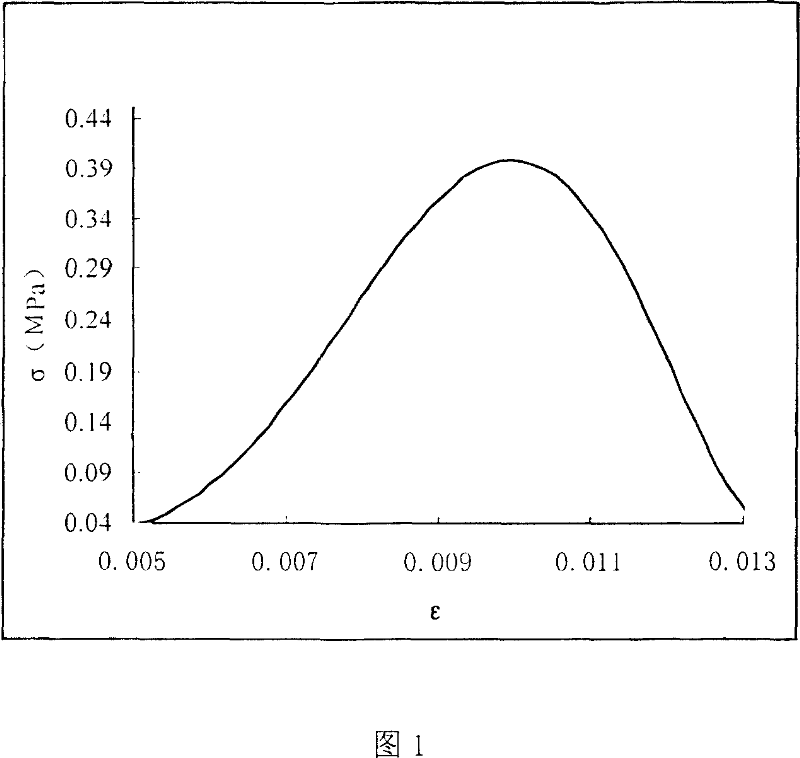

Geomechanics model simulating material for simulating weak rock mass and preparation method of geomechanics model simulating material

The invention discloses a geomechanics model simulating material for simulating a weak rock mass. The geomechanics model simulating material is composed of the following components in parts by mass: 100 parts of barite powder, 0.5-7 parts of semi-refined paraffin wax and 3-7 parts of No.32 hydraulic engine oil; the geomechanics model simulating material is prepared into a sample test with the volume weight of 26 kN / m<3> and the size of 10cm*10cm*10cm, the transformation modulus tested by the test sample is 13.2-28.3 MPa and the compressive strength tested by the test sample is 0.08-0.19 MPa; the geomechanics model simulating material is prepared into a test sample with the volume weight of 23 kN / m<3> and the size of 10cm*10cm*5cm, the transformation modulus tested by the test sample is 11.2-24.7 MPa and the compressive strength tested by the test sample is 0.07-0.17 MPa. The invention also discloses a preparation method of the geomechanics model simulating material. The compressive strength and the transformation modulus of the rock mass simulating material are lower so that the geomechanics model simulating material can be used as the more ideal geomechanics model simulating material for simulating the weak rock mass; and the geomechanics model simulating material provided by the invention has the advantages of wide source of the raw materials, no toxic side effects, simple preparation process, low energy consumption, high preparation efficiency and low cost.

Owner:SICHUAN UNIV

Method for manually preparing flocculent clay in coastal region

The invention discloses a method for manually preparing flocculent clay in a coastal region. The surface charge of kaolin particles is changed by chemical reagents, and the flocculent clay is preparedby the aid of a step-by-step loading prepressing technology. The method includes the steps: preparing dispersing agent solution, adding kaolin powder and mixing the dispersing agent solution and thekaolin powder to form slurry; adding flocculants and mixing the materials; applying load step by step to form a sample; performing step-by-step unloading according to the reverse order of load application; cutting and finishing the sample to finally obtain a flocculent clay sample. Compared with an existing method, the method has the advantages that a more loose and reliable flocculent structure can be acquired, and the flocculent clay with high water content in the coastal region can be more effectively simulated.

