Iron spar powder, guartz sand cement rock-soil similar material and preparation process thereof

A technology of similar rock and soil, crystal sand, applied in energy engineering, mining, water conservancy, transportation fields, can solve the problems that materials cannot be reused, drying time is slow, and the range of mechanical parameters is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

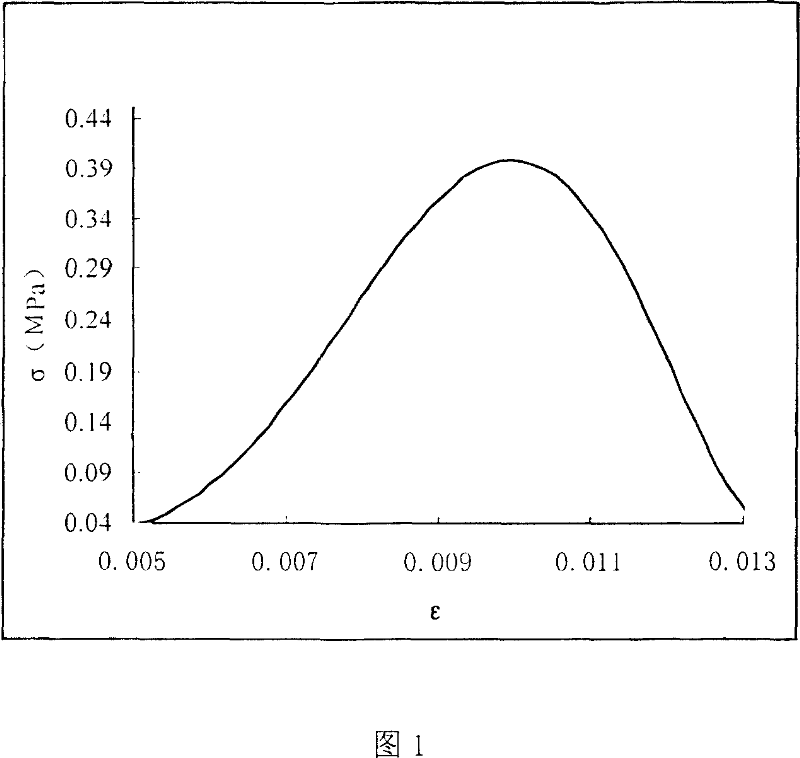

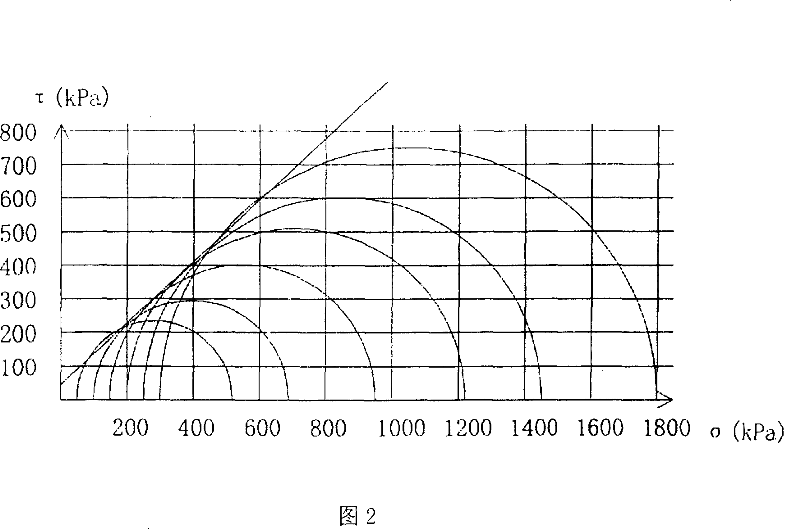

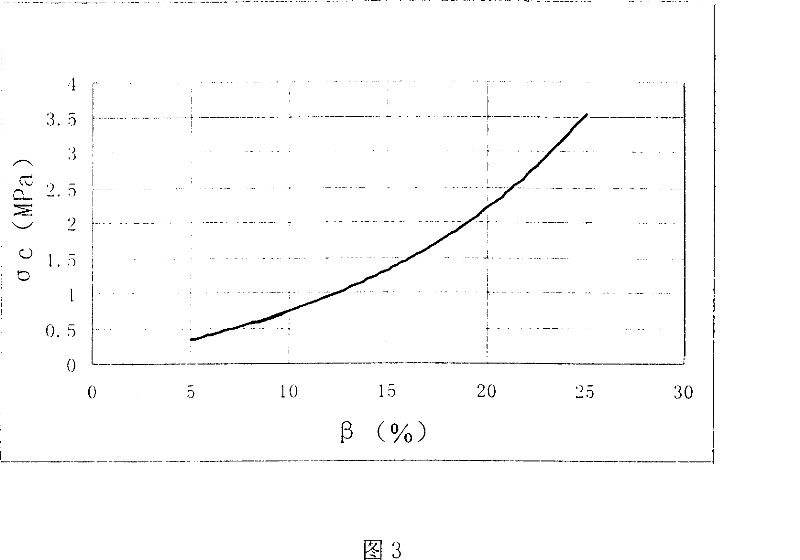

[0044] Embodiment 1 is 1: 0.67: 0.30 in the weight ratio of iron ore powder, barite powder, quartz sand, and gypsum powder accounts for 2.5% of material gross weight, and the molar concentration of rosin alcohol solution is 7.5%, and rosin alcohol solution accounts for material gross weight. In the state of material ratio of 5% by weight, according to the determined material ratio and concentration, first weigh the iron ore powder, barite powder, quartz sand and gypsum powder and pour them into the mixer and stir them evenly, then add rosin alcohol The solution is further stirred, and the mixed material is poured into the steel mold, and the mixed material is compacted under the pressure of 2.0MPa under the press, and finally the mold is disassembled, and the pressed and formed test piece is taken out, and placed at room temperature Dry it for 2-3 days. Finally, the mechanical parameters of the dried material specimens are tested on the testing machine, and the corresponding p...

Embodiment 2

