Gas turbine compressor blade frequency modulation design method

A gas turbine and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as the first-order resonance of compressor blades, achieve stable and reliable operation, simplify the frequency modulation process, and simple design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

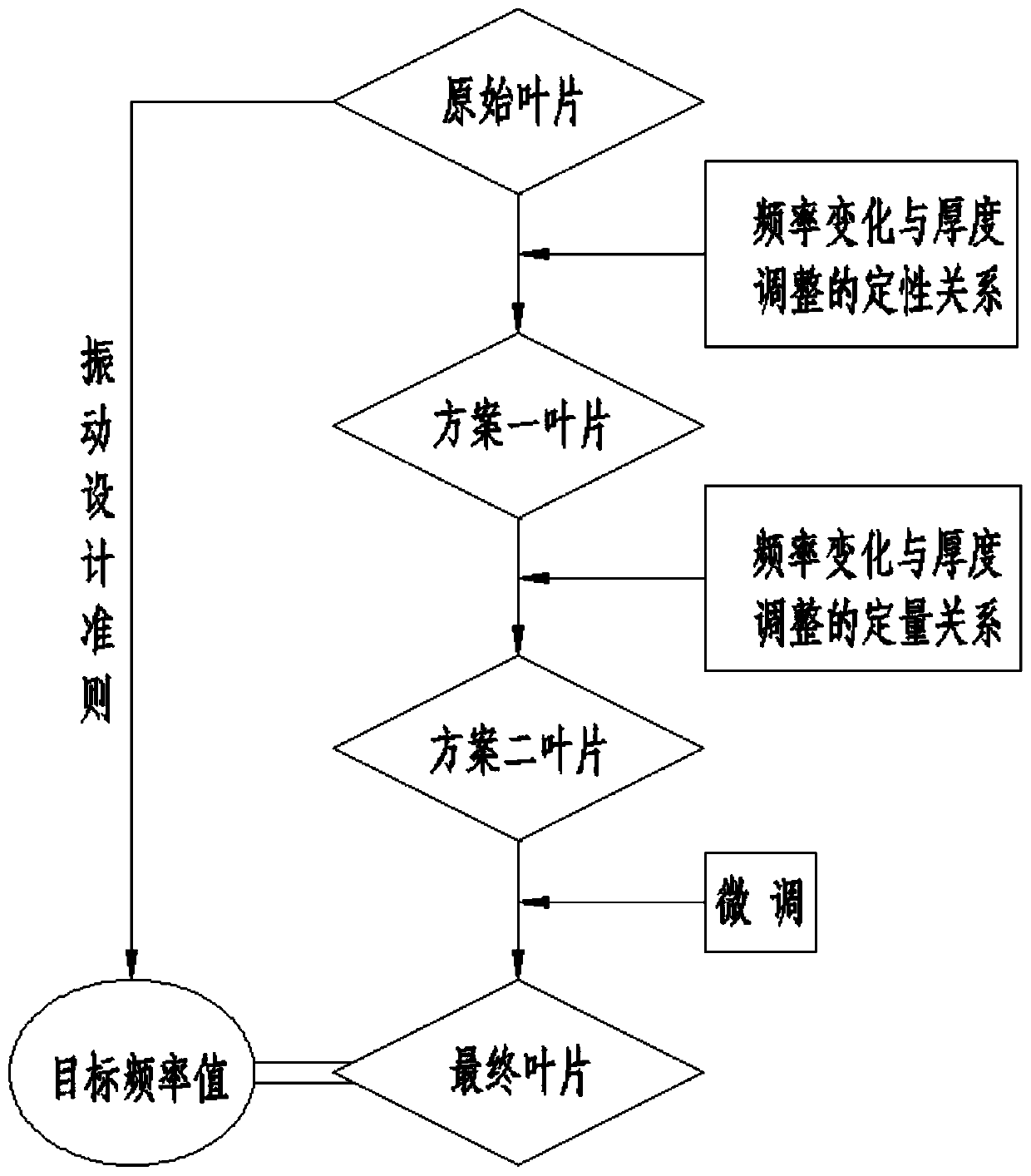

[0024] Specific implementation method: combined figure 1 To describe this embodiment,

[0025] A method for designing frequency modulation of a gas turbine compressor blade provided in this embodiment specifically includes the following steps:

[0026] Step 1, using the finite element calculation and analysis program Ansys Workbench to perform vibration calculations on the compressor blades (original blades) with resonance problems.

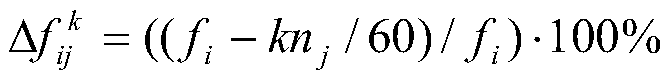

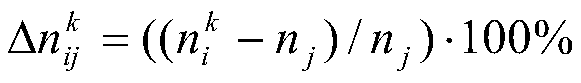

[0027] Step 2. In the blade vibration design criteria, the first-order bending resonance has the following requirements: within the steady-state operating speed range of the engine, there should be no exciting forces from the first to fourth orders of the engine and the known structural factors (previously The resonance caused by the fundamental frequency excitation force generated by the two-stage stator, the last-stage stator, the support plate, etc.); if this type of resonance is unavoidable, the frequency margin and rotational speed margin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com