Circulating water self-cleaning structure and process of washing tower

A technology of washing tower and circulating water, applied in the field of circulating water self-purification structure and process, and the field of circulating water self-purification structure and process of washing tower, can solve the problems of time-consuming and labor-intensive, filtration efficiency decline, influence on waste gas treatment efficiency, etc., and achieve good filtration effect. , good purification effect, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

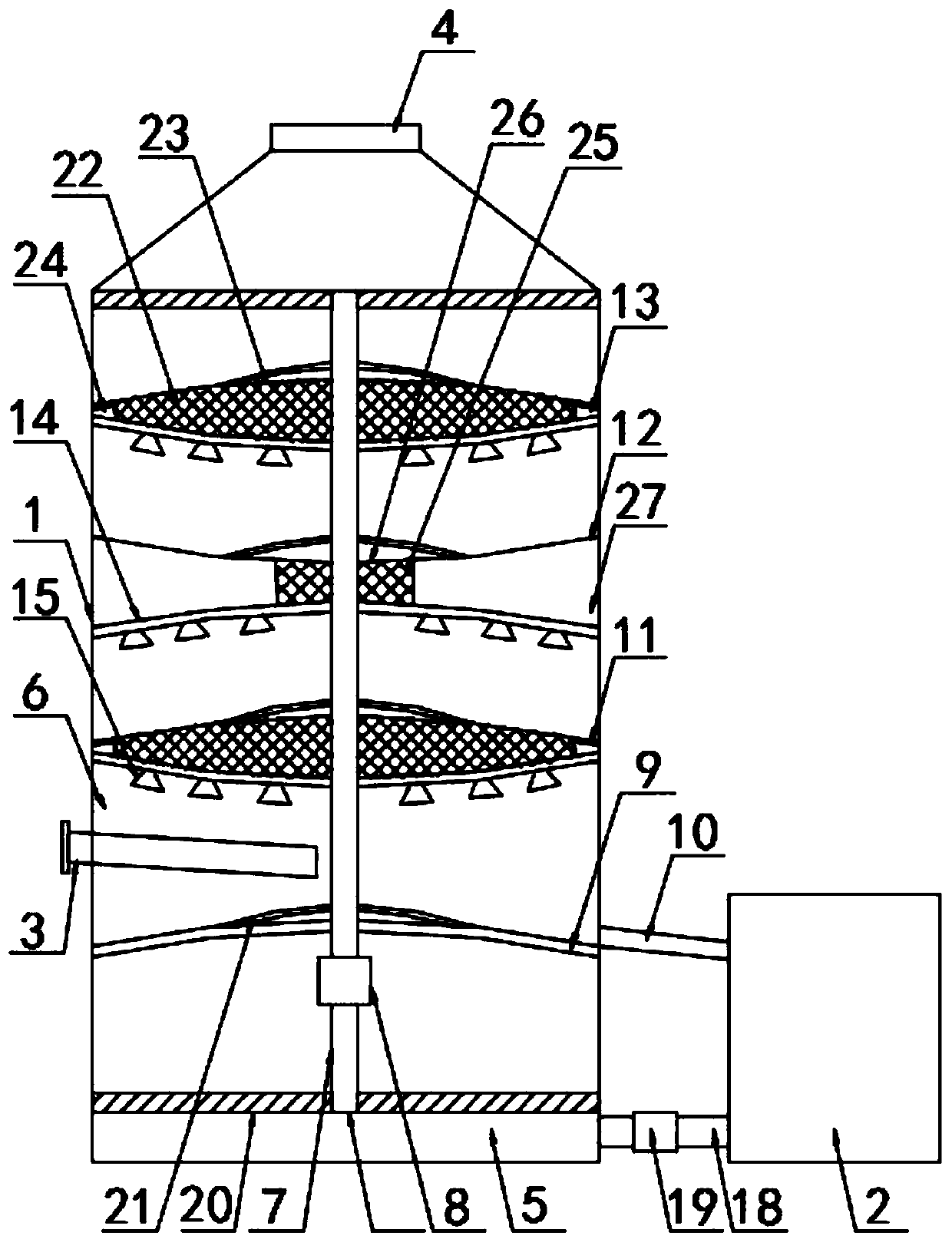

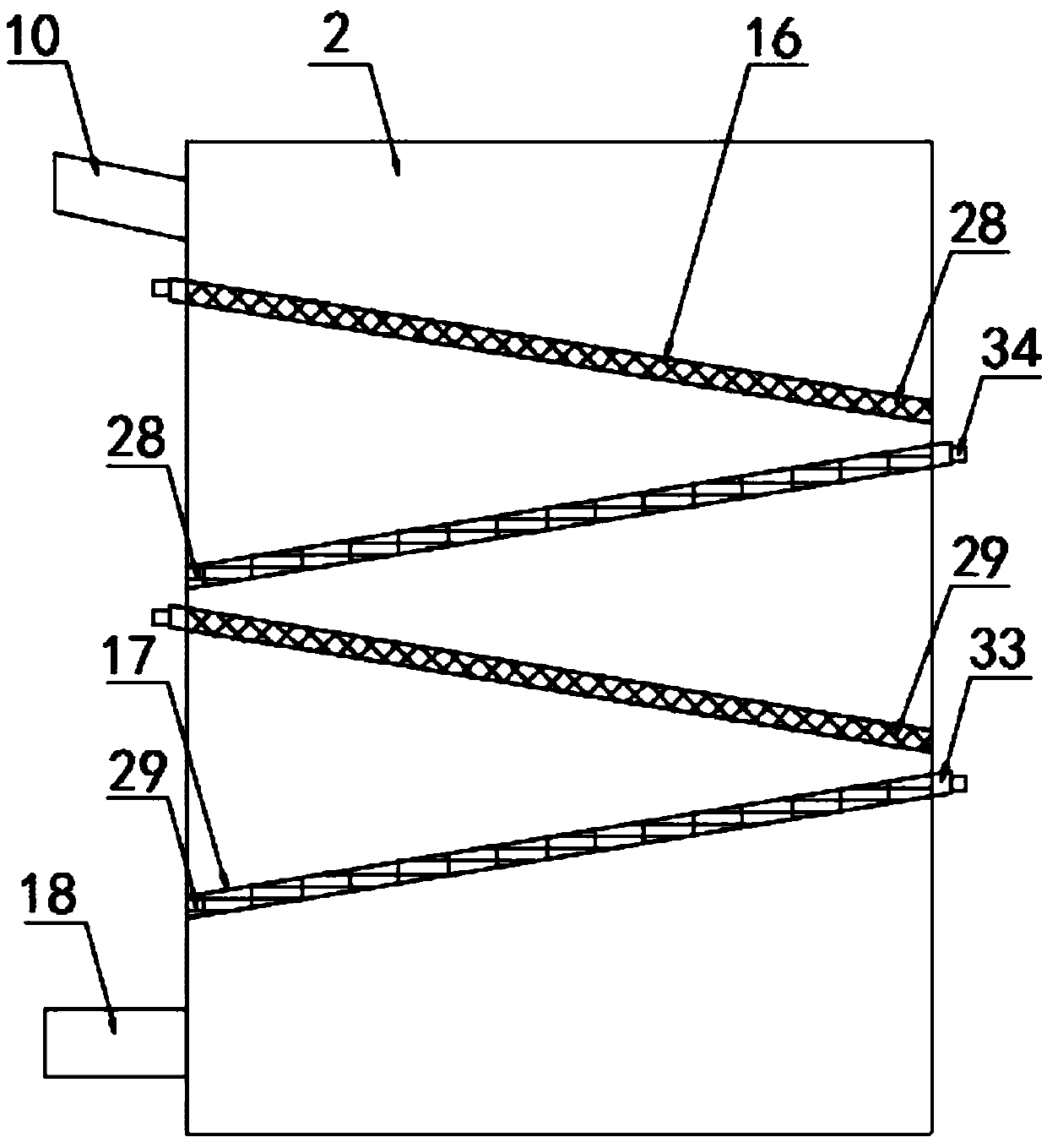

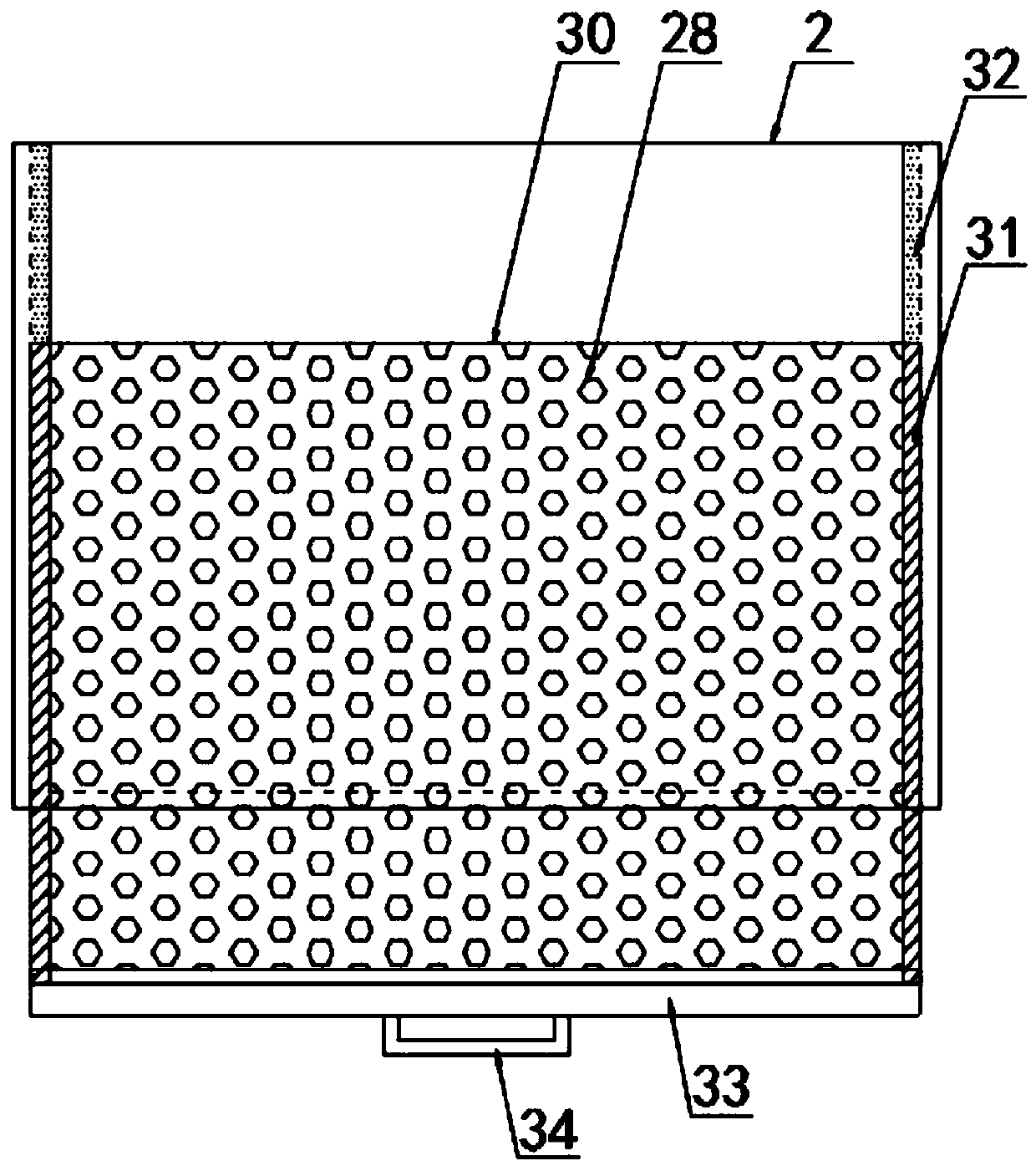

[0035] according to Figure 1-2The circulating water self-cleaning structure of a kind of scrubbing tower shown comprises scrubbing tower 1 and filtering device 2, described scrubbing tower 1 side is provided with inlet inclined pipe 3, and described scrubbing tower 1 top is provided with air outlet 4, so The inside of the washing tower 1 is provided