Thermosetting plant fiber prepreg as well as preparation method and application thereof

A plant fiber and thermosetting technology, applied in the direction of coating, etc., can solve problems such as poor compatibility, bubble growth, poor motion controllability, and product performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of thermosetting plant fiber prepreg, comprising the following steps:

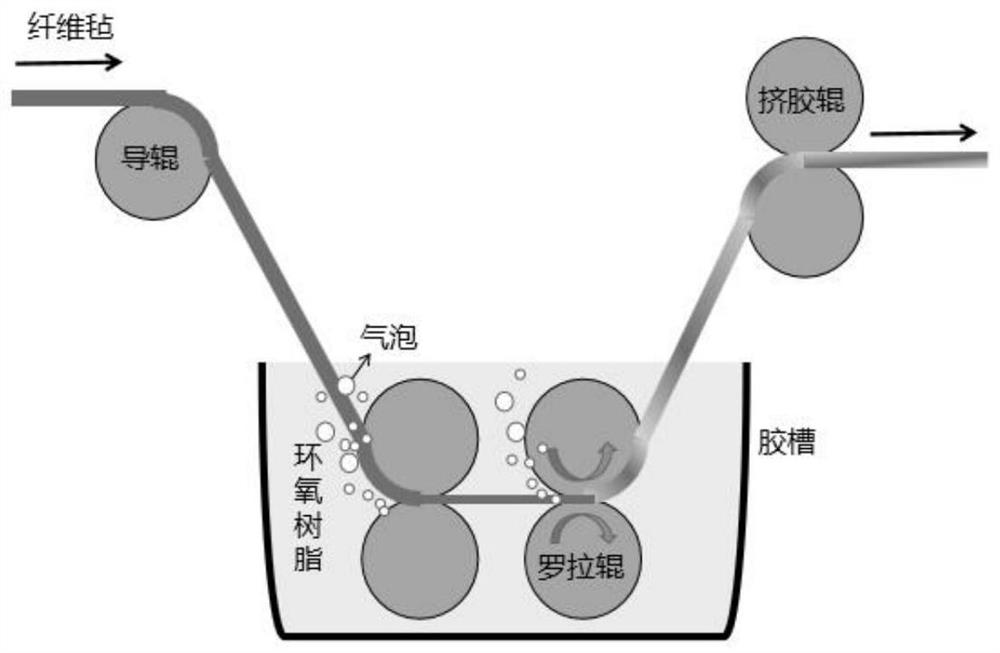

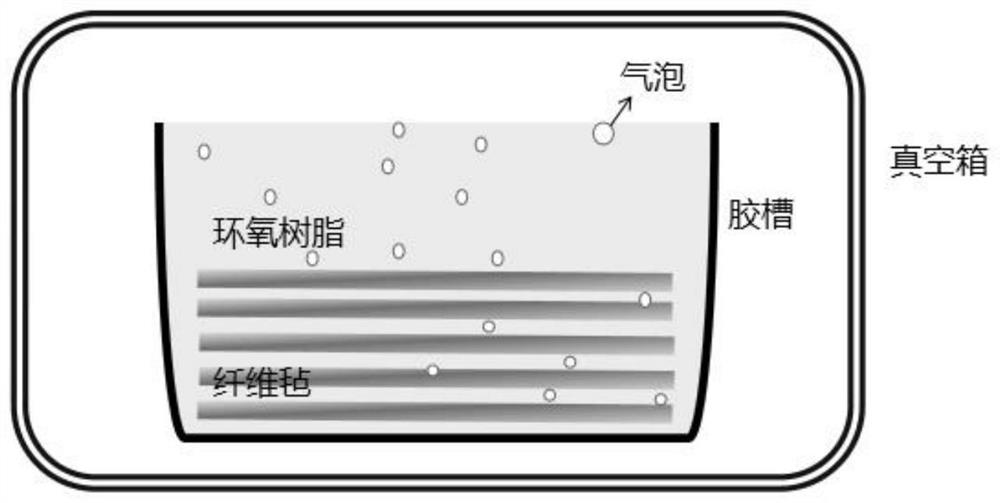

[0027] Place the plant fiber reinforcement phase in the thermosetting resin composite system, and carry out roller impregnation or vacuum impregnation to obtain the impregnated plant fiber system;

[0028] The impregnated plant fiber system is subjected to hot-press pretreatment or cold-press pretreatment, and after the obtained system is finalized, it is covered with a film to obtain a thermosetting plant fiber prepreg.

