Device for testing tensile bending resistance of component line-shaped leading-out end

A lead-out and component technology, applied in measuring devices, using stable bending force to test the strength of materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of inaccurate test results and difficult operation, etc. Achieve the effect of avoiding hand injury by lead wire, improving accuracy and avoiding inconvenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

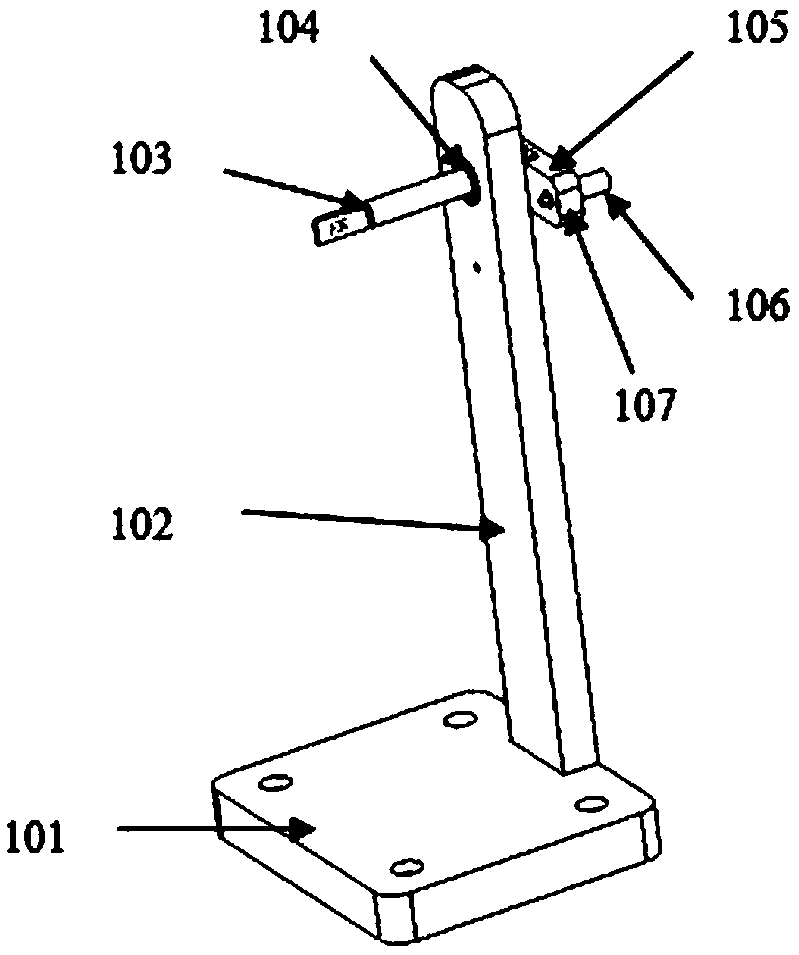

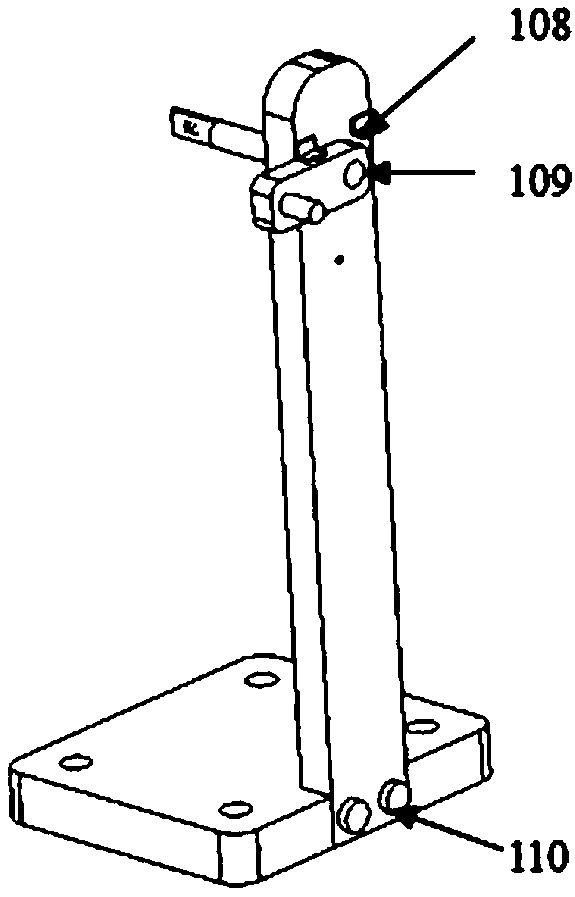

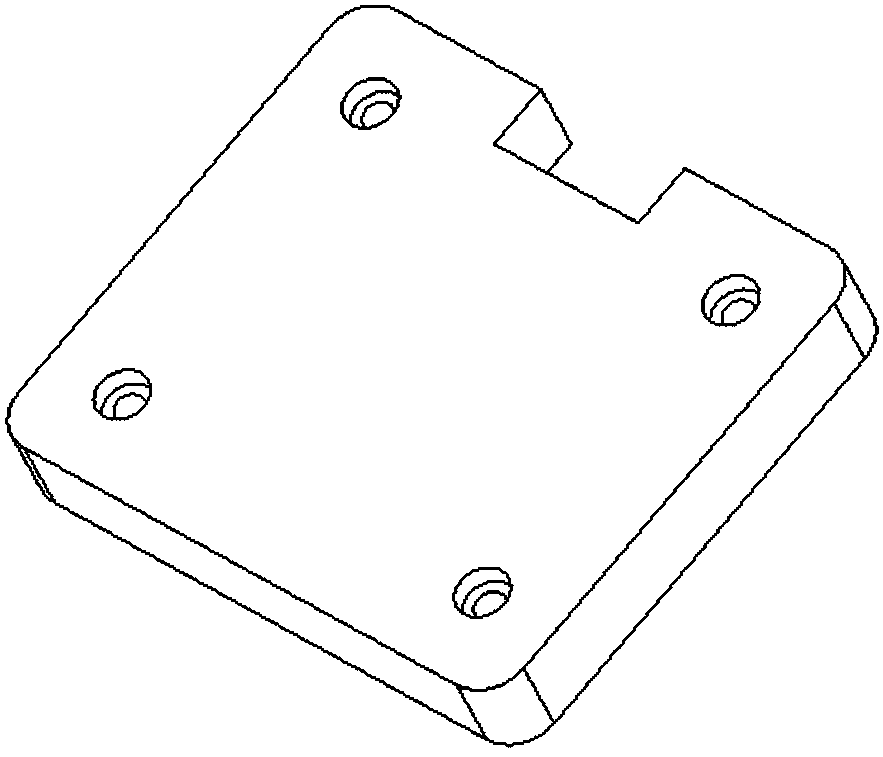

[0024] A device for tensile and bending test of linear terminals of components, see Figure 1 to Figure 11 , the device for the tensile and bending test of the linear lead-out of components includes a horizontal base 101, a vertical bracket 102, a clamp 103, a bearing 104, a rocker 105, a positioning handle 106, a spring 107, and a limit block 108 , fixing screw 109 and connecting screw 110; see figure 1 and figure 2 , the bracket 102 is connected and fixed with the base 101 by a set screw 109; see Figure 6 , the clamp 103 is installed on the bracket 102 through the bearing 104, and the clamp 103 is connected with the rocker 105 through the connecting screw 110; the positioning handle 106 includes a guide section, the spring 107 is set outside the positioning handle 106, and the positioning handle 106 is installed on the rocking bar 105 ; see Figure 10 , the limit block 108 is installed on the bracket 102 and is located above the rocker 105; the positioning handle 106 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com