Method for preparing laboratory grouting cement soil

A cement preparation and laboratory technology, applied in the field of civil engineering, can solve problems such as faults in cement-soil test blocks and weak interlayer bonding, and achieve the effect of enhancing compressive strength and stabilizing physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

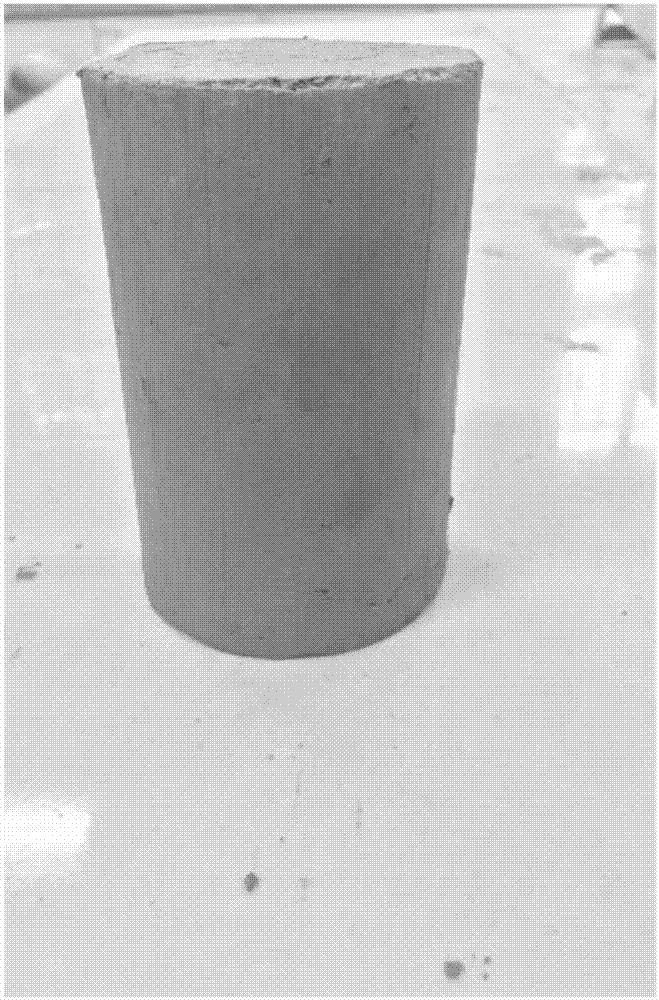

Image

Examples

Embodiment 1

[0025] A preparation method of laboratory water grouting soil is realized through the following steps:

[0026] Step 1, after the soil is air-dried and crushed, pass through a 2mm sieve, then take 15kg of sieved soil, prepare wet soil according to the natural moisture content of 25%, that is, take 3.75kg of water, and leave it in a closed container;

[0027] Step 2, take the wet soil obtained in step 1, and the cement is 20% of the wet soil quality; the water-cement ratio is 0.5 to configure the cement grouting soil, and the cement grouting soil includes the following preparation steps:

[0028] Step 2-1, stir the wet soil after standing for 2min,

[0029] Step 2-2, pour 5.625kg of cement slurry into the mixer, mix the wet soil and cement slurry evenly to obtain cement grouting soil;

[0030] In step 3, the cement grouting soil obtained in step 2 is added to the prefabricated mold at one time, and the prefabricated test block is obtained by falling hammer compaction, and the ...

Embodiment 2

[0036] A preparation method of laboratory water grouting soil is realized through the following steps:

[0037] Step 1, after the soil is air-dried and crushed, pass through a 2mm sieve, then take 15kg of sieved soil, prepare wet soil according to the natural moisture content of 25%, that is, take 3.75kg of water, and leave it in a closed container;

[0038] Step 2, take the wet soil obtained in step 1, and the cement is 20% of the wet soil quality; the water-cement ratio is 0.5 to configure the cement grouting soil, and the cement grouting soil includes the following preparation steps:

[0039] Step 2-1, stir the wet soil after standing for 2min,

[0040] Step 2-2, pour 5.625kg of cement slurry into the mixer, mix the wet soil and cement slurry evenly to obtain cement grouting soil;

[0041] In step 3, the cement grouting soil obtained in step 2 is added to the prefabricated mold at one time, and the prefabricated test block is obtained by falling hammer compaction, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

| Size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com