Segment, segment assembly, and grouting apparatus

A technology of segment and main body, which is applied in segment assembly, grouting device and segment field, which can solve problems such as water leakage and inability to close the cover, so as to improve mobility and sealing force, simplify grouting operation, and strengthen the function of preventing backflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

[0032] First, the embodiments described below are suitable for understanding the technical features of the segment, the segment assembly, and the grouting device of the present invention. However, the embodiments described below do not limit the technical features of the present invention, and various modifications can be made within the technical scope of the present invention.

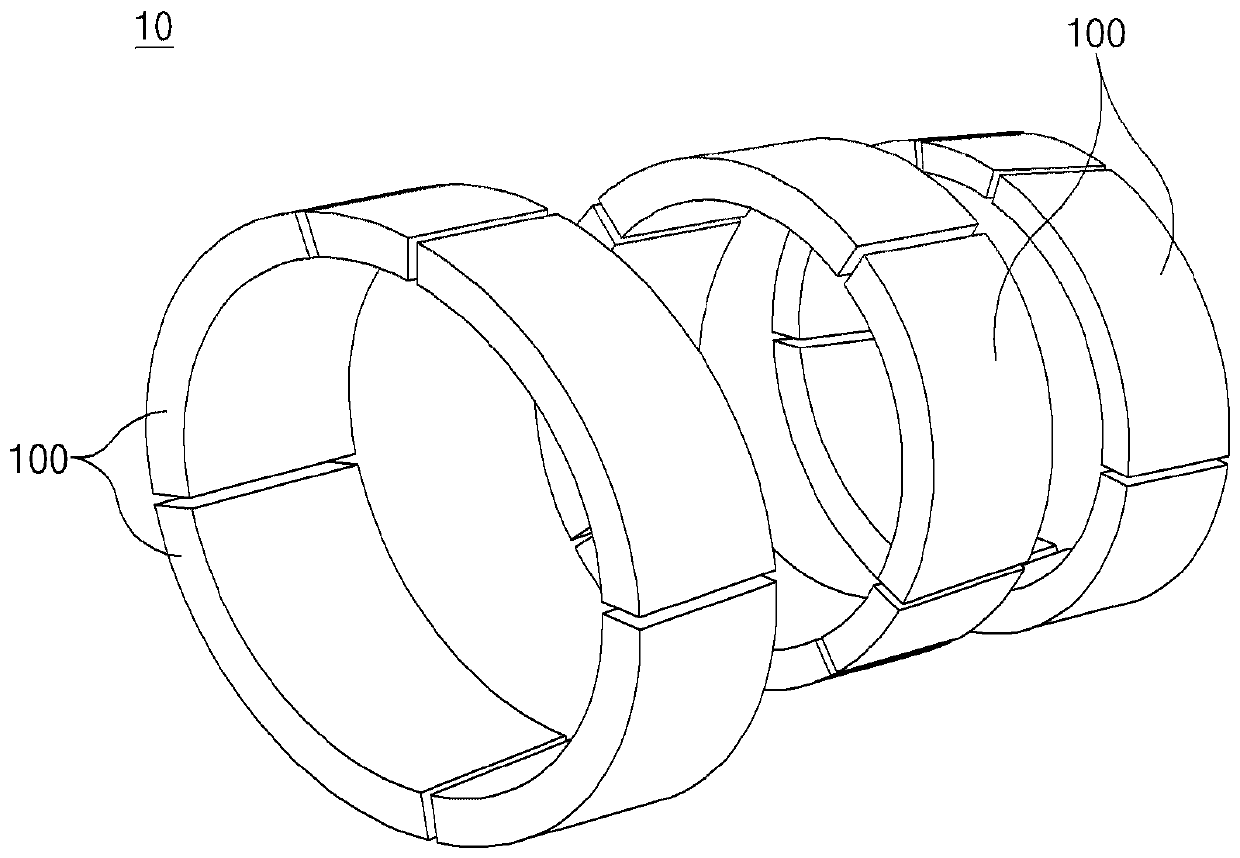

[0033] refer to figure 1 and figure 2 In the illustrated embodiment, according to the segment assembly 10 of the present invention, a plurality of segment segments 100 can be connected to each other. Here, the method of assembling the plurality of segments 100 is not limited, and various methods are applicable as long as they can be assembled firmly.