with a clean water bin 5, the top of the clean water bin 5 is provided with a washing bin 6, and the inside of the washing bin 6 and the clean water bin 5 is provided with a suction pipe 7, and the water suction pipe 7 is provided with The first water pump 8, the top and bottom ends of the suction pipe 7 are provided with fixed rods 20, the fixed rods 20 are fixedly connected with the inner wall of the washing tower 1, the top of the suction pipe 7 is sealed, and the suction pipe 7 runs through the water outlet The plate 9, the first washing layer 11, the second washing layer 12 and the third washing layer 13 are arranged, the fir...

Embodiment 2

[0039] The present invention also provides a kind of circulating water self-cleaning process of washing tower, described specific steps are as follows:

[0040] Step 1: The exhaust gas enters the washing chamber 6 through the intake inclined pipe 3 and flows upwards. At this time, the first water pump 8 works, and the clean water inside the clean water chamber 5 is pumped out through the suction pipe 7 and passed through the nozzle 15 at the bottom of the distribution pipe 14 spray

[0041] Step 2: The exhaust gas passes through the first washing layer 11, the second washing layer 12, and the third washing layer 13 in sequence during its ascent, and contacts the water sprayed from the nozzle 15 at the bottom. The particles contained in the exhaust gas and water soluble The material is taken away by the water and flows down, and the exhaust gas is filtered through the first filler 22 and the second filler 25 during the upward flow process. Because of the setting of the annular ...

Embodiment 3

[0046] Different from Embodiment 2, the first filter group 16 can also be set inside the filter device 2, and the second filter group 17 is for standby. When cleaning, the second filter group 17 can be put into the filter device 2 earlier, and then The first filter group 16 is taken out so that the first filter group 16 and the second filter group 17 are used alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com