A kind of production technology of antibacterial environmental protection anti-counterfeiting aluminum foil paper

A production process, aluminum foil paper technology, applied in papermaking, fungicides, packaging paper, etc., can solve problems such as high cost, pollute the environment, complex recycling process, etc., and achieve the effect of saving cost and process, saving cost, and simple recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

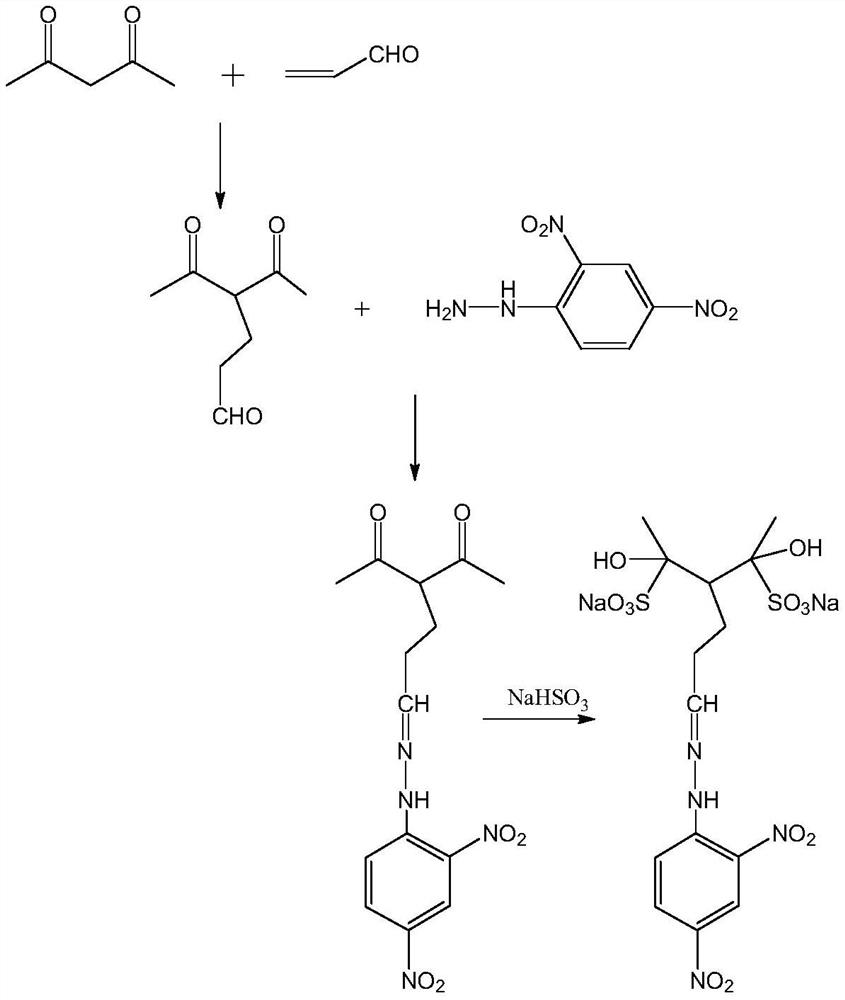

[0023] The specific preparation process of the antibacterial discoloration colloid is as follows:

[0024] Step 1: take by weighing 1kg pentanedione and add it to the reaction vessel, add 6L ethanol solution to it simultaneously, add dropwise sodium hydroxide to it after stirring and dissolving, adjust the pH=13 of the solution, then add 560g acrolein to the reaction vessel, The reaction was stirred at room temperature for 5-6 hours, then heated to 70 °C and evaporated for 4-5 hours to remove the ethanol solvent and unreacted acrolein. The adjusted product is extracted with ether, and the upper oil phase is removed for collection and then subjected to vacuum distillation to obtain dialdehyde diketone;

