Preparation method of instant partridge tea powder

The technology of partridge tea powder and partridge tea is applied in the direction of tea substitutes, etc., which can solve the problems of unacceptable, rough production and processing methods, backwardness, etc., and achieves the effects of mellow taste and increased health care efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

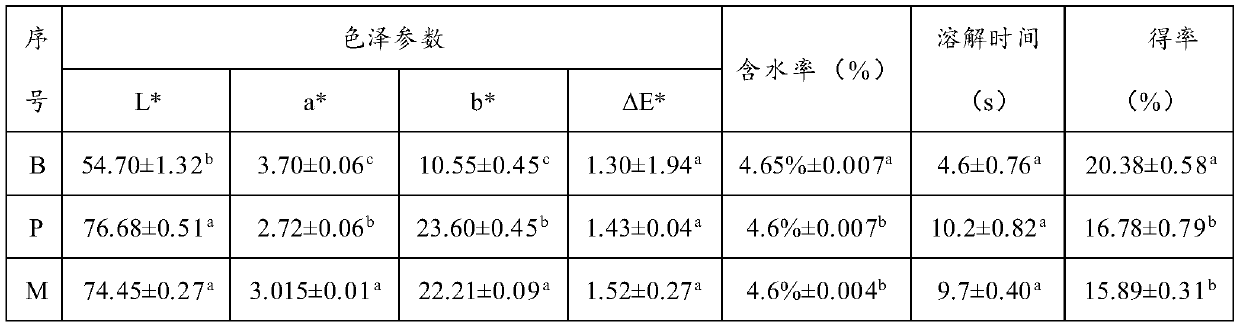

[0027] Aiming at the low-level, low-tech and low-efficiency production process of partridge tea, this application provides a preparation process of instant partridge tea powder. The preparation process does not destroy the original nutrients and active ingredients of partridge tea In this way, the prepared instant partridge tea powder has good instant solubility, good smell and good cold dissolving effect, which satisfies the drinking needs of more people. Concretely, the preparation method of the instant partridge tea powder described in the application comprises the following steps:

[0028] A) Pretreating fresh partridge tea leaves, carrying out hot water extraction and coarse filtration of the pretreated partridge tea leaves to obtain an extract;

[0029] B) purifying the extract by ultrafiltration and then concentrating by reverse osmosis to obtain a concentrate;

[0030] C) freeze-drying the concentrated solution to obtain a freeze-dried powder, and primary pulverizing ...

Embodiment 1

[0052] (1) picking fresh partridge tea leaves, removing branches and stalks, and drying in the sun or mechanically to obtain dried partridge tea leaves with a moisture content of ≤6%;

[0053] (2) Take 20 kg of crushed dry tea of partridge tea, pour it into an extraction tank, inject 400L of water and heat up to 85°C, extract for 40 minutes, filter to obtain the first extract and partridge tea dregs, and then pour it into the partridge tea Add 100L of water to the tea dregs, extract at 85°C for 15 minutes, filter to obtain the second extract, mix the two extracts, cool to 4°C, and pass through a stainless steel filter to remove visible tea dregs to obtain a crude filtrate;

[0054] (3) Under the conditions of 10±2° C. and 0.2 MPa, the crude filtrate is ultrafiltered through a ceramic membrane with a pore size of 0.1 μm, and then concentrated by a reverse osmosis membrane until the solid content is 20%;

[0055] (4) The concentrated liquid is placed in a freezer at -18°C for ...

Embodiment 2

[0060] (1) picking fresh partridge tea leaves, removing branches and stalks, and drying in the sun or mechanically to obtain dried partridge tea leaves with a moisture content of ≤6%;

[0061] (2) Take 20 kg of crushed dry tea of partridge tea and pour it into an extraction tank, inject 500L of water and heat up to 75°C for extraction for 50 minutes, filter to get the first extract and partridge tea dregs, and then add partridge tea dregs Add 100L of water to the mixture, extract at 75°C for 20 minutes, filter to obtain the second extract, mix and cool the two extracts to 4°C, and remove visible tea dregs through the filter to obtain the crude filtrate;

[0062] (3) Under the conditions of 10±2° C. and 0.2 MPa, the crude filtrate is ultrafiltered through a ceramic membrane with a pore size of 0.1 μm, and then concentrated by a reverse osmosis membrane until the solid content is 20%;

[0063] (4) The concentrate is placed in a -18°C freezer for quick freezing for 4.5 hours; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com