A kind of rich five-coordinate alumina and its synthesis method and application

A synthesis method, alumina technology, applied in chemical instruments and methods, alumina/hydroxide preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low single-atom catalyst loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

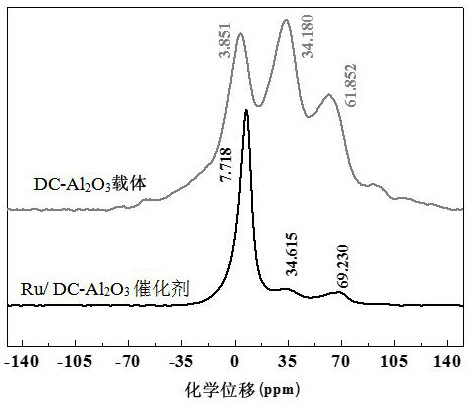

[0030] 37.5g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) with 25g glycine (C 2 h 5 NO 2 ) was dissolved in 100ml of deionized water to form a clear solution, and the clear solution was stirred and evaporated in a water bath at 70°C for 3.5 hours until it became viscous, and the resulting viscous jelly was placed in a round porcelain dish and placed in a microwave oven 800W microwave heating for 3min, then turn off the microwave to lower the temperature, after it cools down to room temperature naturally, put the microwave-heated product in a tube furnace, in an air atmosphere (air flow rate 100mL / min), from room temperature to 3 °C / min The temperature was raised to 400°C at a rate of min and fired at 400°C for 4h. After it is naturally cooled to room temperature, the product roasted in the tube furnace is taken out to obtain a five-coordinated alumina powder, which is denoted as DC-Al 2 o 3 .

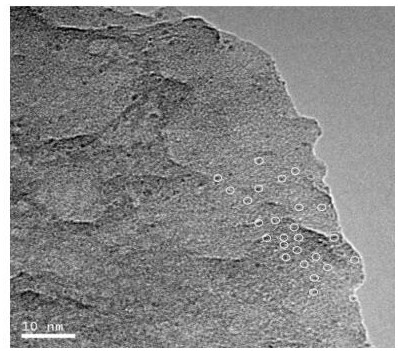

[0031] DC-Al 2 o 3 The support was impregnated in RuCl 3 In aqueous...

Embodiment 2

[0038] 37.5g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) with 32g citric acid (C 6 h 8 o 7 ) was dissolved in 100ml deionized water to form a clear solution, and the clear solution was stirred and evaporated in a water bath at 70°C for 4 hours until it became viscous, and the resulting viscous jelly was placed in a round porcelain dish and placed in a muffle furnace roasted at 500°C for 1 h, and then lowered the temperature. After it was naturally cooled to room temperature, the product roasted in the muffle furnace was placed in a tube furnace under an oxygen-nitrogen mixed gas atmosphere (oxygen-nitrogen mixed gas flow rate 100mL / min, the oxygen concentration in the oxygen-nitrogen mixed gas is 99%), the temperature is raised from room temperature to 450°C at a rate of 3°C / min and fired at 450°C for 4h. After it is naturally cooled to room temperature, the product roasted in the tube furnace is taken out to obtain a five-coordinate alumina powder, which is denote...

Embodiment 3

[0044] 37.5g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) with 15g oxalic acid (C 2 h 2 o 4 ) was dissolved in 100ml of deionized water to form a clear solution, and the clear solution was stirred and evaporated in a water bath at 70°C for 5 hours until it became viscous, and the resulting viscous jelly was placed in a round porcelain dish and placed in a tube furnace N at 20ml / min 2 Baking at 450°C for 2h under flow rate. Subsequently, the temperature was lowered, and after it was naturally cooled to room temperature, the round ceramic dish and the baked product were placed in another tube furnace together, under an air atmosphere (air flow rate 100mL / min), from room temperature to 3 °C / min. The temperature was raised to 400°C at a rate of min and fired at 400°C for 4h. After it is naturally cooled to room temperature, it is taken out to obtain a powder rich in five-coordinated alumina, which is recorded as TDC-Al 2 o 3 .

[0045] TDC-Al 2 o 3 Carrier impregn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com