A two-component room temperature non-curing asphalt polyurethane waterproof coating and its preparation method

A technology of asphalt waterproof coating and two-component polyurethane, which is applied in the direction of polyurea/polyurethane coating, asphalt coating, coating, etc., can solve the problem of damage to the physical and mechanical properties of coatings, uneven crosslinking degree of coatings, and reduce the performance of waterproof coatings, etc. problems, to achieve stable and excellent physical and mechanical properties, fast curing speed, thorough and uniform crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

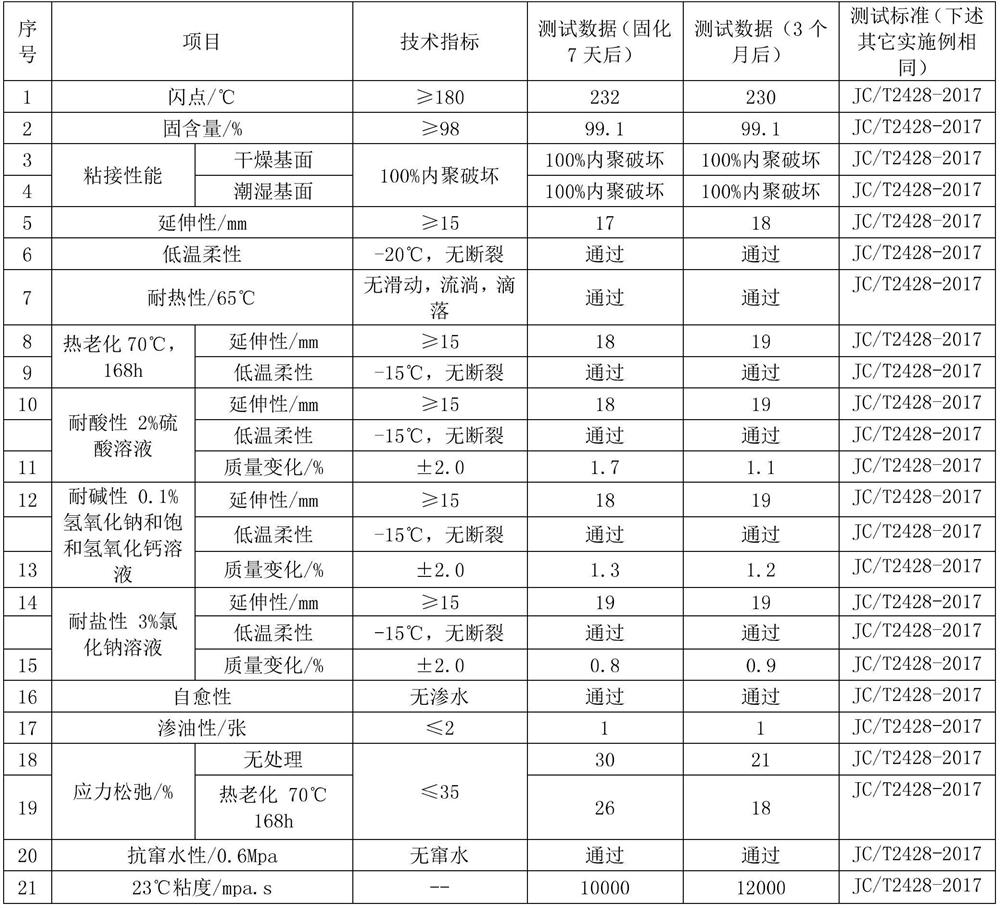

Embodiment 1

[0039] This example provides a two-component room temperature non-curing asphalt polyurethane waterproof coating, including A component and B component. The mass ratio of A component to B component is 1:5; the raw material of A component includes 100kg Dongda Polyether diol 2000, 30kg Dongda polyether triol 3050, 50kg BASF TDI80, 20kg functionality is 2 and number average molecular weight is 2800 hydroxyl-terminated polybutadiene (purchased from Evonik); B group Including 300kg of No. 70 petroleum asphalt, 100kg of talcum powder 1250 mesh, 200kg of DINP plasticizer produced by China Taiwan Liancheng, 130kg of hydroxyl-terminated polybutadiene with a functionality of 2 and a number average molecular weight of 2800 (purchased from Evonik Co., Ltd. ), Xiangyuan Chemical's curing agent MOCA 20kg, asphalt modifier polyethylene wax SLT 3kg, high temperature additive meteorological silica 2kg, zinc isooctanoate 10kg, defoamer 6800 2kg;

[0040] Its preparation method specifically inc...

