A motor, an electric power steering device, and a method of manufacturing the motor

A manufacturing method and motor technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve problems such as increased component costs, achieve the effect of easy fixing and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

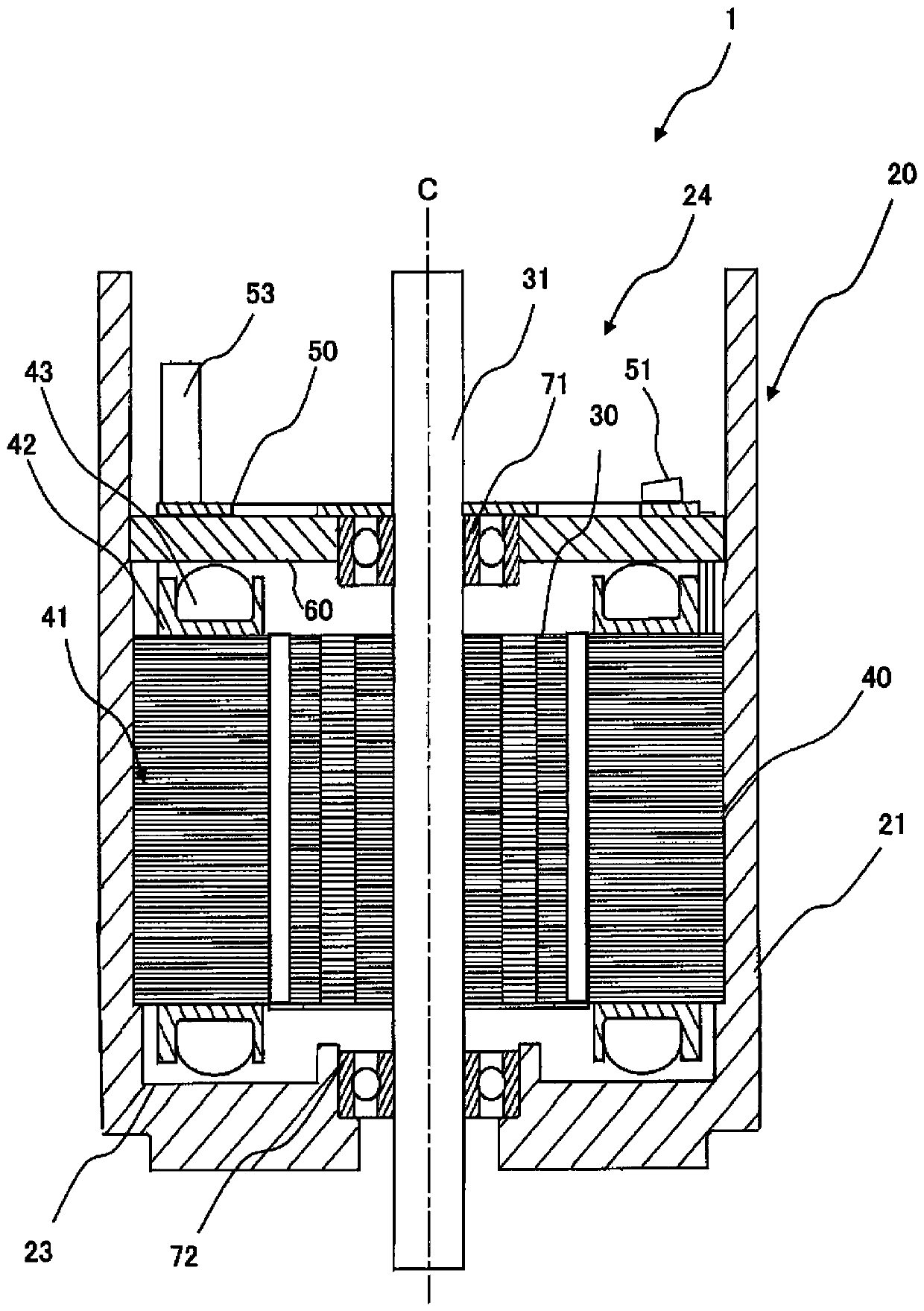

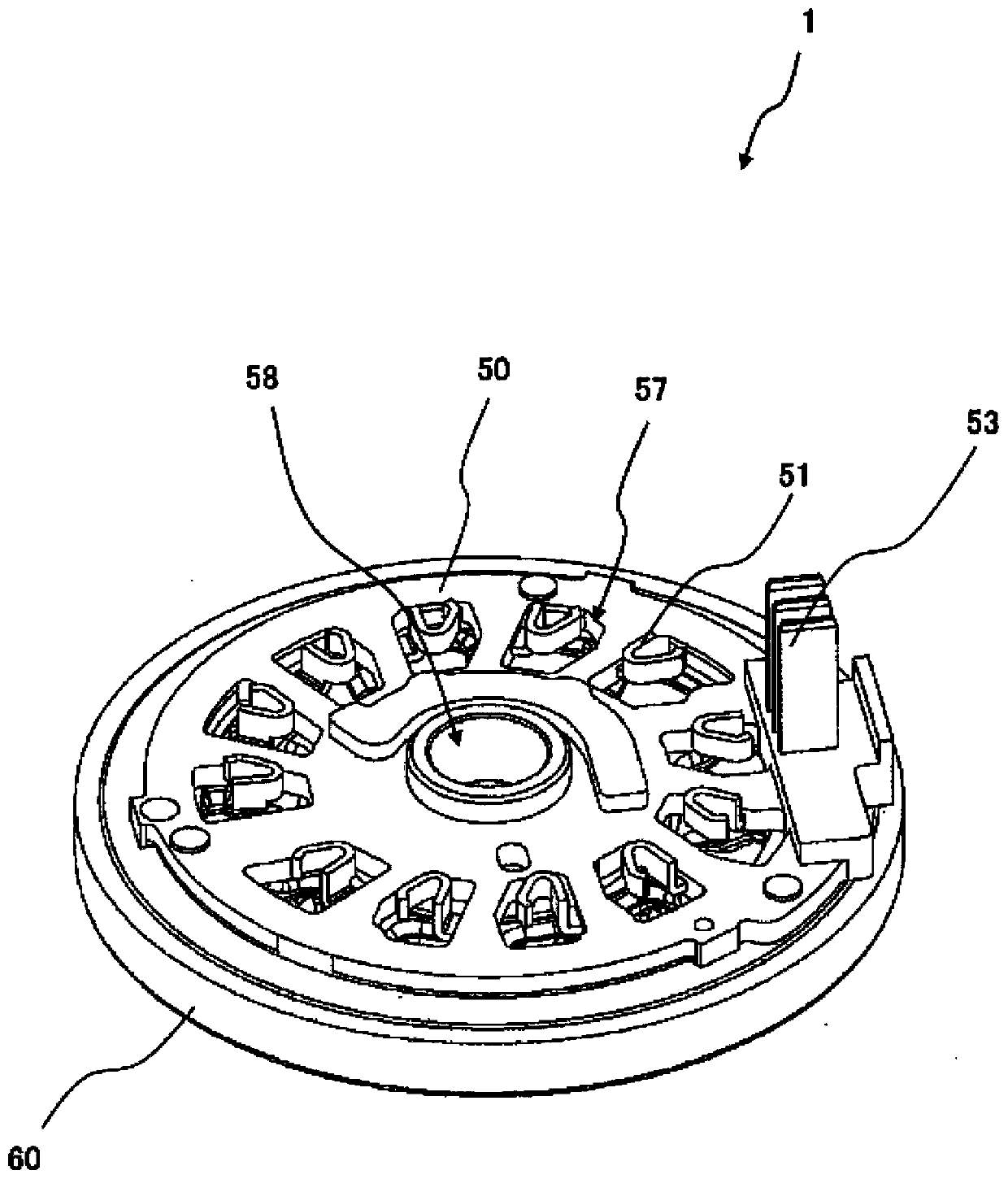

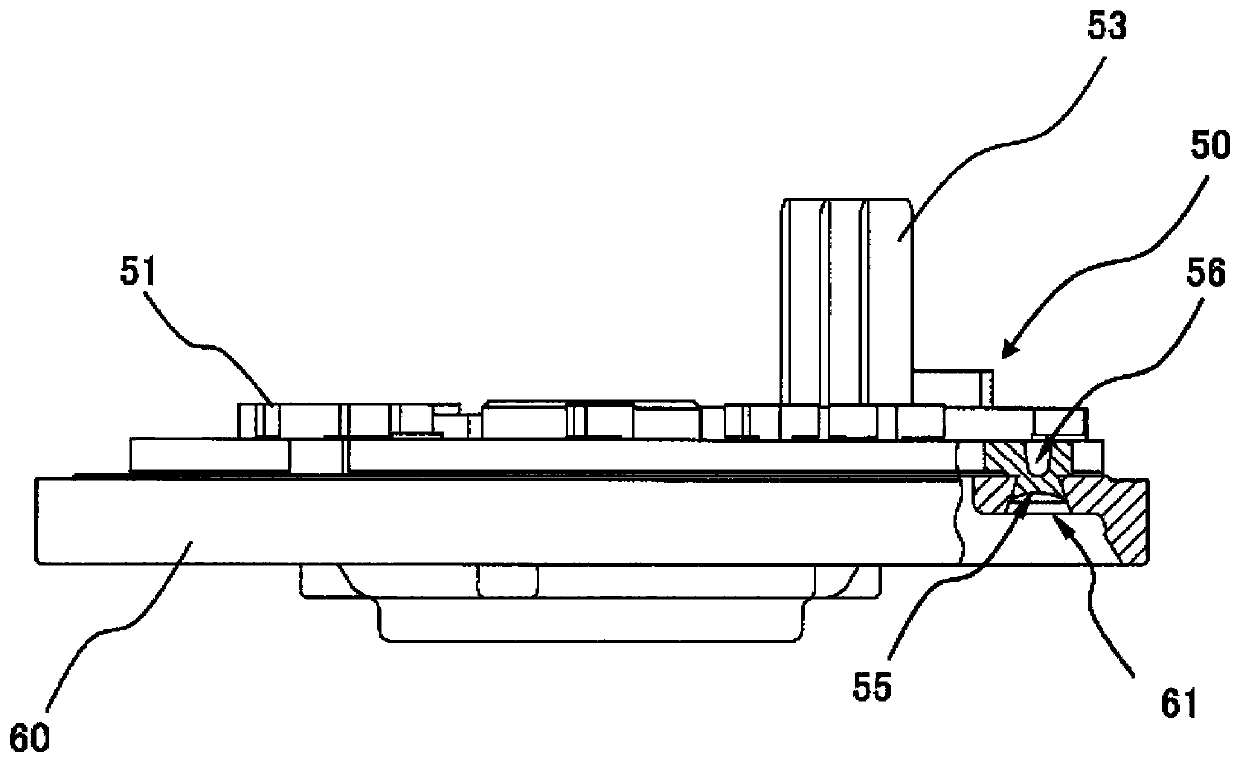

[0021] Such as figure 1 As shown, the motor 1 has a shaft 31 , a rotor 30 , a stator 40 , a housing 20 , a bus bar holder 50 and a bearing holder 60 .

[0022] The shaft 31 extends along the central axis C, and is rotatably supported around the central axis C by an upper bearing 71 and a lower bearing 72 . The rotor 30 is fixed to the shaft 31 and rotates around the central axis C together with the shaft 31 .

[0023] The stator 40 is arranged to face the rotor 30 on the radially outer side of the rotor 30 . The stator 40 has a stator core 41 , an insulator 42 and a coil wire 43 . The insulator 42 is attached to the teeth (not shown) of the stator core 41 . The coil wire 43 is an example of a conductive part, is made of a conductive wire, and is wound around the teeth via the insulator 42 . Lead wires drawn upward from the stator 40 from the coil wire 43 wound on the stator 40 are connected to a bus bar 51 described later.

[0024] The housing 20 is disposed radially outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com