Safety bolt

A safety bolt and locking bolt technology, applied in the field of safety bolts, can solve the problems of personal injury of maintenance personnel, fall of the furnace cover, damage of the furnace cover, etc., and achieve the effects of long service life, reasonable and stable structure, and compact volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

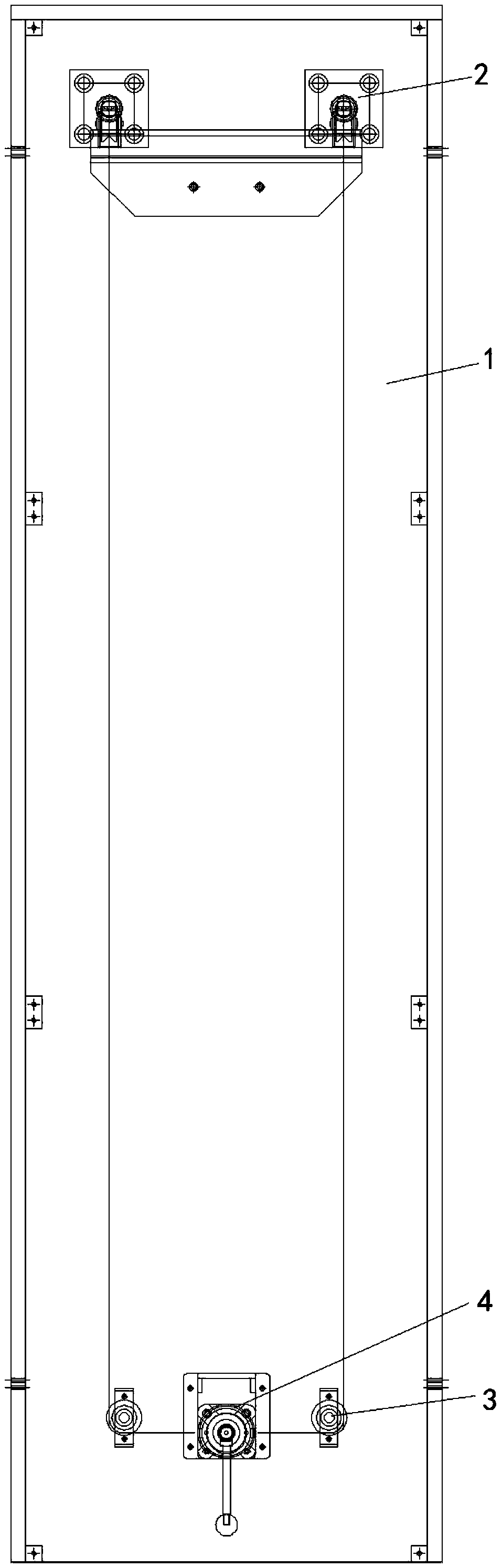

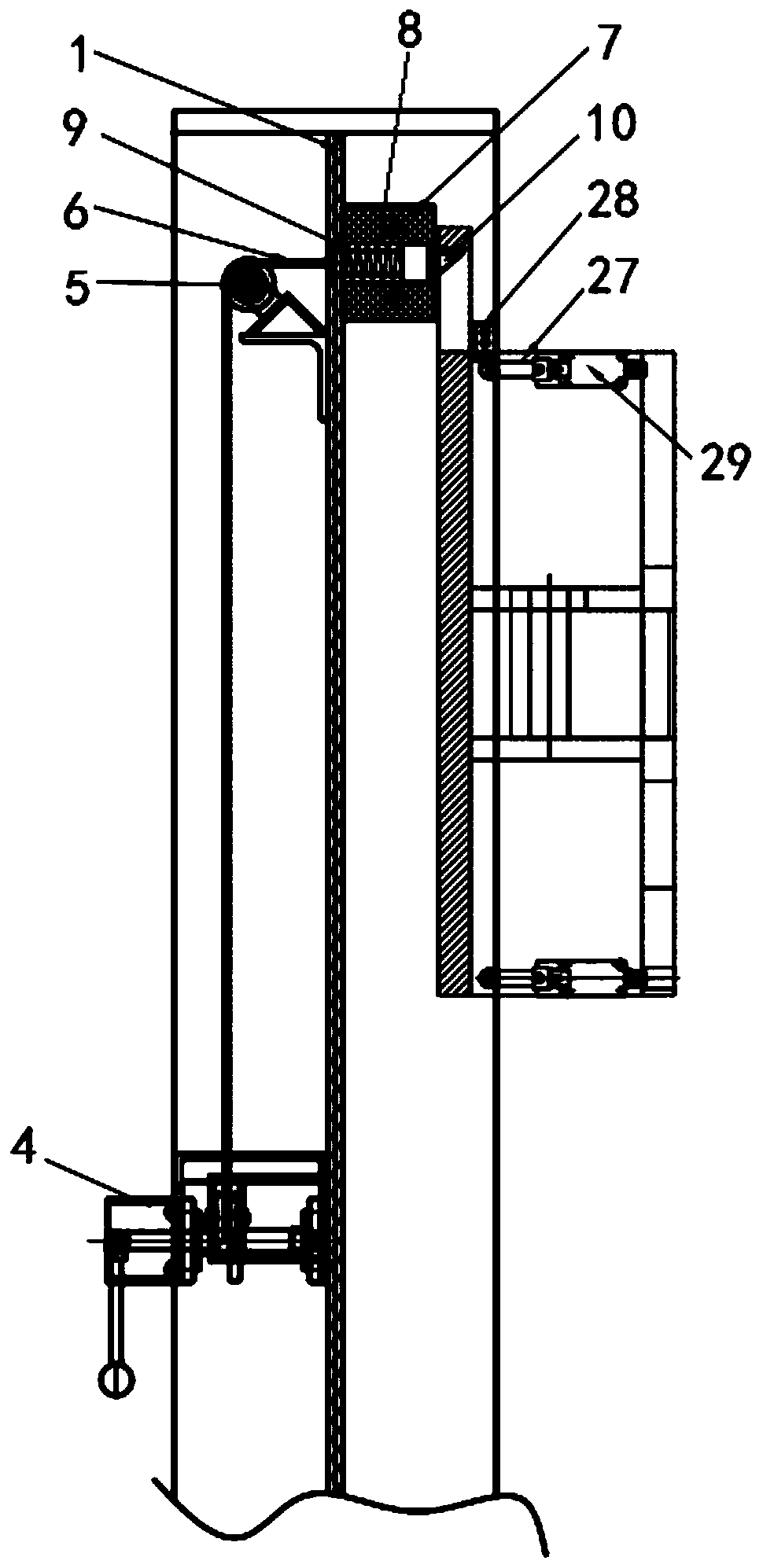

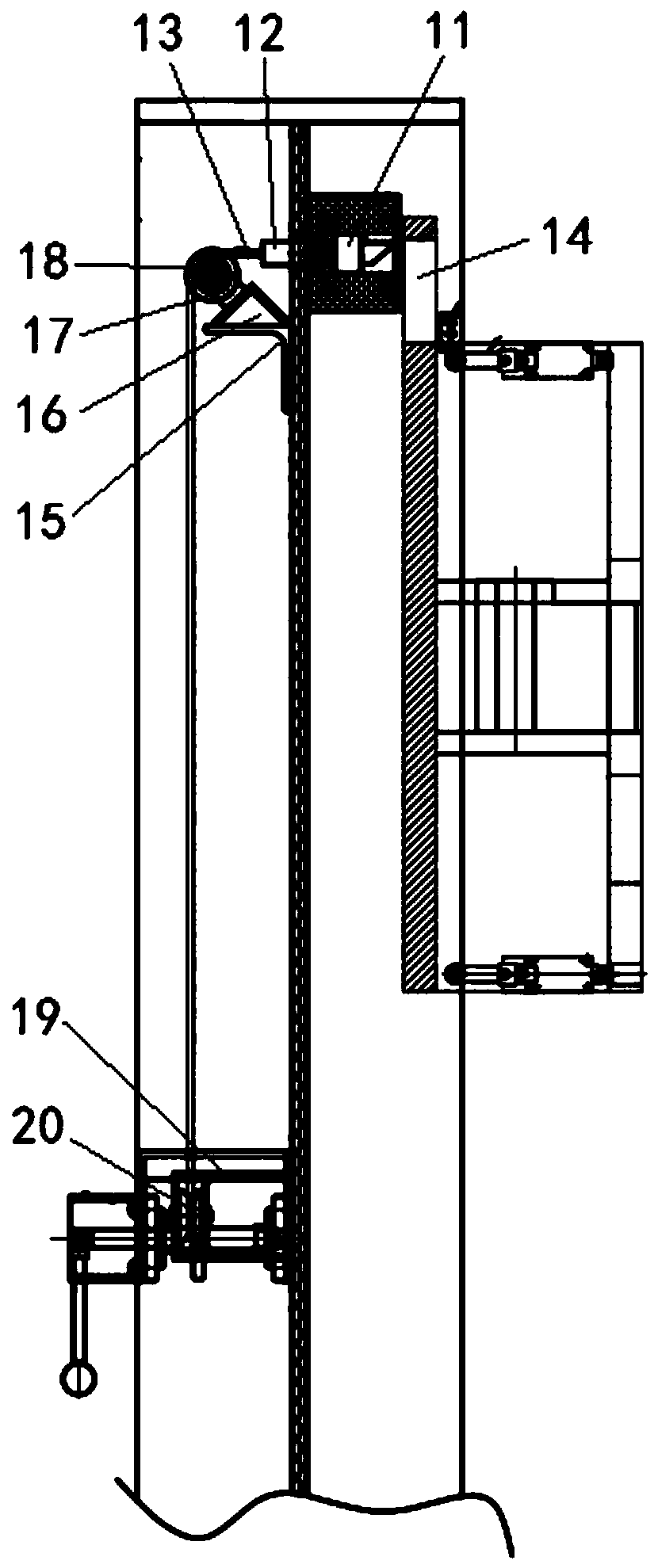

[0023] like Figure 1-3 As shown, it is a safety bolt structure of a preferred embodiment of the present invention, including a pair of latch assemblies 2, two wire ropes 6, a pair of reversing wheel assemblies 5, a pair of positioning pulley 20 assemblies 3 and a manual bolt 4, The latch assembly 2 is installed on the front of the column mounting plate 1, and the centers of the two latch assemblies 2 are located on the same horizontal line. On the latch assembly 2, a wire rope lock 13 protrudes from the back of the column mounting plate 1. The wheel assembly 5 and the positioning pulley 20 assembly 3 are installed on the back side of the column mounting plate 1, and the centers of the two redirecting wheel assemblies 5 are located on the same horizontal line, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com