Servo motor transmission for full-automatic steel plastic strip bundling machine

A servo motor and fully automatic technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as different, inconvenient adjustment of binding force, and inability to meet the requirements of the bundled objects, achieving low cost, eliminating the need for manual adjustment, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

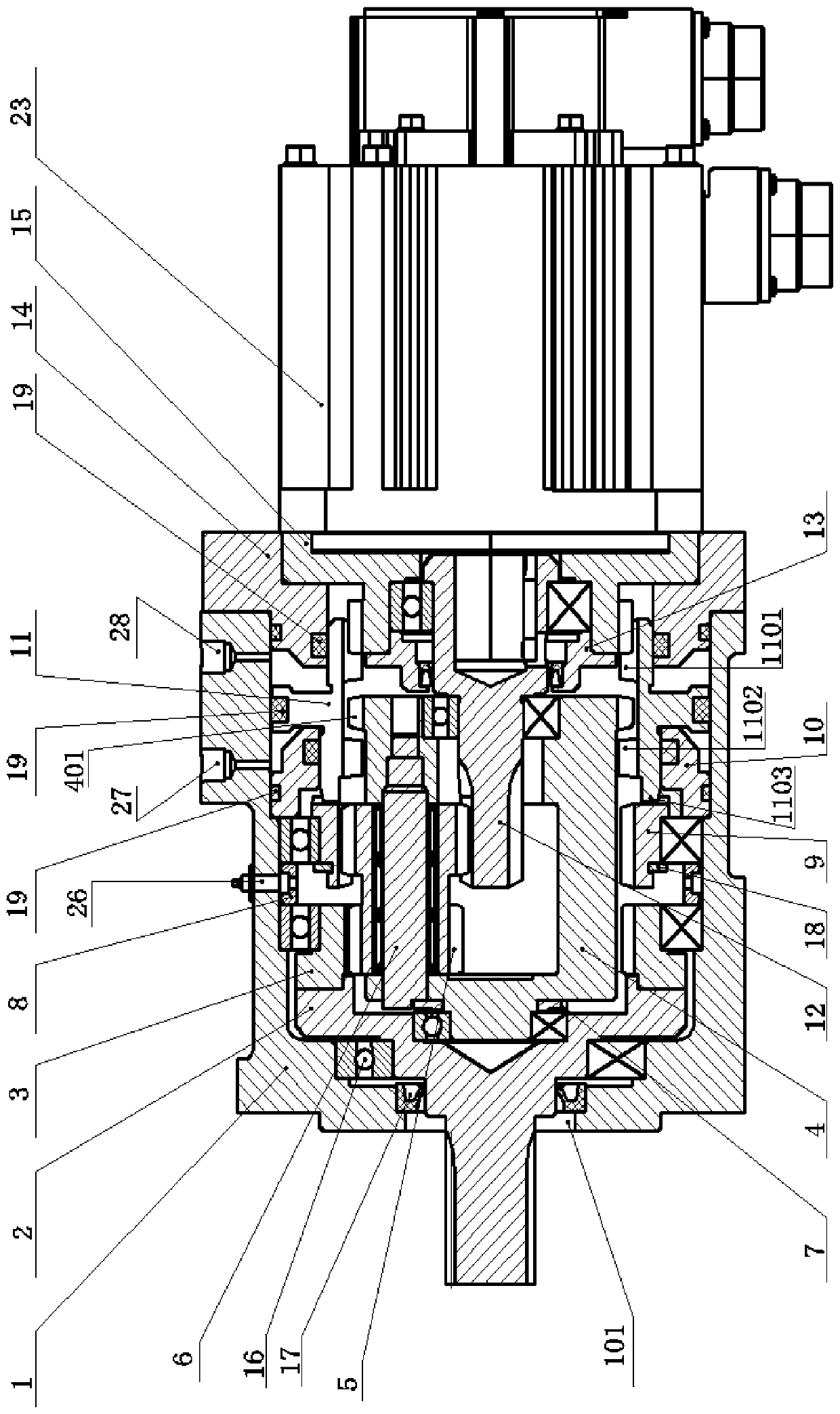

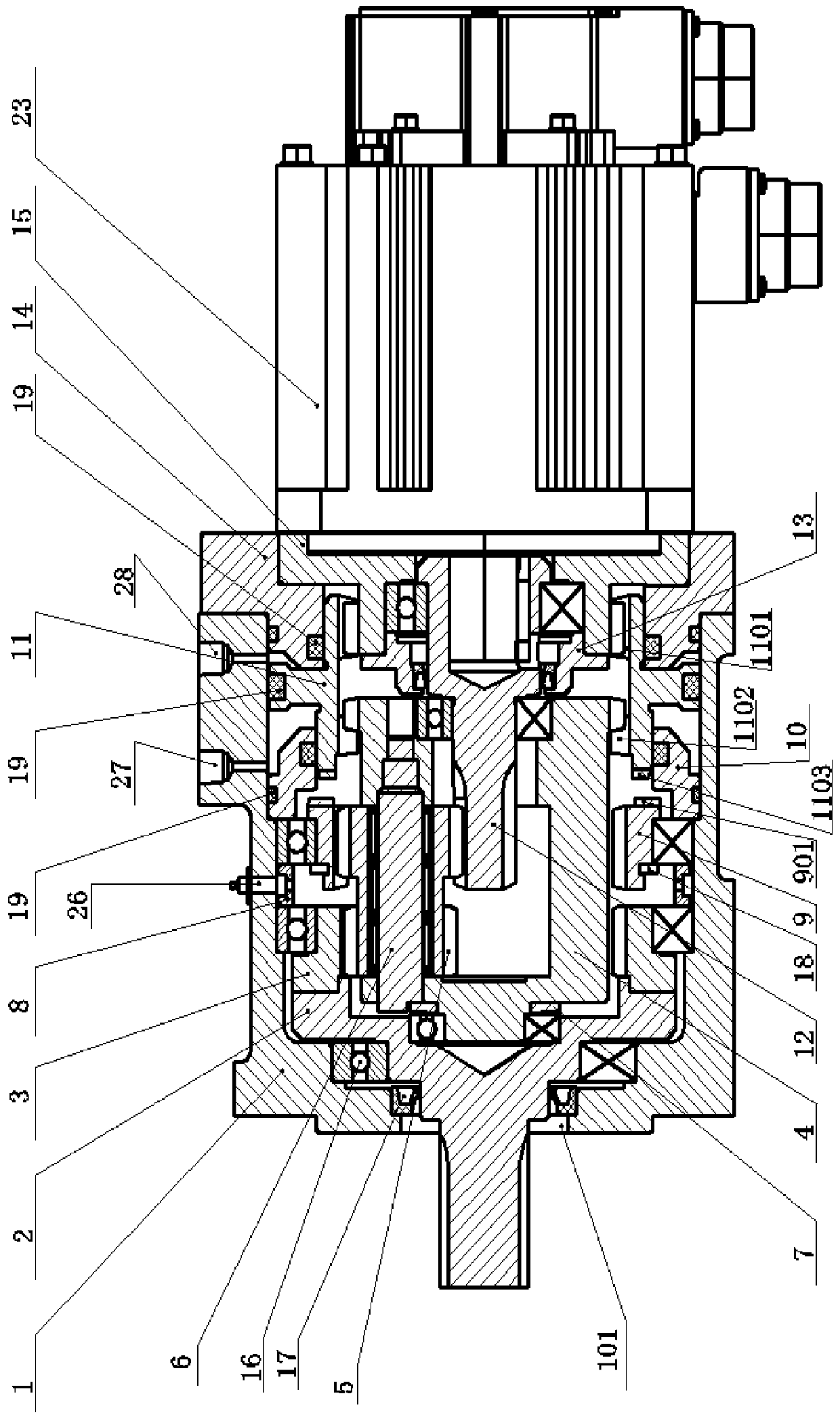

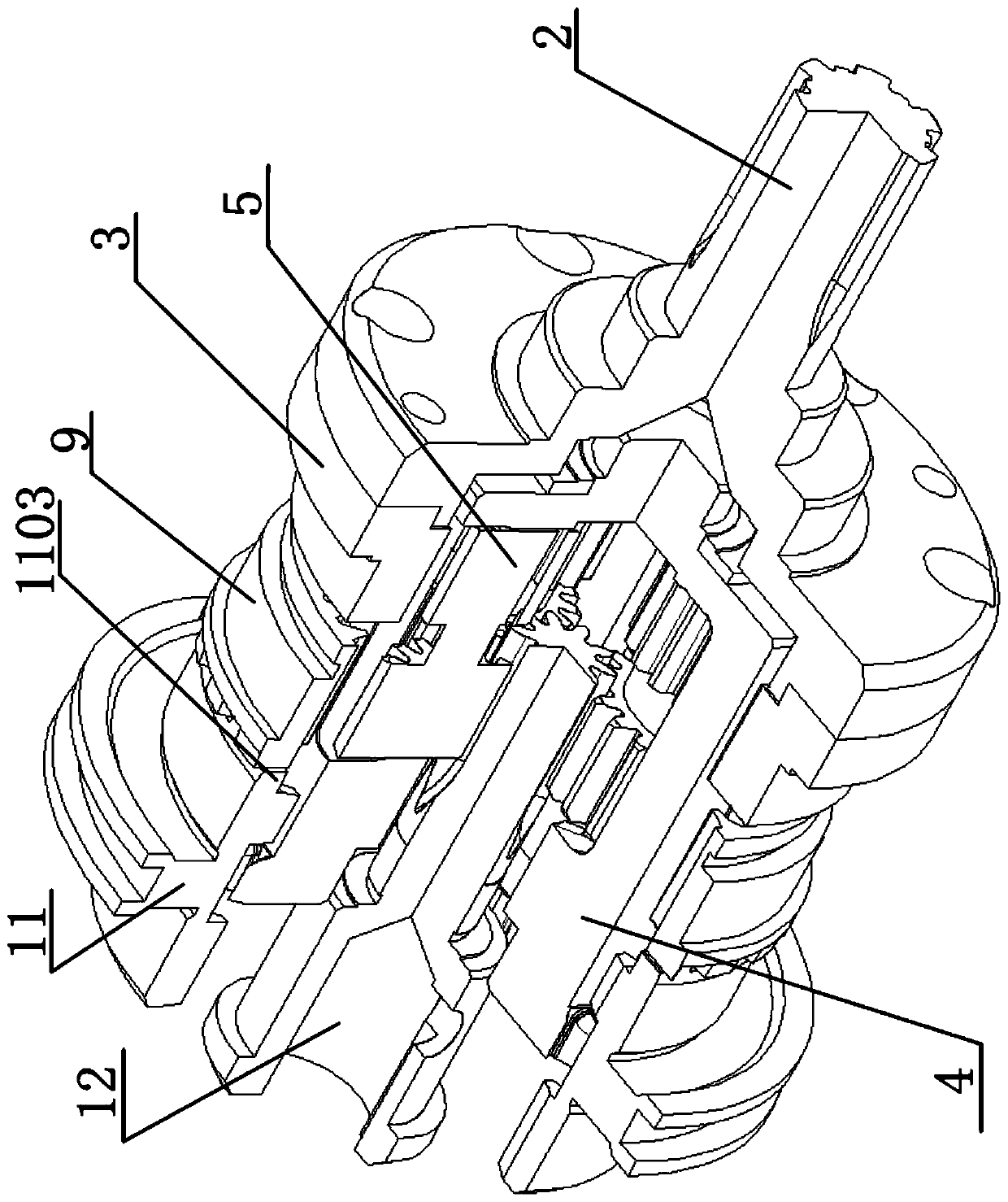

[0031] Such as Figure 1-6 As shown, a servo motor 23 transmission for a fully automatic steel-plastic strapping machine includes a housing 1, a No. 1 internal tooth output shaft 2, a No. 2 internal tooth output shaft 3, a planetary wheel 4, and a No. 1 internal tooth Ring 9, guide ring gear 11, fixed toothed disc 15, dual