Novel fiber placement head

A new type of silk laying head technology, applied in the field of new silk laying head, can solve the problems of short life of cutter and chopping board, lower molding speed, poor molding quality, etc., and improve process adaptability, equipment accessibility, and response Time reduction, effect of reducing laying head size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

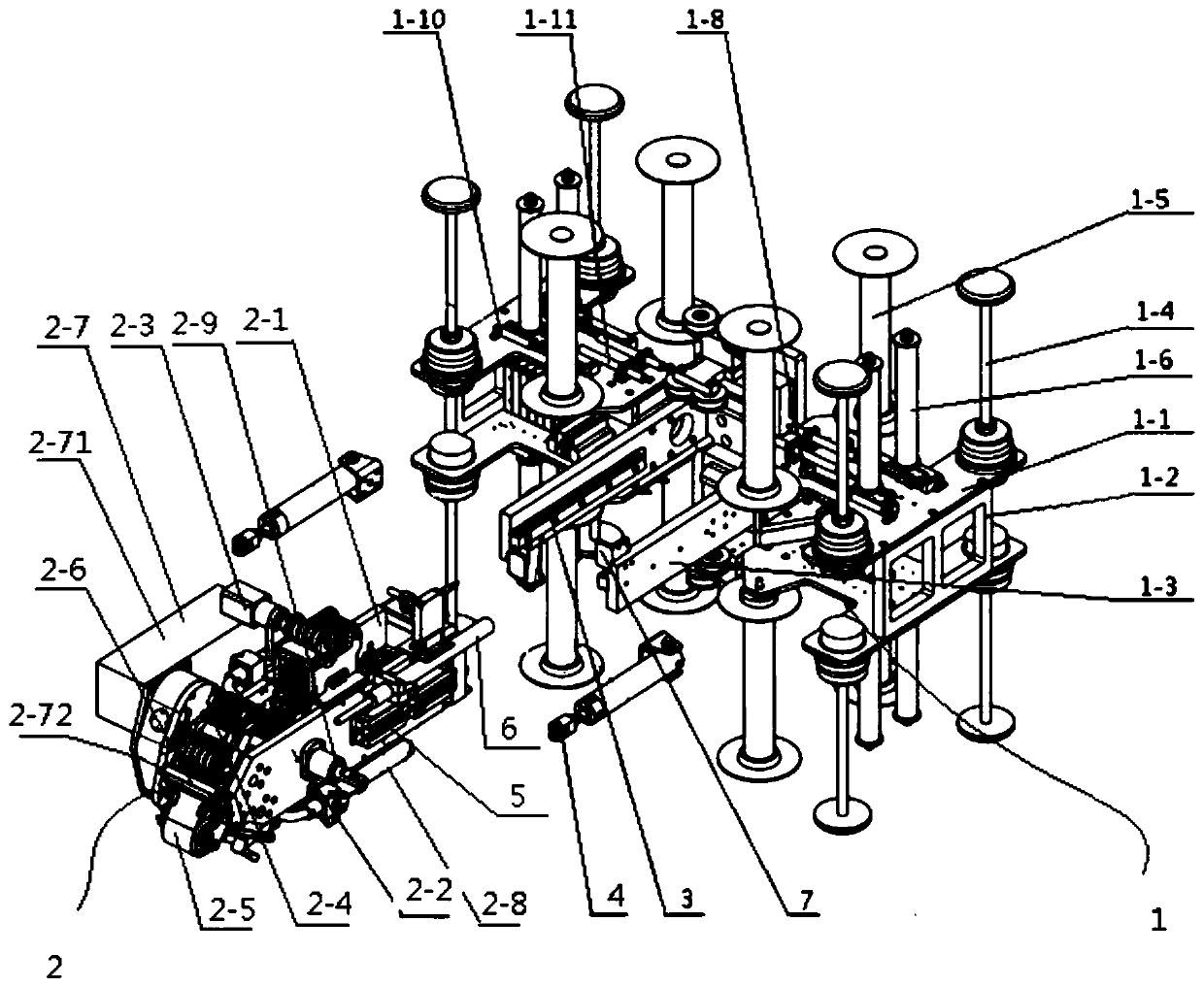

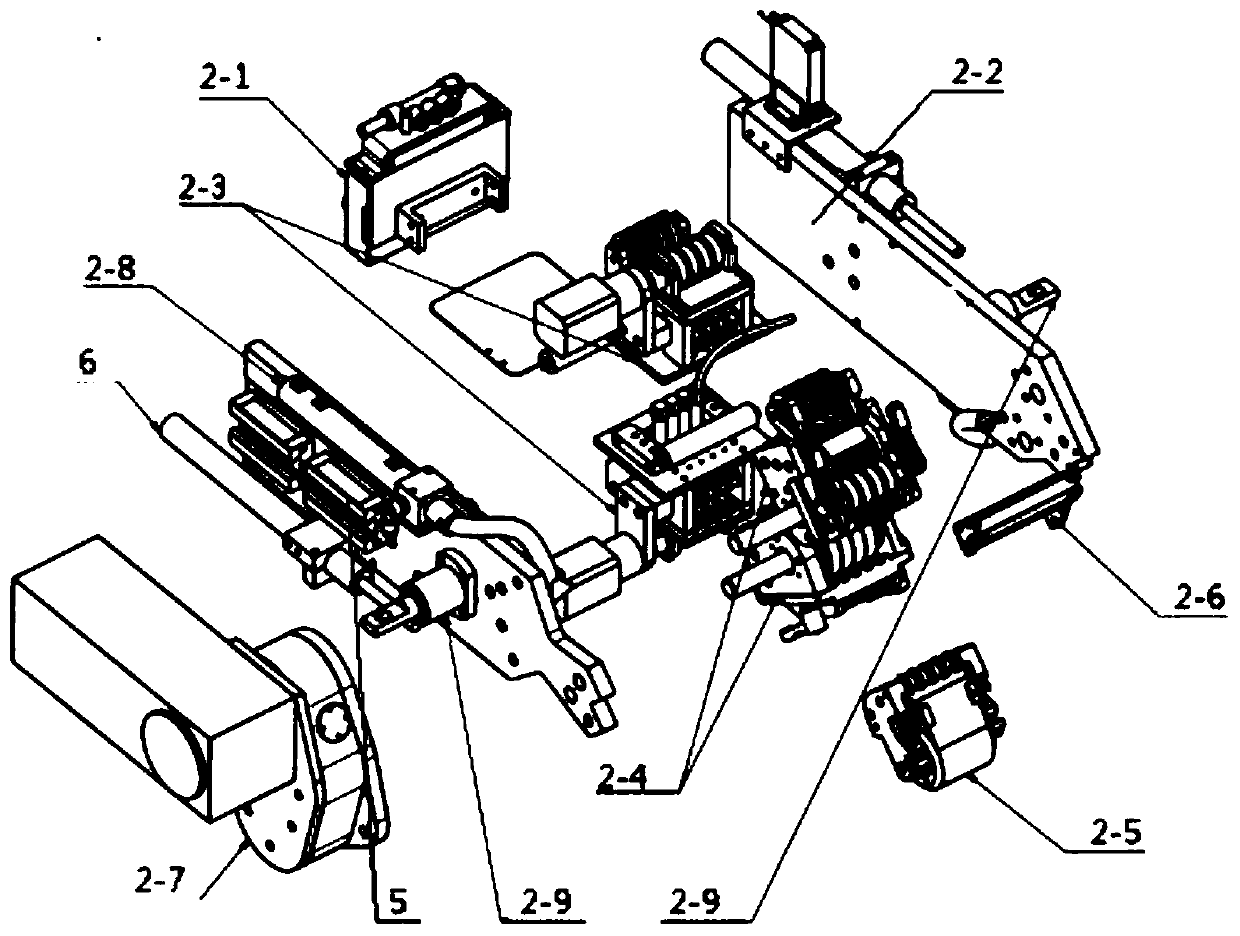

[0052] Embodiment 1, a new type of silk-laying head, two linear guide rails 3 are arranged in parallel on the yarn box 1, a slider 5 is installed on the floating mechanism 2 of the silk-laying head, and the floating mechanism 2 of the silk-laying head communicates with the The linear guide rail 3 is used in conjunction with one end of the pressing cylinder 4 connected with the yarn box 1, and the other end of the pressing cylinder 4 is connected with the floating mechanism 2 of the laying head, and the pressing cylinder 4 drives the floating mechanism 2 of the laying head to slide on the linear guide rail 3.

[0053] The laying head floating mechanism 2 includes: terminal mounting plate 2-1, vertical plate 2-2, tension reducing mechanism 2-3, tow actuating device 2-4, flexible pressure roller 2-5, heating lamp 2 -6. Driving mechanism 2-7, vortex tube 2-8 and compression cylinder hinged seat 2-9, vertical plates 2-2 are arranged on both sides of the terminal mounting plate 2-1, ...

