Geomechanical model similar material for simulating V-class surrounding rock

A geomechanical, model-similar technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of affecting the stability of material properties, difficult to control the mixing ratio, and easy to rust the outer film of iron powder, etc. problem, to achieve the effect of reducing resistance to deformation, low cost, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

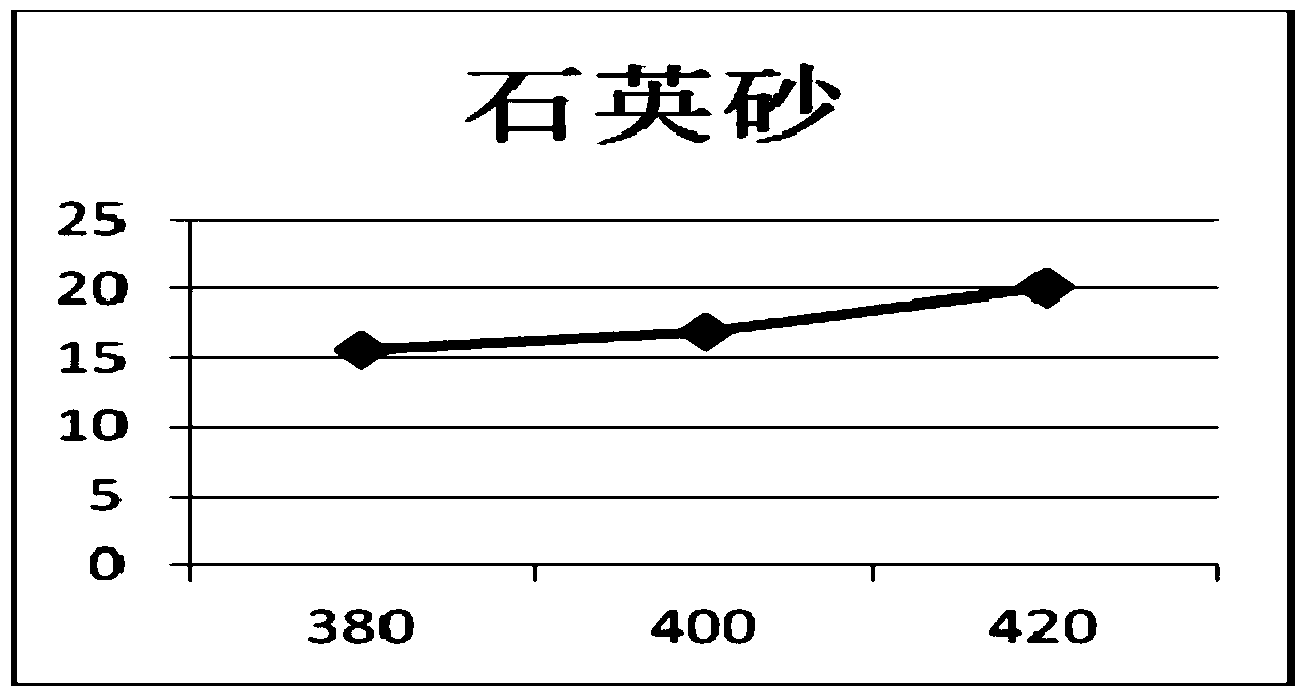

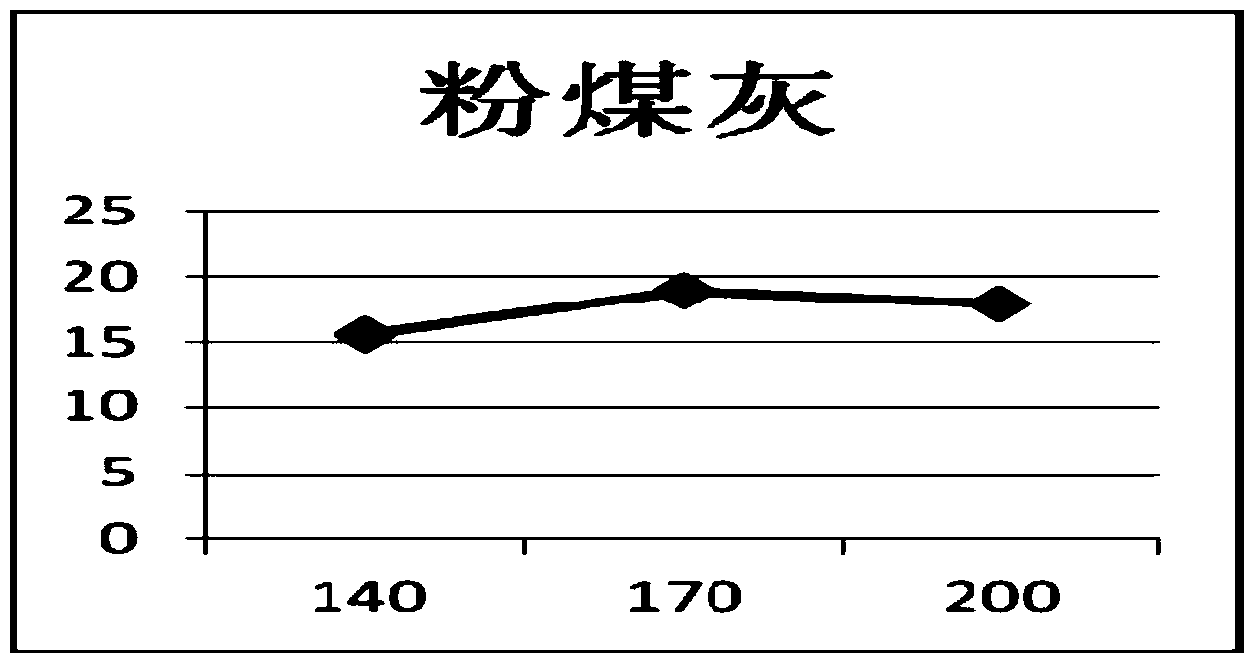

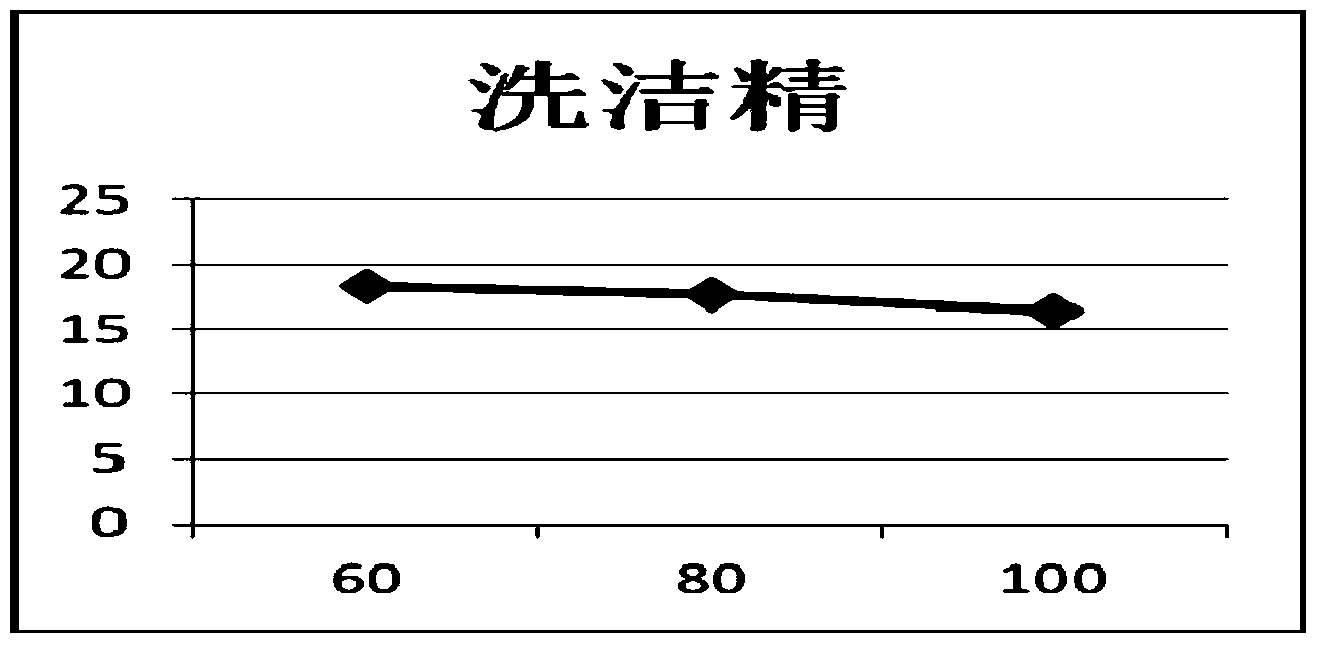

[0034] According to the ratio of quartz sand: fly ash: detergent = 400:170:60, the cohesion force obtained is 1.4283 kPa, and the internal friction angle is 22.264 degrees.

Embodiment 2

[0036] According to the ratio of quartz sand: fly ash: detergent = 400:140:80, the cohesion force obtained is 9.2046 kPa, and the internal friction angle is 13.22 degrees.

Embodiment 3

[0038] According to the ratio of quartz sand: fly ash: detergent = 400:200:100, the cohesion obtained is 15.711 kPa and the internal friction angle is 13.907 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com