Owner:ZHEJIANG UNIV

A two-component room temperature non-curing asphalt polyurethane waterproof coating and its preparation method

ActiveCN110527424BImprove stabilityStable physicsPolyurea/polyurethane coatingsBituminous coatingsPolymer sciencePolyol

The invention discloses a two-component polyurethane asphalt waterproof coating and a preparation method thereof. Modified polyurethane prepolymer, polyurethane prepolymer is made by reacting polyol and polyisocyanate; B component contains petroleum asphalt, second hydroxyl terminal polybutadiene, secondary amine curing agent and / or primary amine curing agent; 1. The second hydroxyl-terminated polybutadiene is independently selected from one or more combinations of the compounds described in formula (I), and among the structural monomers in the formula, the monomer represented by a accounts for 10-30% , b accounts for 50-70%, and c accounts for 10-30%; preparation method: prepare components A and B separately and mix them; the present invention can not only realize the effect of non-curing at room temperature, but also has good coating stability and can always maintain Good dispersion uniformity ensures stable physical and mechanical properties of the coating.

Owner:JIANGSU CANLON BUILDING MATERIALS

Thermal insulation material for house building

InactiveCN108314362AStable physical and mechanical propertiesLow shrinkageHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a thermal insulation material for a house building. The thermal insulation material is prepared from the following ingredients in parts by weight: 40-57 parts of sand, 20-37 parts of pulverized fuel ash, 2-5 parts of heavy calcium powder, 0.1-0.2 part of hydroxypropyl methyl cellulose, 0.3-0.6 part of rubber powder, 0.15-0.3 part of wood fiber, 0.1-0.2 part of polypropylenefiber, 0.1-0.2 part of polyvinyl alcohol, 0.05-0.1 part of modified polyethylene oxide and 10-15 parts of water. According to the thermal insulation material, the physical and mechanical properties are stable, the shrinking percentage is low, the shrinkage crack can be resisted, meanwhile, the flame retardant property is good, and the heat conductivity coefficient is small.

Owner:浙江金宸建设有限公司

Retractable guniting wall protector and construction method thereof

InactiveCN101975071AAvoid breakingWith continuous bearing strengthUnderground chambersTunnel liningTunnel wallEngineering

