Multi-stage separate layer fracturing degradable packer and fracturing string

A layered fracturing and packer technology, applied in sealing/isolation, production fluid, wellbore/well components, etc., can solve problems such as sand stuck pipe string, stuck, poor reliability of downhole tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

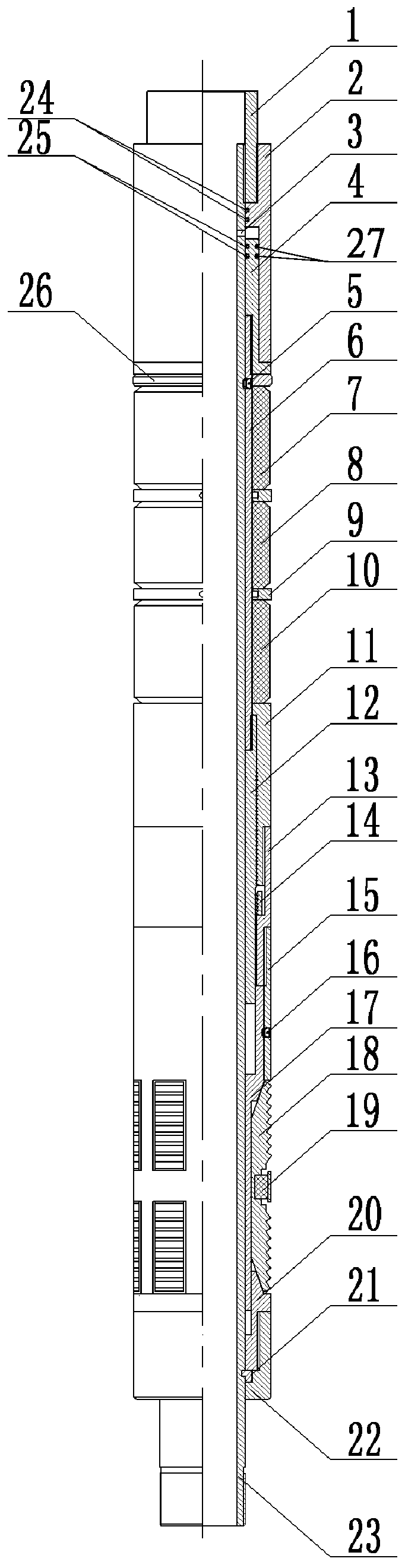

[0026] Such as figure 1 As shown, the degradable packer for multi-stage layered fracturing includes a lower joint 22, a slip mechanism, a stepping mechanism, a rubber cartridge mechanism, a piston mechanism and an upper joint that are sequentially fitted on the outside of the central pipe 23 from bottom to top. 1.

[0027] The slip mechanism includes a slip sleeve 15, an upper cone 17, a slip 18, a spring coil 19 and a lower cone 20;

[0028] The lower cone 20 is set on the outside of the central tube 23, its upper inner wall is inwardly recessed and a first annular step is formed, the middle part of its outer wall is provided with a first annular boss, and its upper outer wall is processed so that its outer diameter gradually increases from top to bottom. large cone;

[0029] The upper cone 17 is set on the outside of the central tube 23, and its upper inner wall and lower outer wall are inwardly recessed and formed with a second annular step and a third annular step, and t...

Embodiment 2

[0048] The degradable packer for multi-stage fracturing in this example is further optimized on the materials of each component on the basis of the degradable packer for multi-stage fracturing in Example 1; specifically,

[0049] The central pipe 23 and the upper joint 1 are made of high-strength and non-degradable high-strength alloy steel, which are used to bear the large pressure load during the sealing operation and connect with the fracturing string; the stepping body 12 and the stepping ring 14 Made of tough and non-degradable spring steel; piston pin 5 and slip pin 16 are made of brass;

[0050] The upper supporting rubber cylinder 7, the sealing rubber cylinder 8, the lower supporting rubber cylinder 10, the spring ring 19 and all sealing rings are made of degradable rubber, specifically, the degradable rubber is polyurethane rubber mixed with a certain proportion of carbon black and The outer surface of the rubber material is covered with potassium dihydrogen phosphat...

Embodiment 3

[0054] Further considering the problem that the strength of degradable materials is lower than that of steel, in order to improve the performance of the packer and ensure that the degradable materials will not be damaged under high pressure, the multi-stage layered fracturing in this embodiment The degradable packer further optimizes the size of each part on the basis of the degradable packer for multi-stage layered fracturing in Example 2; specifically,

[0055] The thread on the inner wall of the upper joint 1 is 2-7 / 8"TBG tubing buckle, and its outer diameter is 94mm;

[0056] The outer diameter of the central pipe 23 is 73mm and the inner diameter is 55mm, and four pressure transmission holes with a diameter of 5mm are opened on it to realize the effective transmission of the packer setting pressure; the inner diameter of the central pipe 23 is larger than that of the commonly used All kinds of 5-1 / 2" fracturing packers should have a large inner diameter (46mm), which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com