[0029] In the invention, the plant fiber reinforced phase is placed in a thermosetting resin composite system, and roller impregnation or vacuum impregnation is performed to obtain an impregnated fiber felt system. In the present invention, the plant fiber reinforced phase preferably includes plant fibers and a fixing layer arranged on one side of the plant fibers. In the present invention, the thickness ratio of the plant fiber...

Embodiment 1

[0058] Preparation of thermosetting resin compound system: Stir liquid epoxy resin E54 uniformly at a high speed at 200r / min, heat to 70°C, add curing agent methyltetrahydrophthalic anhydride and accelerator dimethylimidazole in sequence, the liquid ring The mass ratio of epoxy resin E54, methyltetrahydrophthalic anhydride and dimethylimidazole is 10:8:1, stir at high speed until the mixture is evenly mixed to obtain a thermosetting resin compound system, and pour it into the glue tank;

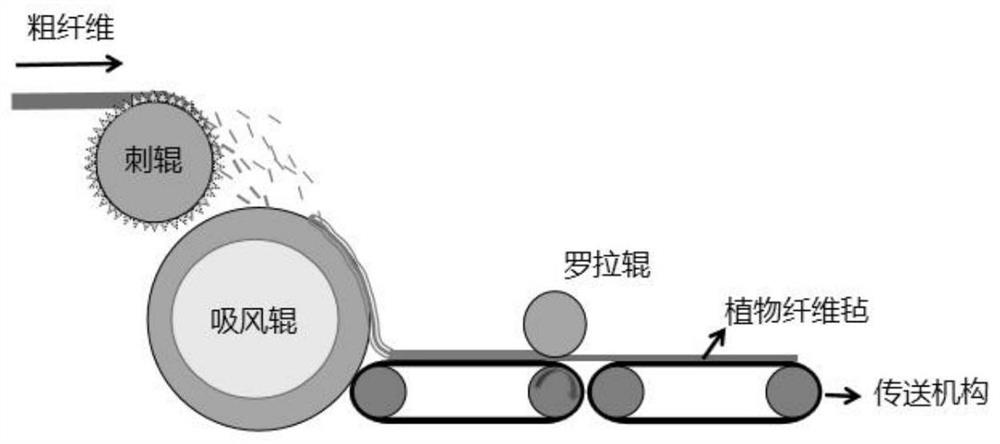

[0059] Preparation of continuous bamboo fiber felt: cut bamboo into slices, soak in water for 24 hours, perform mechanical rolling, fiber opening and drying in sequence to obtain crude fibers; perform combing, directional matting and roller thickness determination on the crude fibers in sequence , obtain continuous bamboo fiber felt; The feeding speed of described directional matting is 5m / min, and the fixed thickness of roller is 10mm, and the fixed width is 300mm;

[0060]Gel state bamboo f...

Embodiment 2

[0063] Preparation of thermosetting resin compound system: Stir liquid epoxy resin E52 evenly at high speed at 200r / min, heat to 50°C, add curing agent isophorone diamine, interface modifier KH550 and thickener flour in sequence , the mass ratio of the liquid epoxy resin E52, isophorone diamine, KH550 and flour is 4:1:0.1:0.5, stir at a high speed until the mixture is uniform, and obtain a thermosetting resin compound system, which is poured into the glue in the slot;

[0064] Preparation of bamboo yarn grid cloth: Weave 3 public bamboo fiber yarns, the weaving method is vertical and horizontal (〡-〡-〡), the grid size is 1mm×2mm, and the single-layer grid cloth has a fixed width of 300mm and a fixed width of 300mm. Long 300mm, obtaining the bamboo yarn grid cloth that the number of layers is 3 layers;

[0065] Gel state bamboo fiber grid cloth prepreg preparation (vacuum impregnation): one side of the bamboo yarn grid cloth is fixed on the thin-layer mesh felt to obtain a plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com