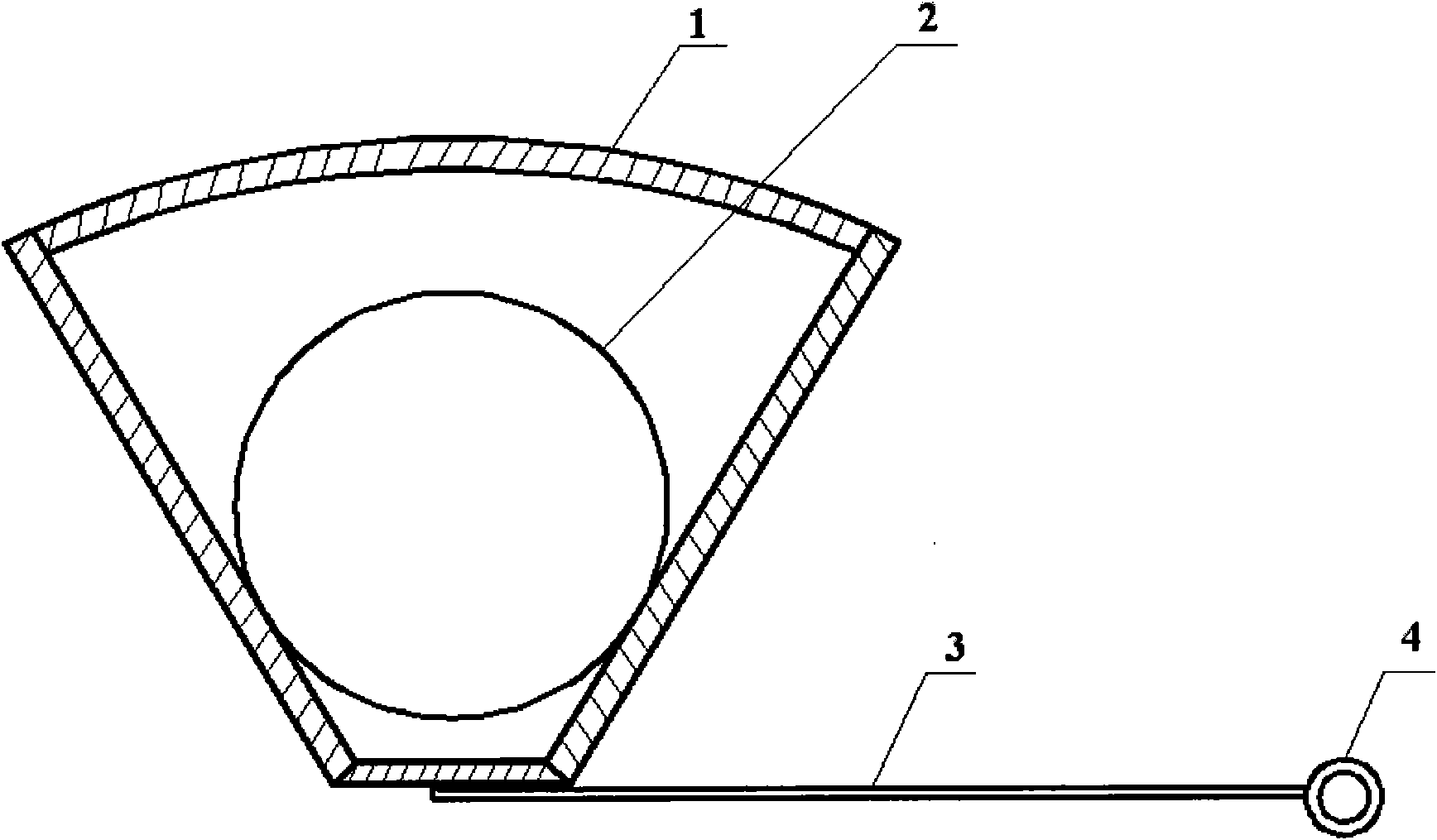

The invention discloses a retractable guniting wall protector and a construction method thereof. The retractable guniting wall protector is composed of a retractable device and a connecting device, wherein the retractable device is composed of an elastic tubular fan-shaped frame and an elastic annular tube; the fan-shaped frame is composed of a cambered baffle as the top surface and planar baffles as the rest of three surfaces; the height of the fan-shaped frame is suitable for the thickness of the guniting wall; the annular tube is welded in the fan-shaped frame; and in the connecting device, one end of a connecting rod is provided with a lantern ring, and the other end of the connecting rod is connected to the bottom frame opening of the fan-shaped frame. The construction method comprises the following steps: before guniting, installing the retractable guniting wall protector in the position which easily cracks, fixing with an anchor rod through the lantern ring, and guniting to embed the retractable device in the concrete. The retractable guniting wall protector has certain continuous bearing strength and strong deformability, and can sufficiently release tunnel wall deformation, thereby preventing the tunnel wall from rupture due to failure of deformation.

Owner:SHANDONG UNIV OF SCI & TECH

Iron spar powder, guartz sand cement rock-soil similar material and preparation process thereof

The invention relates to a method to produce equivalent material of iron crystal sand cemented rock soil that uses iron ore, barite powder and quartz sand as main aggregate, uses solution that is made up from rosin and alcohol as cementing agent, and uses gesso as regulator. Whisking the iron ore, barite powder and quartz sand, gesso, resin-alcohol solution to equal, pouring into steel mould, pressing the mixture, opening the mould, drying for 2-3 days, the invention could be gained. The invention has the advantages of high unit weight, large range of mechanics parameter, easy to process and low cost.

