A cleaning device for hemorheological instruments

A cleaning device and blood rheology technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of occupation of personnel's working time, water splashing, etc., and save the time of manual cleaning , to avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

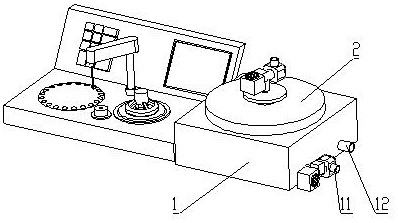

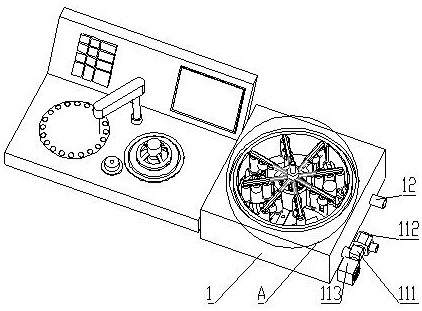

[0040] see figure 1 and figure 2 , the present invention provides a cleaning device for blood rheological instruments, including a base 1 provided with a cleaning chamber, a top cover 2 is provided on the top of the base 1, and a water inlet communicating with the cleaning chamber is provided on one side of the base 1 11 and the water outlet 12, the pipelines of the water inlet 11 and the water outlet 12 are all provided with solenoid valves, and the pipelines are controlled to open and close through the solenoid valves;

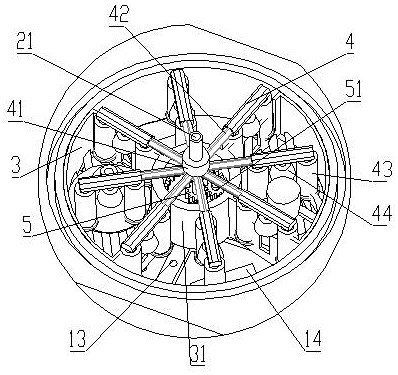

[0041] The cleaning chamber is rotated and connected to the cleaning pool 3. The cleaning pool 3 includes two parts that are separated and symmetrical; the bottom of the cleaning pool 3 is grid-shaped; The bottom plate is provided with a number of jet ports 13 for jetting water, and an ultrasonic vibrating plate 14;

[0042] The cleaning chamber is a cylindrical cavity, and the cleaning pool 3 includes two fan-shaped pool bodies symmetrically arranged. Th...

Embodiment 2

[0049] see Figure 1 to Figure 6 , On the basis of Embodiment 1, different from Embodiment 1, this device includes a base 1 provided with a cleaning chamber, a top cover 2 is provided on the top of the base 1, and a cleaning chamber is provided on one side of the base 1. The water inlet 11 and the water outlet 12 connected in the chamber are provided with electromagnetic valves on the pipelines of the water inlet 11 and the water outlet 12, and the opening and closing of the pipelines are controlled by the electromagnetic valves;

[0050] The cleaning chamber is rotated and connected to the cleaning pool 3. The cleaning pool 3 includes two parts that are separated and symmetrical; the bottom of the cleaning pool 3 is grid-shaped; The bottom plate is provided with a number of jet ports 13 for jetting water, and an ultrasonic vibrating plate 14;

[0051] The cleaning chamber is a cylindrical cavity, and the cleaning pool 3 includes two fan-shaped pool bodies symmetrically arran...

Embodiment 3

[0074] On the basis of Embodiment 2, the difference from Embodiment 2 is that the external port 21 is fixedly connected to the three-way valve 111 , and the lower end of the center column 41 is inserted into the upper end of the gear shaft of the driving wheel 5 . Such a connection mode does not need to disassemble the three-way valve 111 when picking up the top cover 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com