Embodiment 2

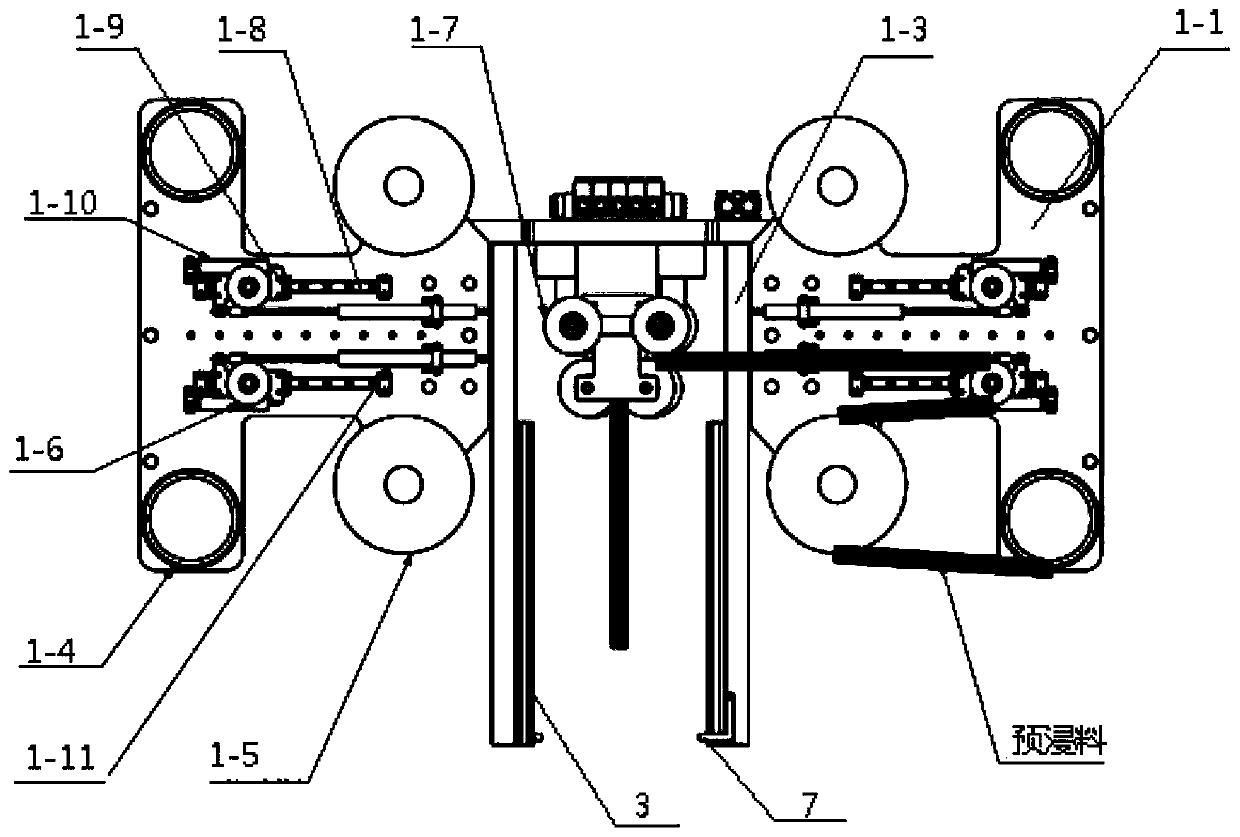

[0054] Embodiment 2, the yarn box 1 includes: a mounting plate 1-1, a connecting support plate 1-2, and a U-shaped connecting plate 1-3, and the left and right sides of the U-shaped connecting plate 1-3 are provided with two mutual Parallel installation boards 1-1, the other end of the installation boards 1-1 on the same side are connected by connecting support boards 1-2, each installation board 1-1 is provided with two yarn releasing and film collecting mechanisms, U-shaped connecting boards A slide rail 3 is arranged on the inner wall of 1-3, and one end of the pressing cylinder 4 is connected with the outer wall of the U-shaped connecting plate 1-3, and a limit stop 7 is installed on the U-shaped connecting plate 1-3, and the floating mechanism 2 of the laying head The output end of the buffer cylinder 6 is used in conjunction with the limit stopper 7. In this way, multiple yarn collection mechanisms are placed on the same mounting plate 1-1 to reduce the overall size and s...

Embodiment 3

[0055] Embodiment 3, the yarn collection mechanism includes: yarn unwinding shaft 1-4, film collection shaft 1-5, tension measurement shaft 1-6, yarn box guide wheel 1-7, measurement slide rail 1-8, measurement slide Block 1-9, tension spring 1-10 and resistance ruler 1-11, on the described mounting plate 1-1, yarn unwinding shaft 1-4, film collecting shaft 1-5 and measuring slide rail 1-8 are installed, measuring slide A measuring slider 1-9 is installed on the rail 1-8, a tension measuring shaft 1-6 is installed on the measuring slider 1-9, one end of the tension spring 1-10 is connected with the measuring slider 1-9, and the tension spring 1-10 The other end is connected to the mounting plate 1-1, the resistance scale 1-11 is fixedly installed on the mounting plate 1-1, the moving end of the resistance scale 1-11 is connected to the measuring slider 1-9, and the U-shaped connecting plate 1-3 is internally closed Yarn box guide wheels 1-7 are arranged at the end of the bobbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com