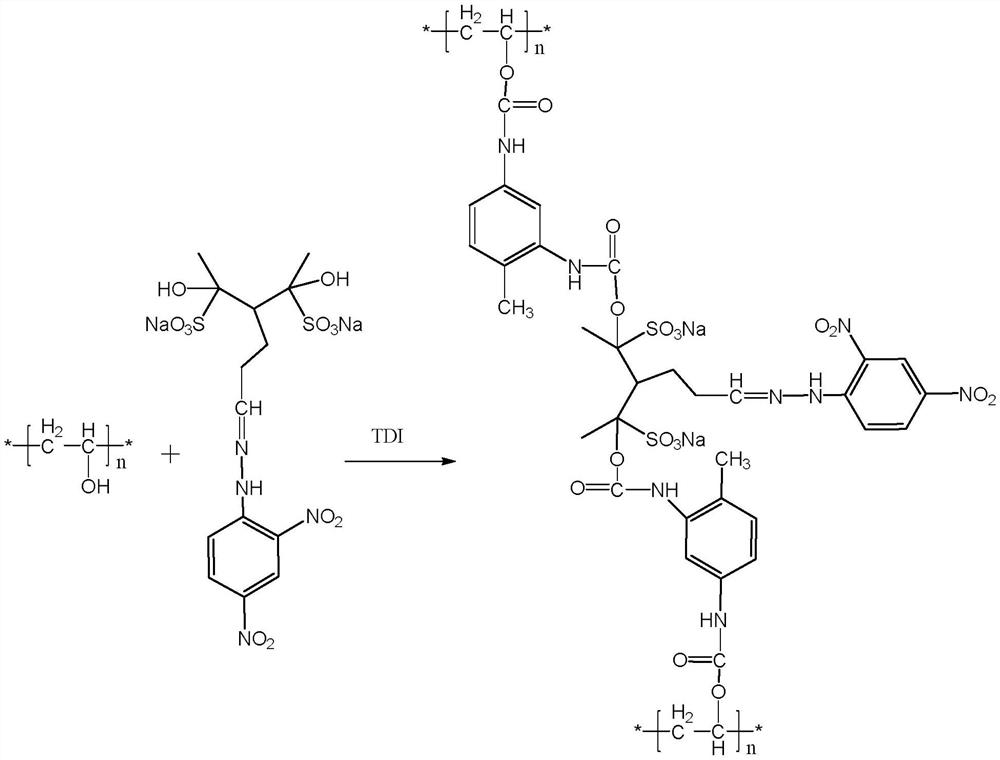

[0025] Step 2: Weigh 1kg of 2,4-dinitrophenylhydrazine and add it to 10L of acetic acid solution, cool down to 5-10°C and stir to dissolve, add 657g of the dialdehyde diketone prepared in step 1 dropwise to it, and control the rate of addition to be 3-4mL / min, after the dropwi...

Embodiment 2

[0035] The specific preparation process of the antibacterial discoloration colloid is as follows:

[0036] Step 1: take by weighing 1kg pentanedione and add it to the reaction vessel, add 6L ethanol solution to it simultaneously, add dropwise sodium hydroxide to it after stirring and dissolving, adjust the pH=13 of the solution, then add 560g acrolein to the reaction vessel, The reaction was stirred at room temperature for 5-6 hours, then heated to 70 °C and evaporated for 4-5 hours to remove the ethanol solvent and unreacted acrolein. The adjusted product is extracted with diethyl ether, and the upper oil phase is removed for collection and then distilled under reduced pressure to obtain dialdehyde diketone;

[0037] Step 2: Weigh 1kg of 2,4-dinitrophenylhydrazine and add it to 10L of acetic acid solution, cool down to 5-10°C and stir to dissolve, add 657g of the dialdehyde diketone prepared in step 1 dropwise to it, and control the rate of addition to be 3-4mL / min, after th...

Embodiment 3

[0041] The specific preparation process of the antibacterial discoloration colloid is as follows:

[0042] Step 1: Weigh 1kg of pentanedione and add it to the reaction vessel, add 6L of ethanol solution to it, stir and dissolve, add 4.5kg of saturated sodium sulfate solution, stir and react at room temperature for 5-7h, and then evaporate the solvent. Water and ethanol, the solid product is added to ethanol, stirred and mixed and filtered, the filtrate is collected and subjected to vacuum distillation to obtain sodium dihydroxysulfite;

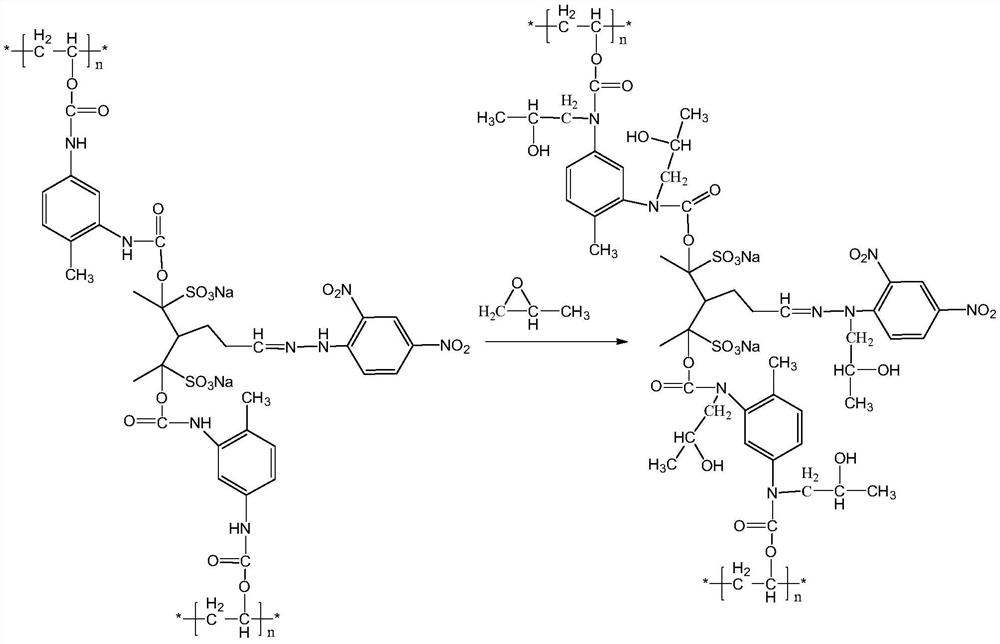

[0043] Step 2: Add 1kg of polyvinyl alcohol with a low degree of polymerization to 8L of hot water at 65-70°C and stir to dissolve, then add 0.431kg of the sodium dihydroxysulfite prepared in Step 2, stir and dissolve, and then dropwise into it Add 0.126kg of toluene diisocyanate, control the dripping speed to be 8-9mL / min, after the dripping is complete, the constant temperature stirring reaction is performed for 4-5h to obtain a viscous nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com