Geomechanical model similar material for simulating cover layer and preparation method thereof

A technology of geomechanics and similar materials, applied in the field of geomechanical model test of similar materials and their preparation, can solve problems such as inability to simulate similar, small deformation modulus, etc., achieve simple preparation process, good plasticity and cohesion, and a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

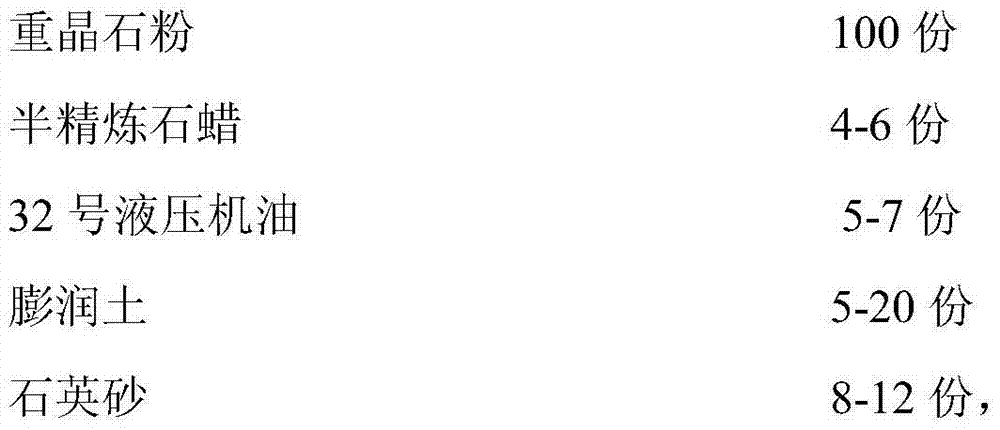

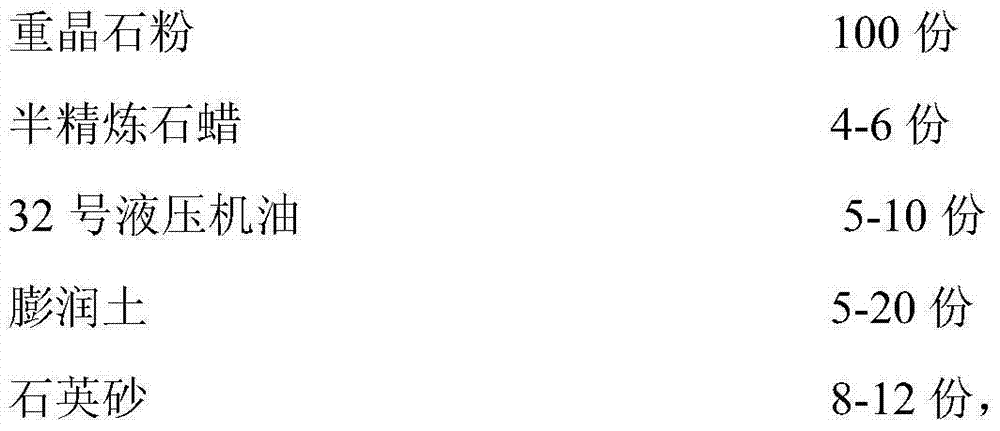

[0033]First mix 100 parts of barite powder with a particle size of 200 mesh and 4 parts of semi-refined paraffin wax at 54 degrees, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 5 parts of No. 32 hydraulic oil to the drying Mix well with the barite powder and semi-refined paraffin, and then crush the mixed material until its particle size is <1mm; add 5 parts of bentonite to the mixture of barite powder, paraffin and engine oil and mix evenly, then add 10 parts Ordinary quartz sand is added to the mixture and mixed evenly.

[0034] The deformation modulus of the material is 0.29MPa, and the compressive strength is 4.6KPa.

Embodiment 2

[0036] First mix 100 parts of barite powder with a particle size of 200 mesh and 5 parts of semi-refined paraffin wax at 54 degrees, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 5 parts of No. 32 hydraulic oil to the drying Mix well with the barite powder and semi-refined paraffin wax, and then crush the mixed material until the particle size is <1mm; add 15 parts of bentonite to the mixture of barite powder, paraffin and engine oil and mix evenly, then add 12 parts Ordinary quartz sand is added to the mixture and mixed evenly.

[0037] The deformation modulus of the material is 0.18MPa, and the compressive strength is 2.9KPa.

Embodiment 3

[0039] First mix 100 parts of barite powder with a particle size of 200 mesh and 4 parts of semi-refined paraffin wax at 54 degrees, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 7.5 parts of No. 32 hydraulic oil to the drying Mix well with the barite powder and semi-refined paraffin, and then crush the mixed material until its particle size is <1mm; add 5 parts of bentonite to the mixture of barite powder, paraffin and engine oil and mix evenly, then add 10 parts Ordinary quartz sand is added to the mixture and mixed evenly.

[0040] The deformation modulus of the material is 0.25MPa, and the compressive strength is 4.0KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com