Geomechanical model simulating material for simulating rock mass and preparation method thereof

A geomechanical, model-similar technology, applied in the field of geomechanical model test materials and preparation, can solve the problems of inability to meet simulation, unable to prepare similar materials, etc., to achieve no toxic side effects, stable physical and mechanical properties, and a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

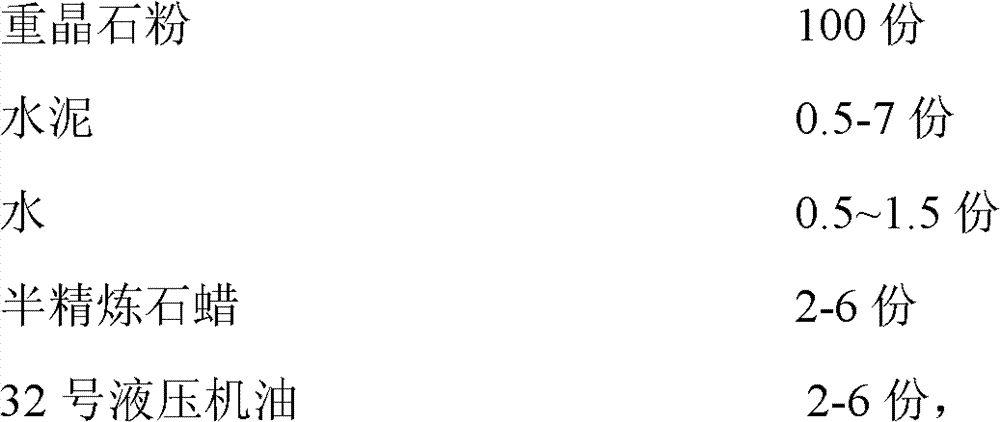

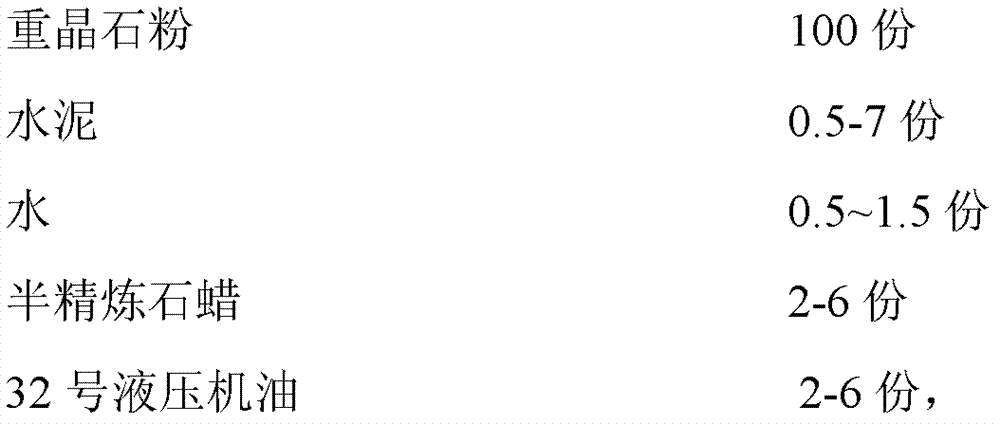

Embodiment 1

[0032] First mix 100 parts of barite powder with a particle size of 200 mesh and 4 parts of semi-refined paraffin wax with a melting point of 54°C, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 4 parts of No. 32 hydraulic oil Put it into the dried barite powder and semi-refined paraffin mixture and mix evenly, then crush the mixed material until its particle size is ≤1mm; add 7 parts of cement marked 425 to the barite powder, semi-refined paraffin and 32 No. hydraulic oil mixture, continue to mix evenly; finally add 1 part of water to the above mixture, and then mix evenly.

[0033] The material has a compressive strength of 1.17MPa and a modulus of deformation of 108.2MPa.

Embodiment 2

[0035]First mix 100 parts of barite powder with a particle size of 200 mesh and 2 parts of semi-refined paraffin wax with a melting point of 54°C, then bake at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 4 parts of No. 32 hydraulic oil Put it into the dried barite powder and semi-refined paraffin mixture and mix evenly, then crush the mixed material until its particle size is ≤1mm; add 1 part of cement marked 425 to the barite powder, semi-refined paraffin and 32 No. hydraulic oil mixture, continue to mix evenly; finally add 1.5 parts of water to the above mixture, and then mix evenly.

[0036] The material has a compressive strength of 0.33MPa and a modulus of deformation of 29.5MPa.

Embodiment 3

[0038] First mix 100 parts of barite powder with a particle size of 200 mesh and 6 parts of semi-refined paraffin wax with a melting point of 54°C, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 4 parts of No. 32 hydraulic oil Put it into the dried barite powder and semi-refined paraffin mixture and mix evenly, then crush the mixed material until its particle size is ≤1mm; add 1 part of cement marked 425 to the barite powder, semi-refined paraffin and 32 No. hydraulic oil mixture, continue to mix evenly; finally add 0.5 parts of water to the above mixture, and then mix evenly.

[0039] The material has a compressive strength of 0.79MPa and a modulus of deformation of 52.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com