Embodiment 2

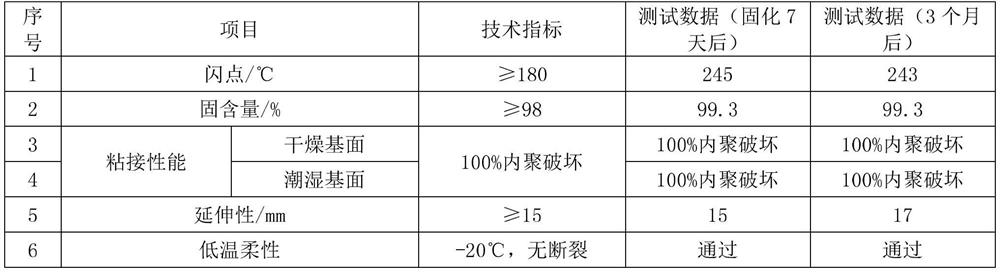

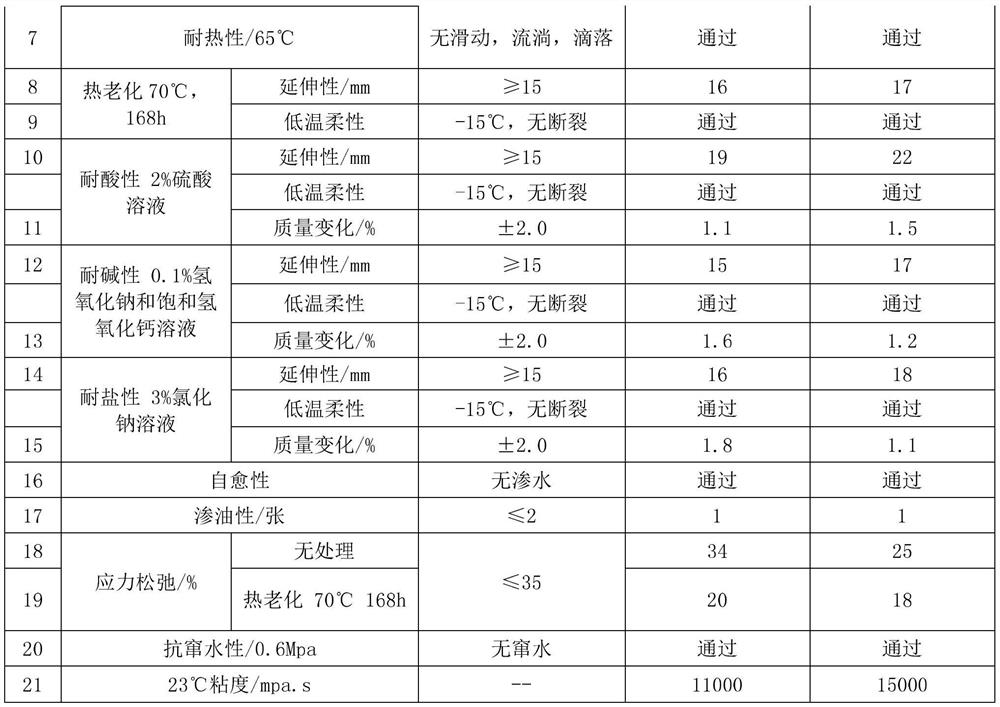

[0046] This example provides a two-component room temperature non-curing asphalt polyurethane waterproof coating, including A component and B component. The mass ratio of A component to B component is 1:5; the raw material of A component includes 110kg Dongda Polyether diol 2000, 80kg BASF MDI, 10kg functionality is 2.2 and number average molecular weight is 3000 hydroxyl-terminated polybutadiene (purchased from Evonik); B component includes No. 70 petroleum asphalt 200kg, titanium dioxide 10kg, heavy calcium 1500 mesh 80kg, 100kg DINP plasticizer produced by China Taiwan Liancheng, 60kg functionality is 2.4 and number average molecular weight is 3000 hydroxyl-terminated polybutadiene (purchased from Evonik Company), Xiangyuan Chemical Co., Ltd. Curing agent ML200 40kg, asphalt modifier polyacetamide wax powder 5kg, high temperature additive nano-calcium 3kg, dibutyltin dilaurate 1kg, defoamer BYK066N 1kg.

[0047] Its preparation method is as follows:

[0048] Preparation of...

Embodiment 3

[0054] This example provides a two-component room temperature non-curing asphalt polyurethane waterproof coating, including A component and B component. The mass ratio of A component to B component is 1:5; the raw material of A component includes 20kg Dongda Polyether diol 2000, polyether triol 330N100kg, 40kg BASF HMDI, 20kgHDI and 10kg hydroxyl-terminated polybutadiene (purchased from Evonik) with a functionality of 2.4 and a number average molecular weight of 2900; B component Including No. 200 petroleum asphalt 200kg, talcum powder 1250 order 100kg, heavy calcium 1500 order 20kg, 150kg China Taiwan Liancheng produced DINP plasticizer, 60kg functionality is 2.4 and the number average molecular weight is 2900 hydroxyl-terminated polybutadiene ( Purchased from Evonik), 40kg of curing agent ML200 from Xiangyuan Chemical, 1kg of asphalt modifier polyacetamide wax powder, 2kg of polyethylene wax, 1kg of high-temperature additive gypsum whisker, 3kg of nano calcium carbonate, cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com