Owner:SHANDONG UNIV

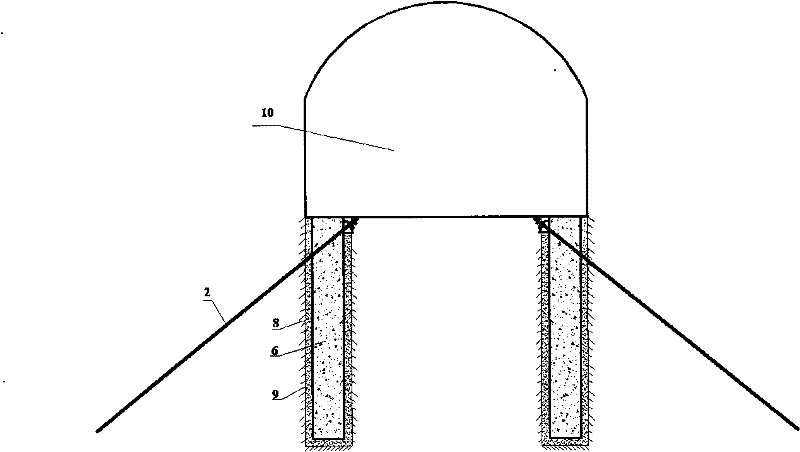

Soft rock roadway anchored concrete filled steel tube anti-floor heave device and construction method thereof

ActiveCN101975074BImprove skid resistanceImprove reinforcement effectBulkheads/pilesAnchoring boltsStress distributionCement mortar

The invention discloses a soft rock roadway anchored concrete filled steel tube anti-floor heave device and a construction method thereof. The construction method comprises the following steps: punching pile holes at the two sides of the floor of a roadway, embedding a steel tube body in the pile holes, pouring cement mortar, fixing the steel tube body in the pile holes, pouring concrete in the steel tube body to form a steel pipe pile, enabling an anchor rod or an anchor cable to penetrate the through holes of the steel tube pile and be anchored in rock formation at the two base angles of the roadway, sheathing cushion blocks, and fastening by nuts to form an anchoring structure. The invention can effectively control the roadway floor heave, improve stress distribution, and have the advantages of simple and convenient construction process, low cost, short time limit, superior cost performance, and stable physical mechanical properties.

Owner:滕州市产品质量监督检验所

A device for making soil/rock samples with different moisture content

ActiveCN105115796BReach moisture contentUniform moisture contentPreparing sample for investigationEngineeringAtmospheric pressure

A device for making soil samples / rock samples with different moisture content. The main box is a closed space. A bracket is installed in the middle of the main box. A weight detection device is installed on the bracket. The weight detection device is equipped with a weighing tray. The space inside the main box is divided into the space for placing soil samples / rock samples on the upper side and the humidification space on the lower side. There is a water tank in the humidification space of the main box, and a heating device is installed in the water tank. The main box is placed in the soil / rock sample The position of the space is provided with a box door for putting in and taking out the soil sample / rock sample, and an air pressure detection device, a temperature detection device and a humidity detection device are arranged on the top of the soil sample / rock sample storage space in the main box. The invention makes the water content state of the obtained soil sample / rock sample more uniform, the physical and mechanical properties of the soil sample / rock sample are stable and easy to control, the operation process is simple and convenient, and the preparation efficiency is high.

