Middle support applied to automobile electric sliding door system

A sliding door, electric technology, applied in the field of middle brackets, can solve the problems of high manufacturing precision of parts, difficult assembly and disassembly, complex structure, etc., and achieves the effect of fast driving speed, reduced volume and weight, and reduced volume and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

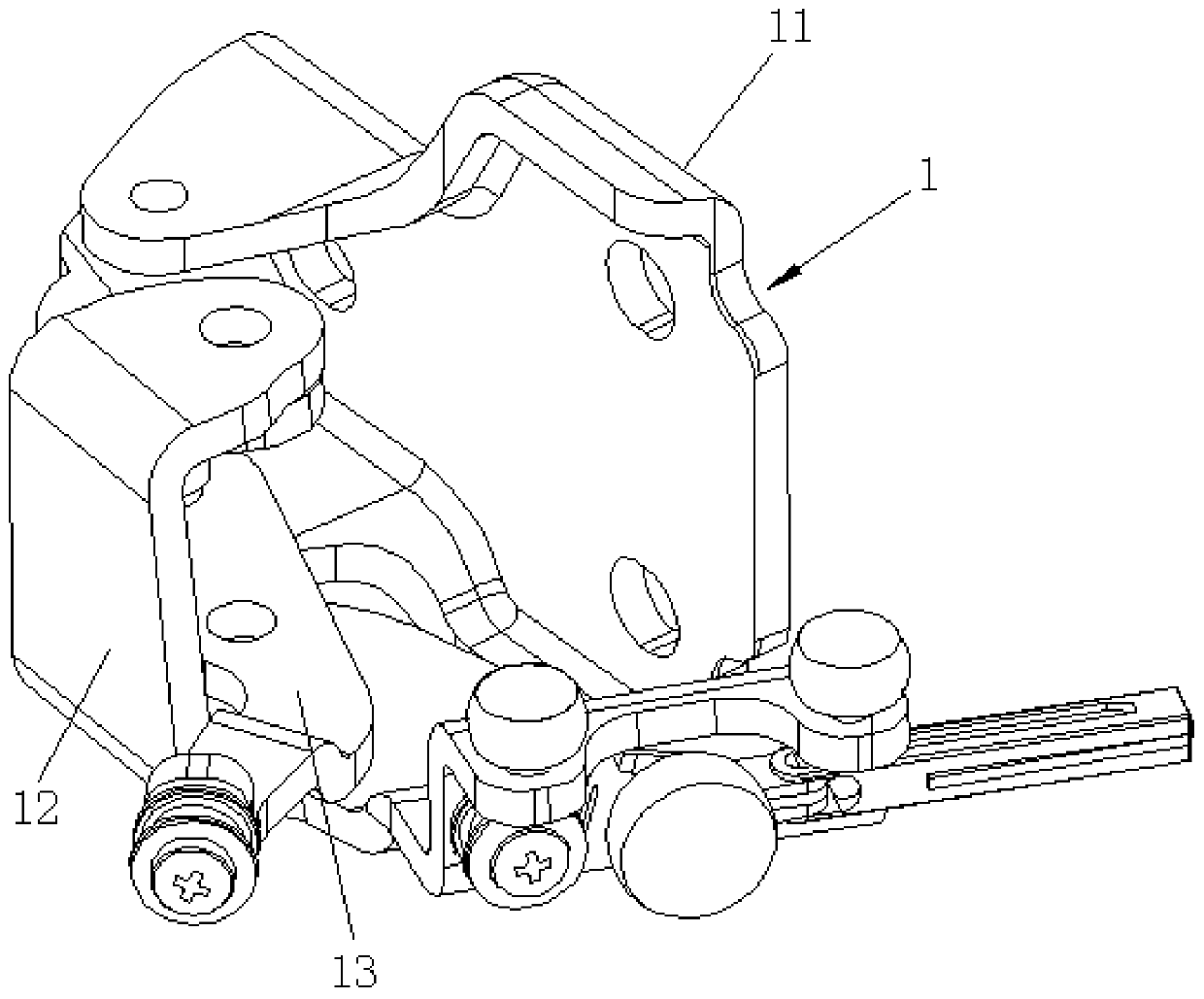

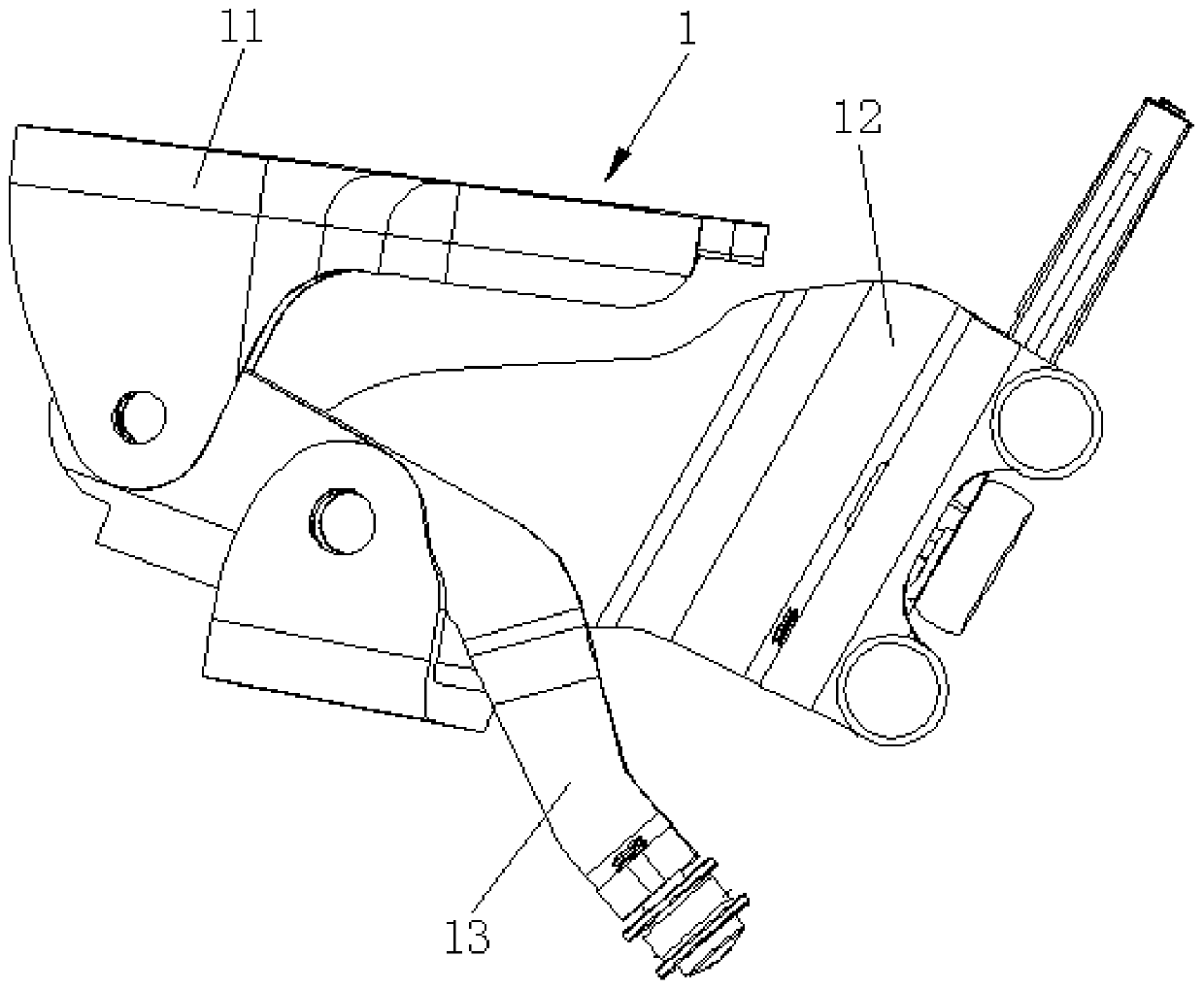

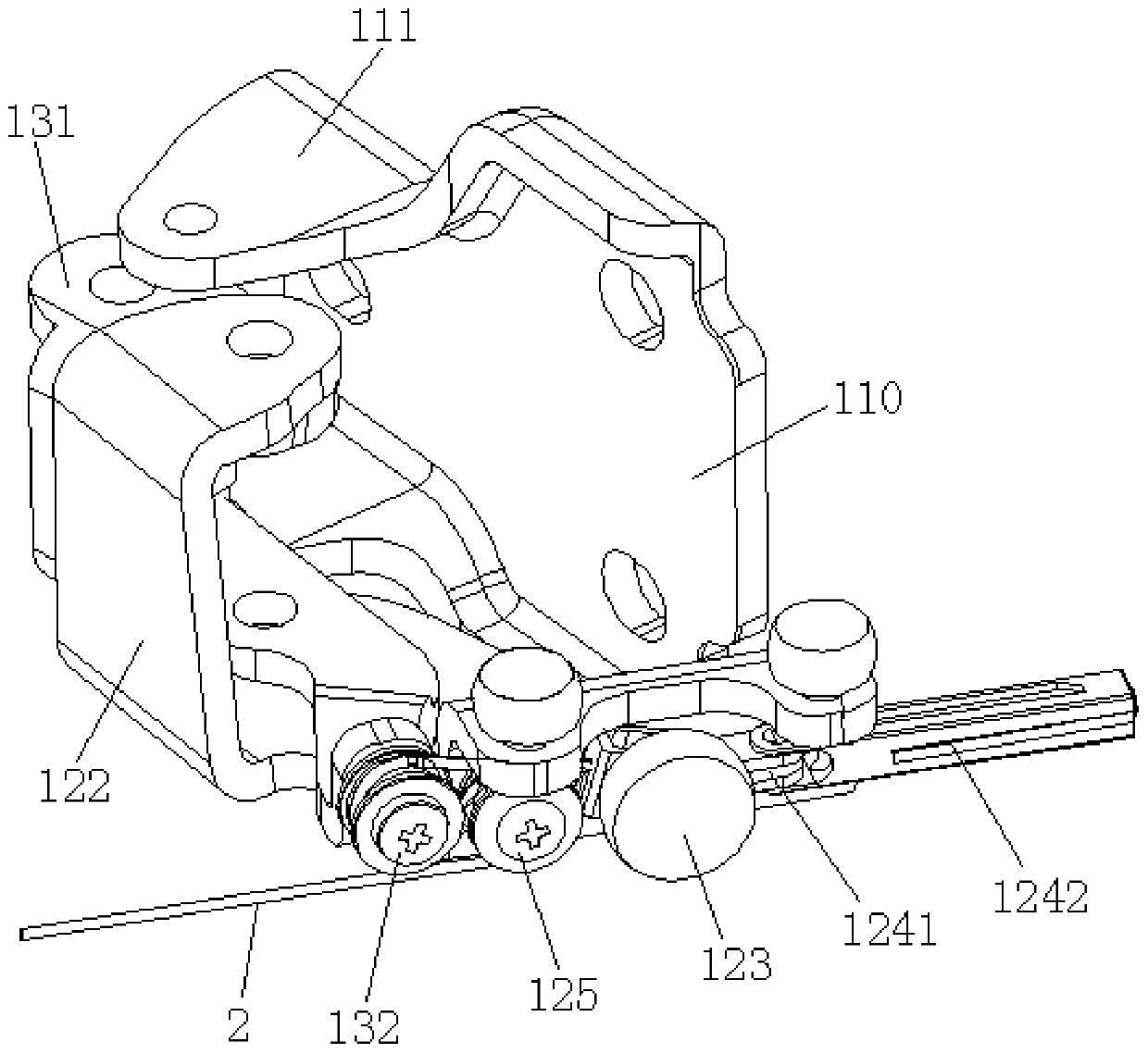

[0046] The automobile electric sliding door system includes a sliding door, a middle guide rail installed on the outside of the side wall of the automobile body, a middle bracket 1 installed at the middle part of the inner side of the sliding door, and a driving mechanism, wherein the middle bracket 1 slides Connected to the middle guide rail, the driving mechanism has two stay ropes 2 (specifically, steel wire stay ropes) connected to the middle bracket 1 respectively, and a pulley that can drive the two stay ropes 2 for telescopic movement. power unit, and the telescopic movement of the two pull ropes 2 can drive the sliding door to open or close the door; in particular, the middle bracket 1 includes a first bracket 11, a second bracket 12 and a booster bracket 13 , see the attached figure 1 to attach Figure 5 As shown, the first bracket 11 is locked and installed at the middle rear part of the inside of the sliding door, the second bracket 12 is placed next to the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com