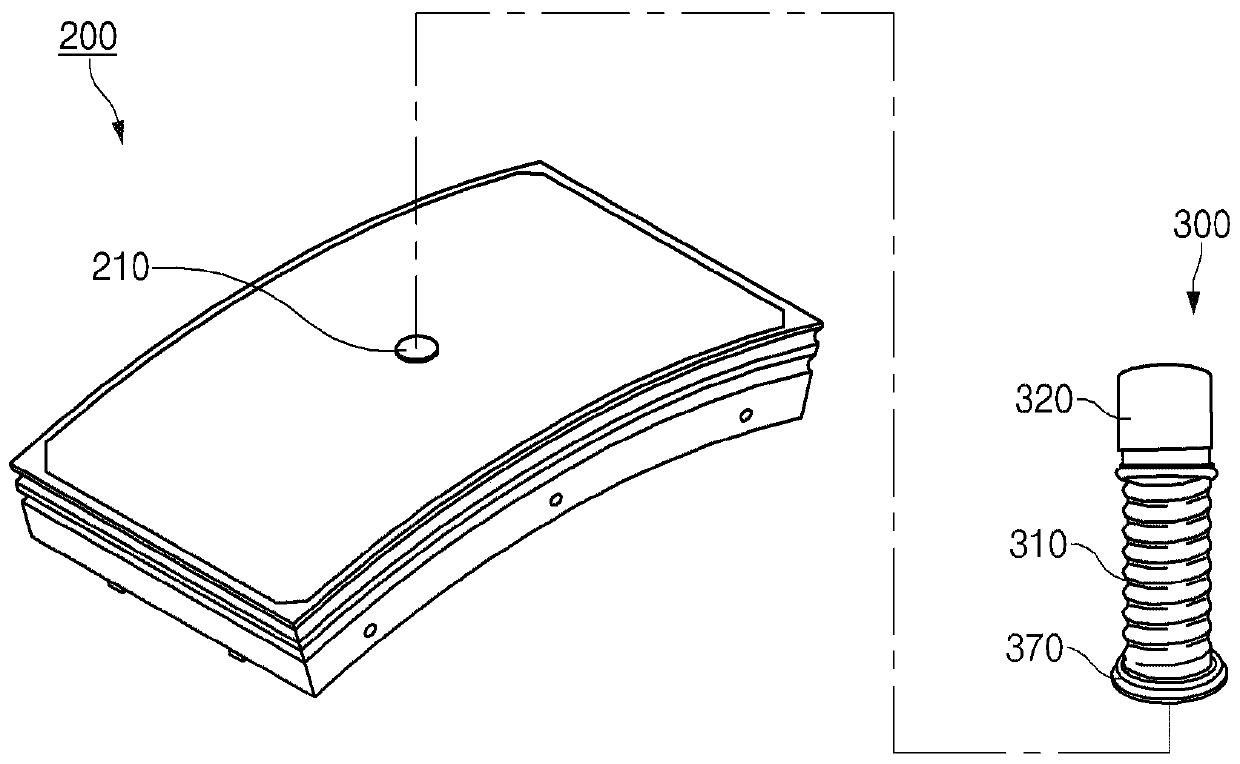

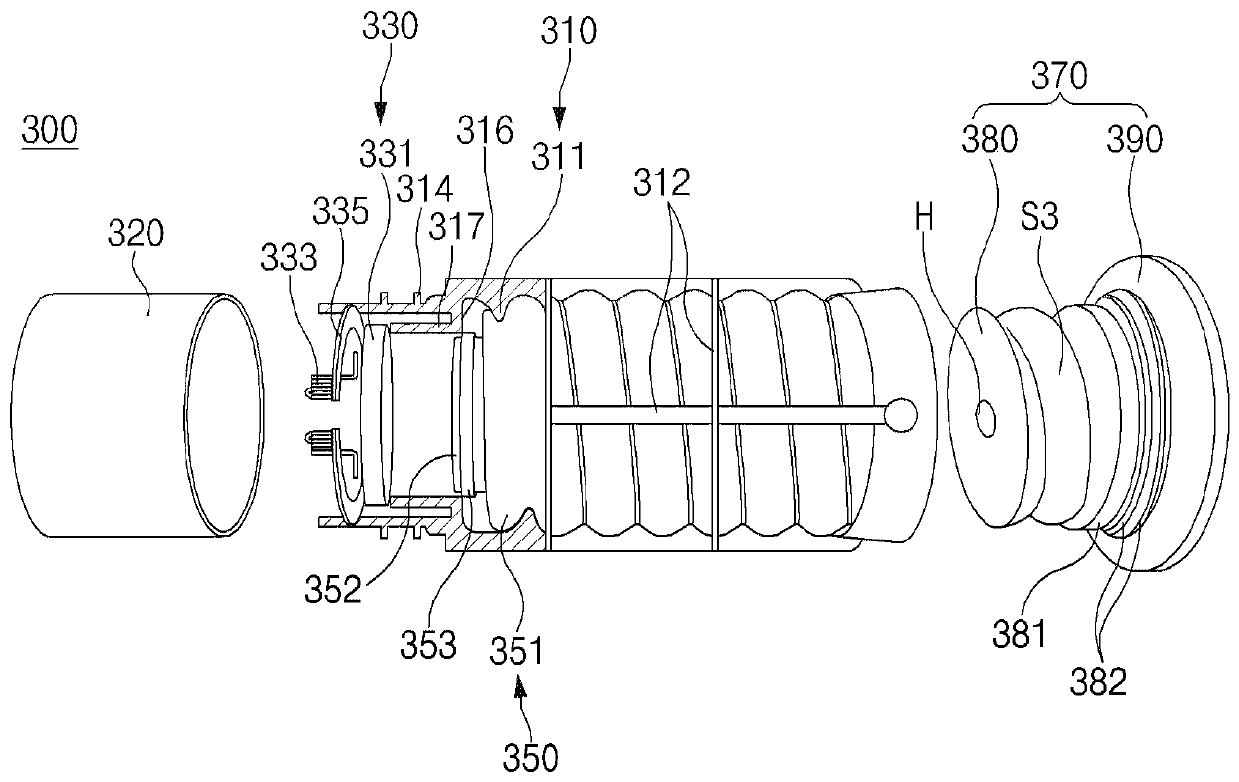

[0034] The segment 100 according to the present invention includes a segment body 200 and a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com