Discharging device for silicon rod in reduction furnace

A technology of a furnace device and a reduction furnace, which is applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of secondary cross-contamination of silicon rods and the decline in the quality of silicon materials, so as to improve production and operation efficiency, save costs, reduce The effect of human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

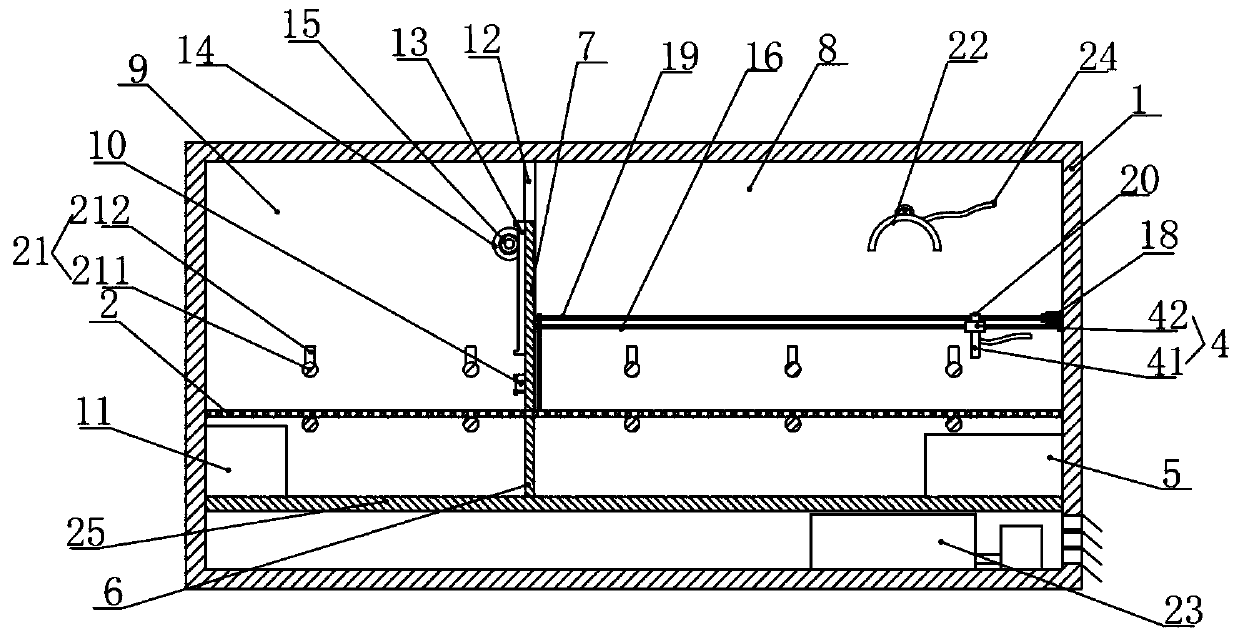

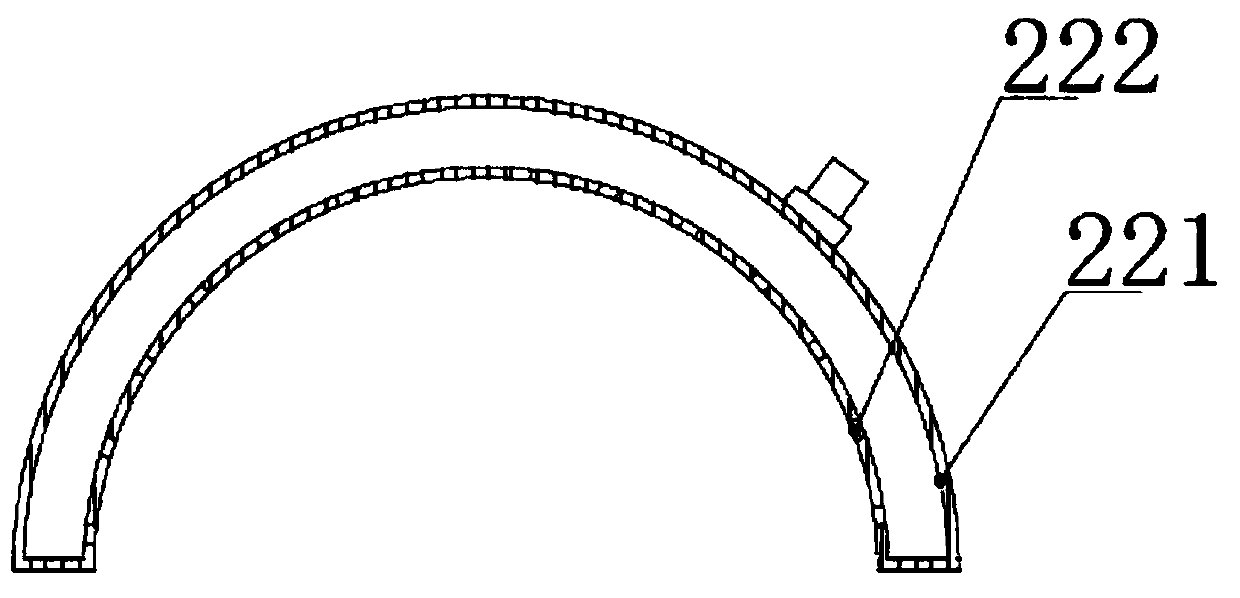

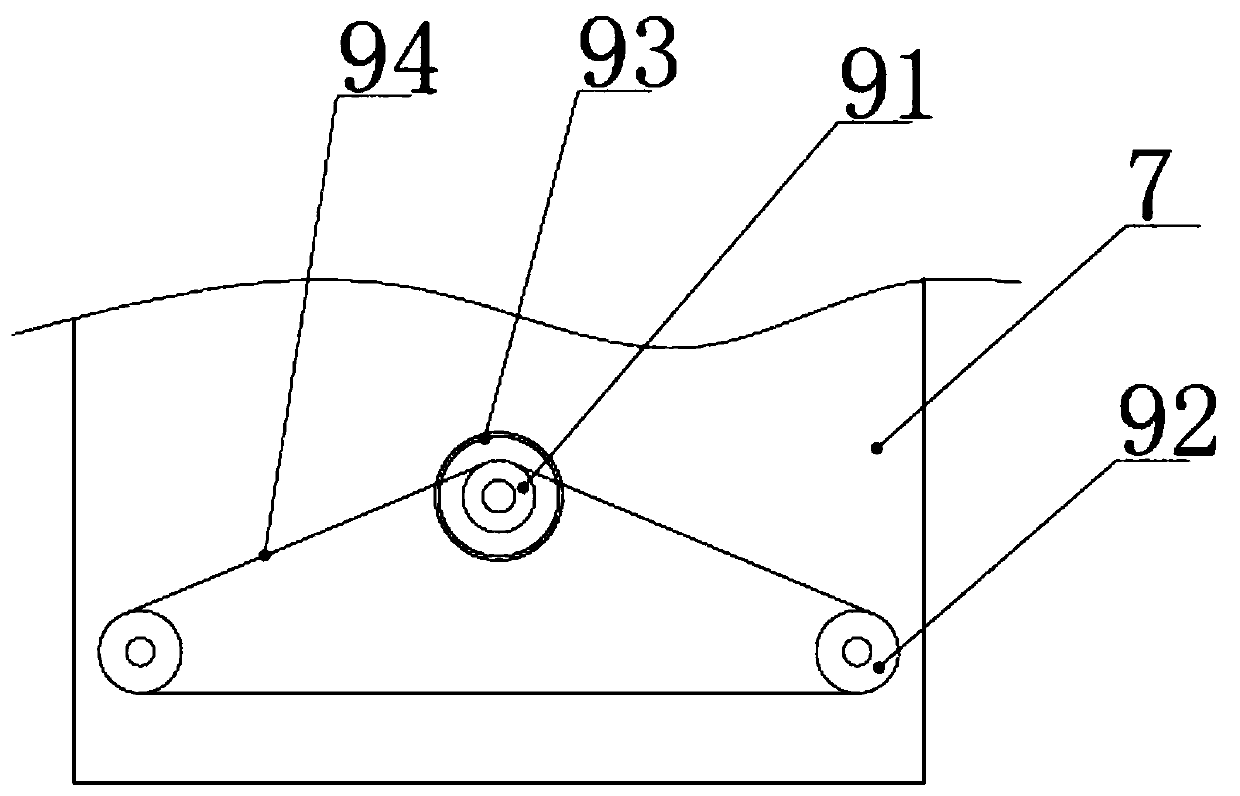

[0031] Figure 1 to Figure 5 Shown is a reduction furnace silicon rod tapping device provided by the present invention, which includes a box 1 with a switch door; the box 1 is equipped with a holding mechanism for placing silicon rods and a device for purging silicon rods. A purging device 4; a dust suction device 5 is also installed in the box body 1 .

[0032] The opening and closing door on the box body 1 is located on one or more sides of the box body 1, and the opening and closing door is directly hingedly mounted on the box body 1. In order to facilitate the observation of the situation in the box body 1, the opening and closing door can be A transparent glass window is installed on the top to facilitate people to observe the purging of the silicon rods; in order to facilitate the handling and pushing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com