[0045] In embodiment 2, the weight ratio of iron ore powder, barite powder and quartz sand is 1: 1: 0.22, gypsum powder accounts for 4.0% of the material gross weight, and the molar concentration of rosin alcohol solution is 17.5%, and rosin alcohol solution accounts for the total material weight. In the state of material ratio of 5% by weight, according to the determined material ratio and concentration, first weigh the iron ore powder, barite powder, quartz sand and gypsum powder and pour them into the mixer and stir them evenly, then add rosin alcohol The solution is further stirred, and the mixed material is poured into the steel mold, and the mixed material is compacted under the pressure of 2.0MPa under the press, and finally the mold is disassembled, and the pressed and formed test piece is taken out, and placed at room temperature Dry it for 2-3 days. Finally, the mechanical parameters of the dried material specimens were tested on the testing machine, and the mechanic...

Embodiment 3

[0046] Embodiment 3 is 1: 0.43: 0.25 in the weight ratio of iron ore powder, barite powder, quartz sand, and gypsum powder accounts for 3.0% of material gross weight, and the molar concentration of rosin alcohol solution is 25.0%, and rosin alcohol solution accounts for material gross weight. In the state of material ratio of 4% weight, according to the determined material ratio and concentration, first weigh the iron ore powder, barite powder, quartz sand and gypsum powder and pour them into the mixer and stir them evenly, then add rosin alcohol The solution is further stirred, and the mixed material is poured into a steel mold, and the mixed material is compacted under a press with a pressure of 2.0 MPa. Finally, the mold is disassembled, and the pressed and formed test piece is taken out, and placed at room temperature Dry it for 2-3 days. Finally, the mechanical parameters of the dried material specimens were tested on the testing machine, and the mechanical parameters of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com