gear shaft 5, planetary gear shaft 6, central shaft 12, housing back cover 14 and servo motor 23, the housing 1 is a cavity with one side opening body, the opening of the housing 1 is provided with a housing rear cover 14, and the end surface of the housing rear cover 14 away from the housing 1 is provided with a fixed toothed plate 15, and the fixed toothed plate 15 is far away from the housing 1 Servo motor 23 is provided on the end surface of the fixed toothed plate 15, and the end of the fixed toothed plate 15 away from the servo motor 23 is provided with a gland 13, and the outer ring of the housing 1 is provided with a grease nozzle 26, and the outer r...

Embodiment 2

[0036] Such as Figure 1-6 As shown, a servo motor 23 transmission for a fully automatic steel-plastic strapping machine includes a housing 1, a No. 1 internal tooth output shaft 2, a No. 2 internal tooth output shaft 3, a planetary wheel 4, and a No. 1 internal tooth Ring 9, guide ring gear 11, fixed toothed disc 15, dual gear shaft 5, planetary gear shaft 6, central shaft 12, housing back cover 14 and servo motor 23, the housing 1 is a cavity with one side opening body, the opening of the housing 1 is provided with a housing rear cover 14, and the end surface of the housing rear cover 14 away from the housing 1 is provided with a fixed toothed plate 15, and the fixed toothed plate 15 is far away from the housing 1 Servo motor 23 is provided on the end surface of the fixed toothed plate 15, and the end of the fixed toothed plate 15 away from the servo motor 23 is provided with a gland 13, and the outer ring of the housing 1 is provided with a grease nozzle 26, and the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com