Owner:CENT SOUTH UNIV

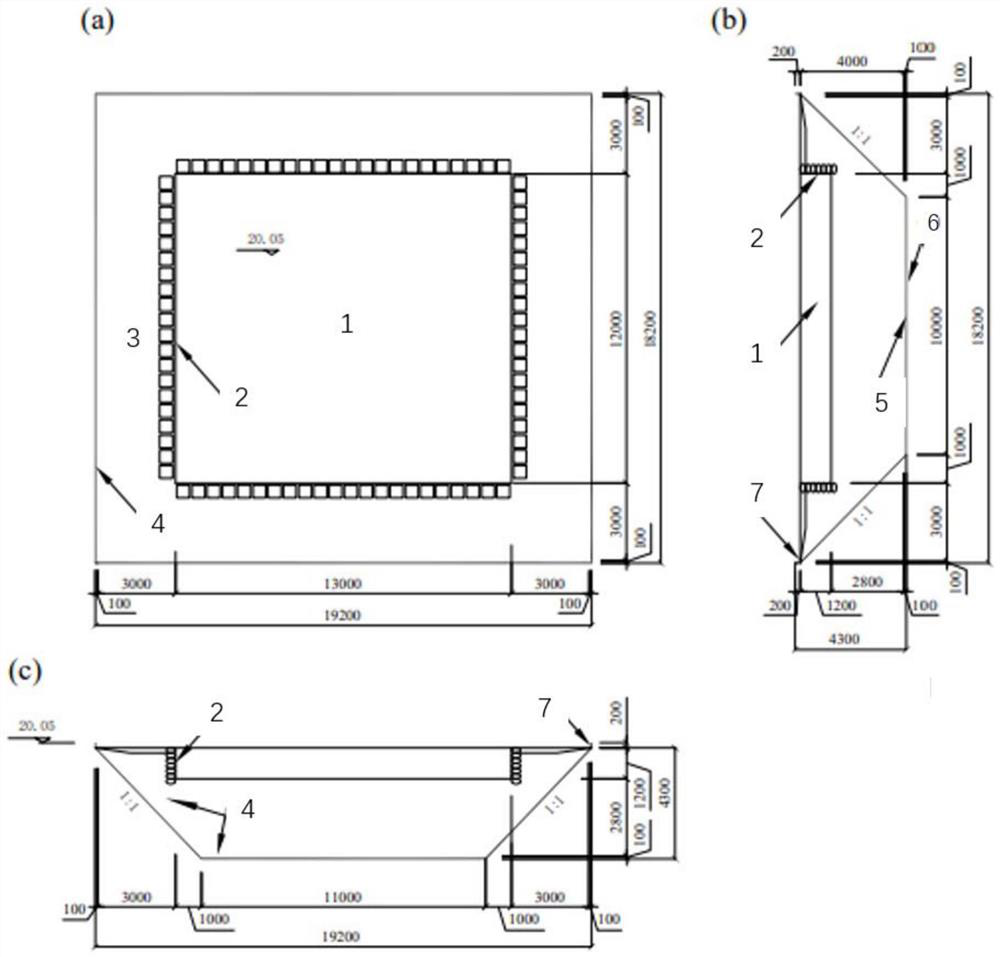

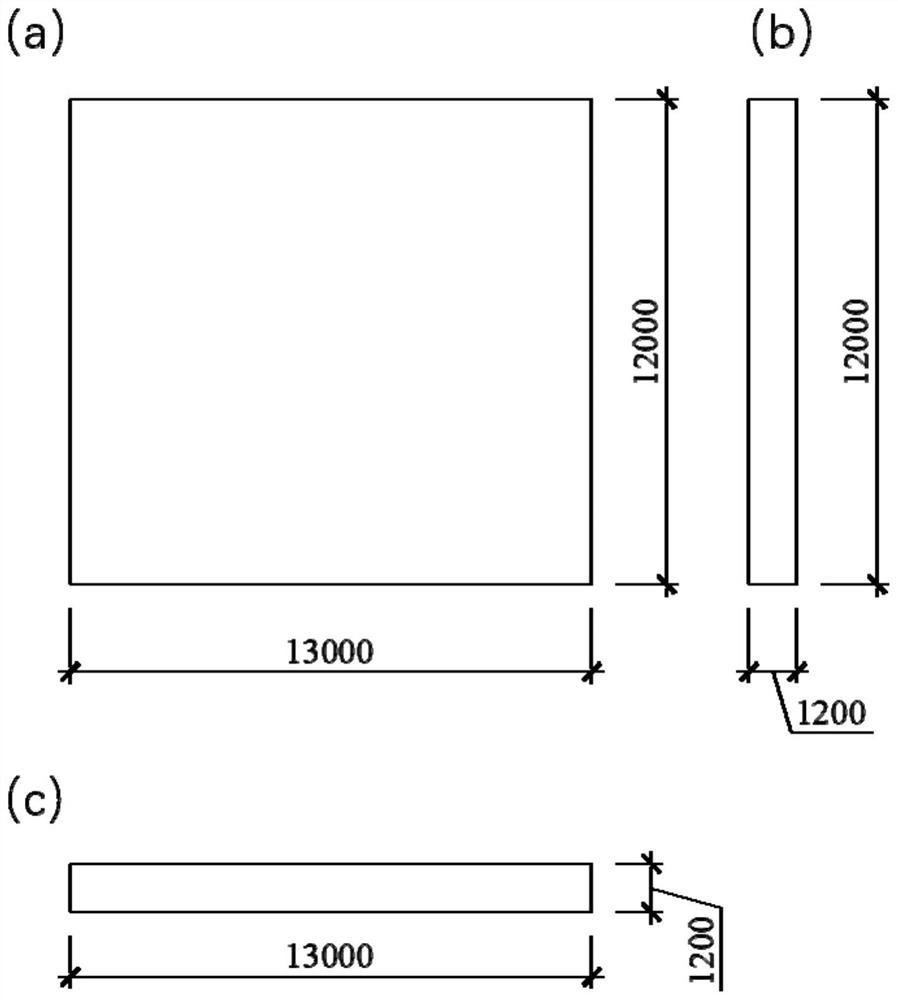

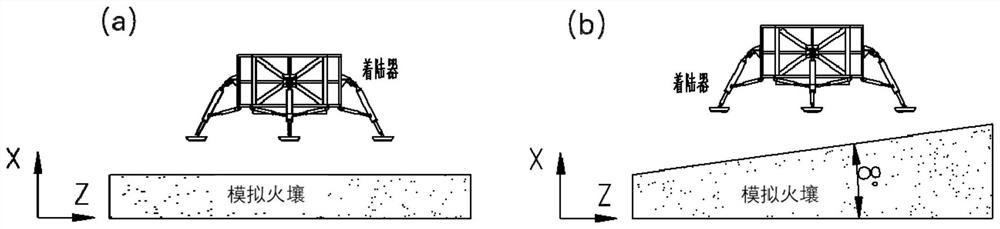

Simulated Mars soil preparation method and test bed construction method

PendingCN114495677AThe physical and mechanical properties remain stableWide range of usesEducational modelsMartian soilSoil science

The invention discloses a simulated Mars soil preparation method which comprises the following steps: sequentially drying, removing impurities and crushing volcanic ash to obtain volcanic ash particle aggregates with different particle size ranges, and obtaining corresponding simulated Mars soil standard gradation according to a preset soil mechanical property target value range. The simulated Mars soil can be produced in batches according to the standard grading; the invention further discloses a construction method of the simulated Mars soil test bed, the simulated Mars soil laying area is arranged in the foundation pit, layered filling of the simulated Mars soil is carried out to obtain the test bed, and after filling of each layer is completed, the physical and mechanical parameters of the test bed are controlled according to the physical and mechanical property requirements; a severe landing environment is built on the surface of the test bed. The Mars surface fire soil landform and physical and mechanical properties can be truly reproduced, it is ensured that the Mars lander can recognize the severe environment of the Mars surface with high precision in the Mars surface soft landing process, and meanwhile accidents such as foot pad subsidence are avoided.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

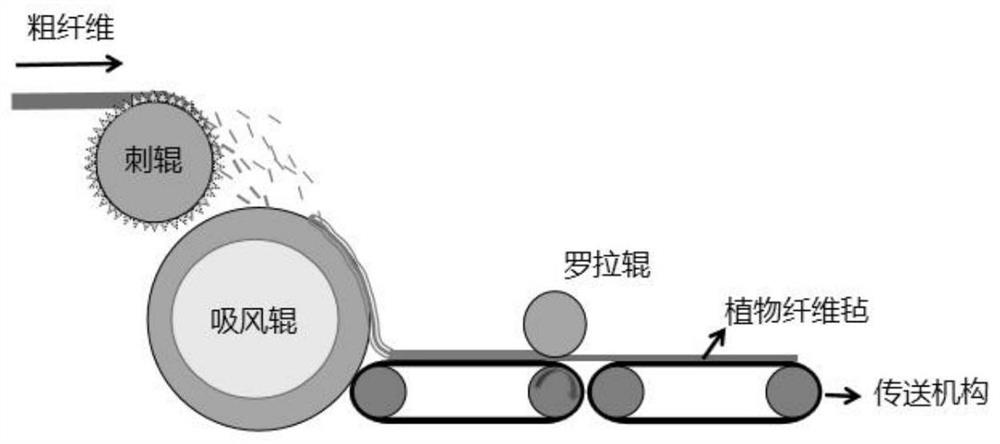

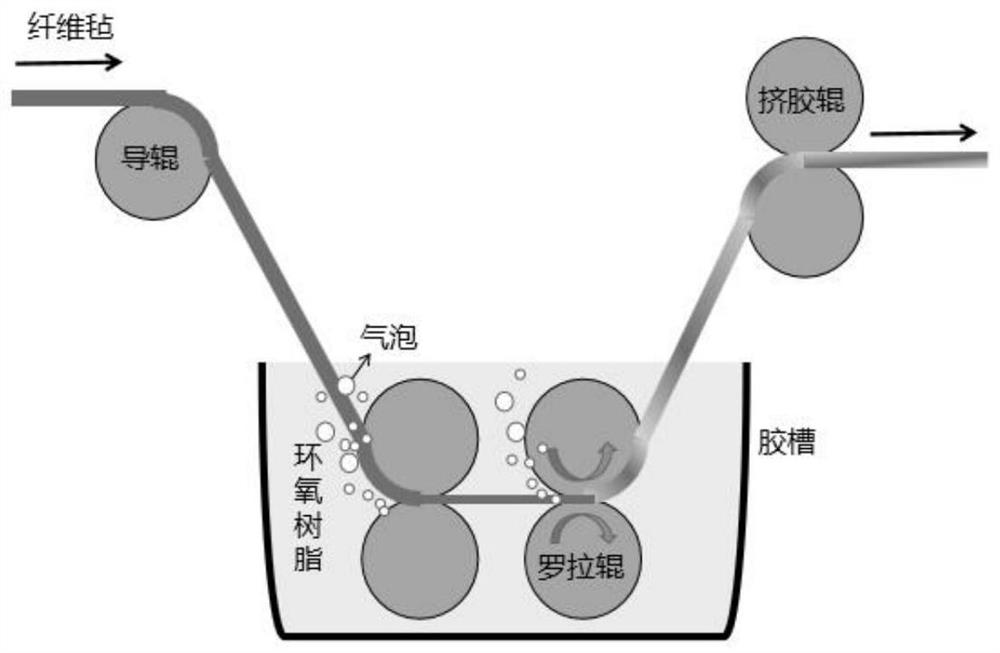

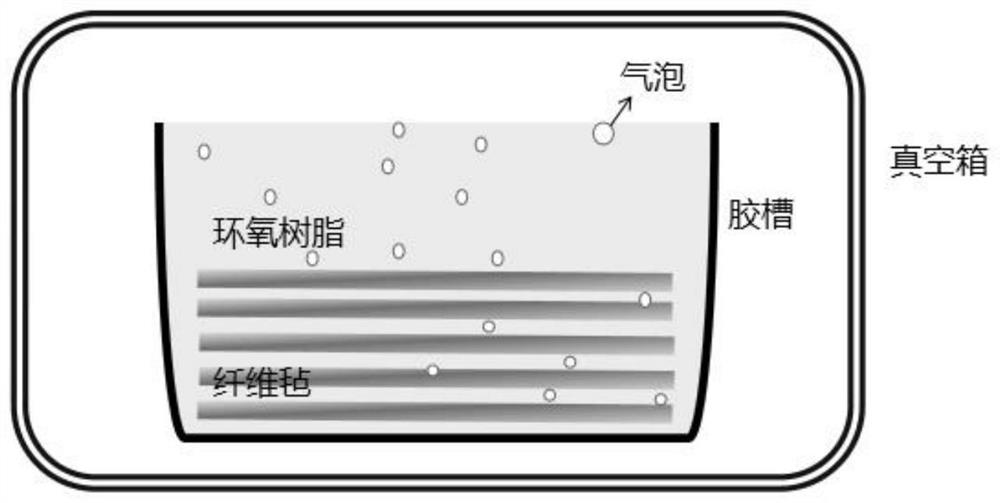

Thermosetting plant fiber prepreg as well as preparation method and application thereof

The invention provides a thermosetting plant fiber prepreg as well as a preparation method and application thereof, and relates to the technical field of prepregs. The preparation method of the thermosetting plant fiber prepreg comprises the following steps of placing a plant fiber reinforced phase in a thermosetting resin compound system, and carrying out roller impregnation or vacuum impregnation to obtain an impregnated plant fiber system; and carrying out hot-pressing pretreatment or cold-pressing pretreatment on the impregnated plant fiber system, and after the obtained system is shaped, carrying out laminating to obtain the thermosetting plant fiber prepreg. According to the prepreg, the method and the application, roller impregnation or vacuum impregnation is adopted for impregnation, so that the plant fibers can be fully in contact and infiltrated with a thermosetting resin compound system, the generation and movement of pores are controlled, and the resin content is controlled from the raw material preparation stage; and the interface property of the prepared thermosetting plant fiber prepreg is superior to that of a traditional plant fiber epoxy composite material, the storage life can be prolonged, and the physical and mechanical properties are more stable.

Owner:INT CENT FOR BAMBOO & RATTAN

A method for artificially preparing flocculated clay in coastal areas

ActiveCN108408733BQuality improvementImprove consistencySilicon compoundsPhysical chemistryKaolin clay

Owner:ZHEJIANG UNIV

A kind of nano-copper oxide in-situ reduction wood composite material and preparation method thereof

ActiveCN109176773BEasy to prepareHigh activityWood treatment detailsCane mechanical workingFiberPolyethylene glycol

The invention discloses a nano-copper oxide in-situ reduction wood composite material and a preparation method thereof. A nano-copper oxide in-situ reduction wood composite material is made of five components, and the components are: Pennisetum micropowder 40%-50%, wheat straw coarse powder 20%-30%, reed fiber 10%~20%, nano-copper oxide powder 10%~15%, polyethylene glycol-400 0.5%~3%. The preparation method comprises eight steps of preparation of Pennisetum micropowder, preparation of wheat straw coarse powder, preparation of reed fiber, batching, preparation of wood alloy powder, material mixing, hot molding and cryogenic treatment. The preparation method comprehensively applies powder metallurgy and powder engineering, composite materials and engineering, wood science and technology and other interdisciplinary material forming theories, and innovates the forming technology and method of wood composite materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com