Flame-retardant resin composition and insulated wire

A technology of resin composition and flame retardancy, which is applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., and can solve the problems that the flame retardancy of resin compositions cannot be fully improved

Active Publication Date: 2019-10-08

株式会社博迈立铖

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, only the addition of metal hydroxides still cannot suf

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

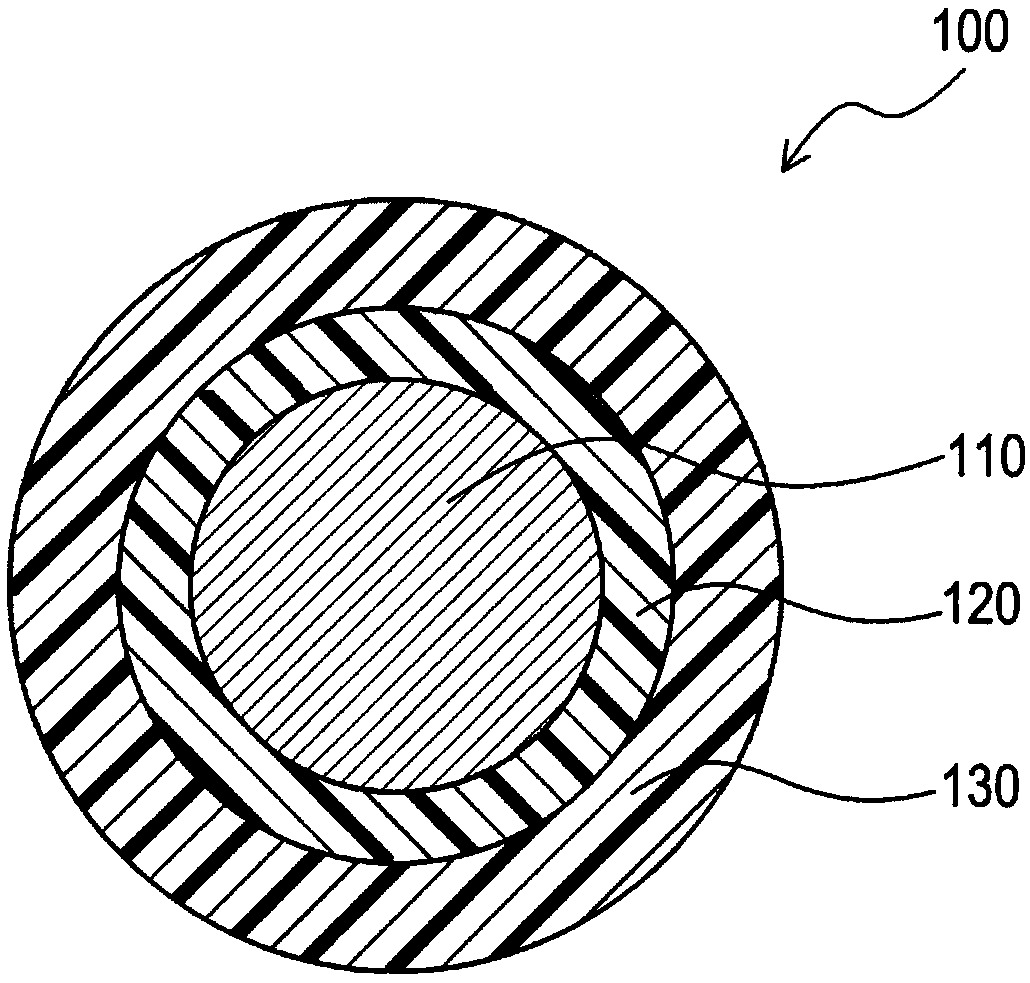

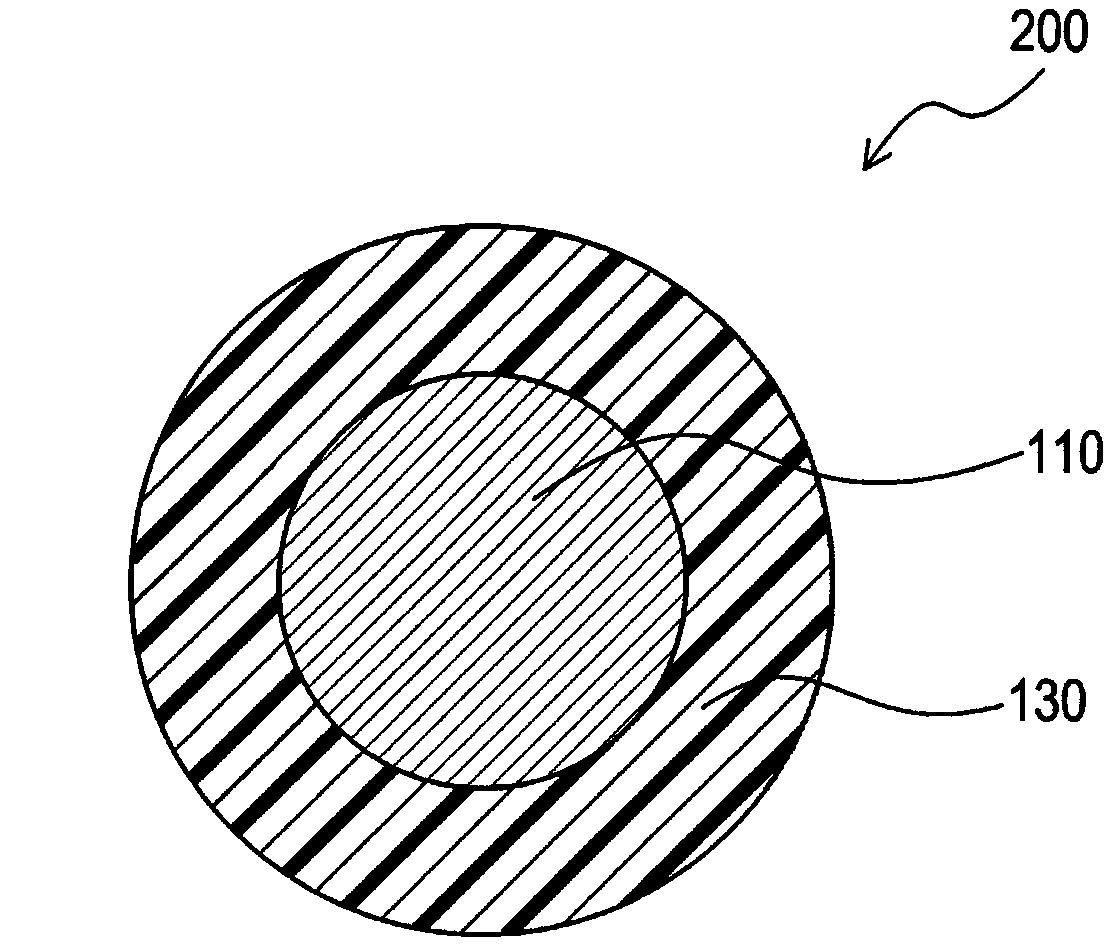

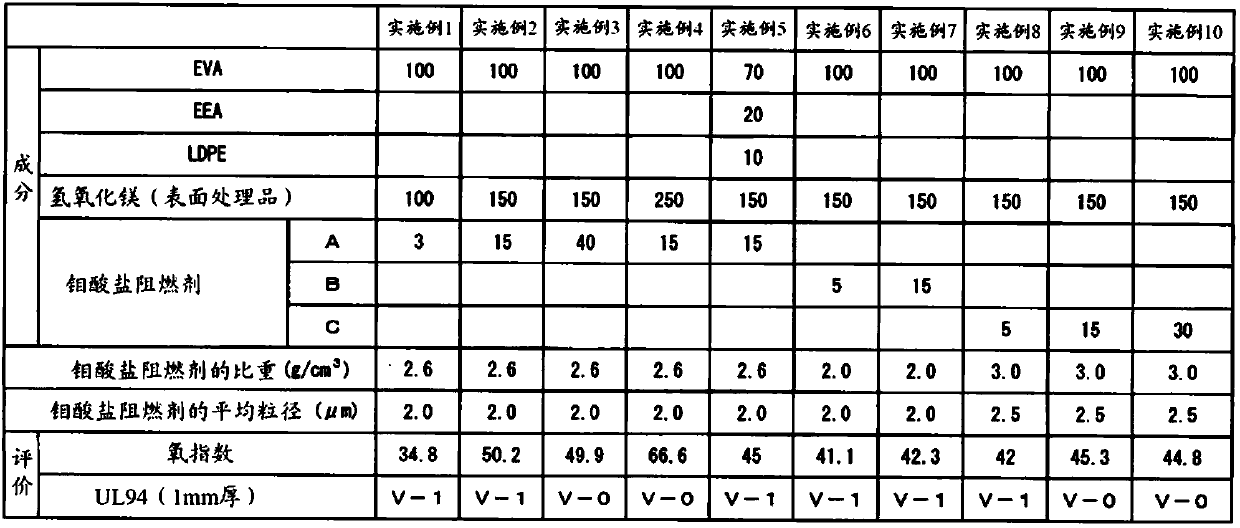

The present invention provides a flame-retardant resin composition having high flame retardancy and an insulated wire. The flame-retardant resin composition contains an olefin-based resin, a molybdateflame retardant, and a metal hydroxide. Content of the said molybdate flame retardant is 100 mass parts or more and 40 mass parts or less with respect to the said olefin resin. The specific gravity of the above molybdate flame retardant is below 4.0 g / cm3. The average particle size of the above molybdate flame retardant is 2.5 mum or less. The molybdate flame retardant preferably contains zincmolybdate. The molybdate flame retardant is preferably particles containing inorganic fine particles and zinc molybdate supported on the surface of the inorganic fine particles.

Description

technical field [0001] The present disclosure relates to a flame-retardant resin composition and an insulated wire. Background technique [0002] In order to improve the flame retardancy of the resin composition, a flame retardant is added to the resin composition. As flame retardants, metal hydroxides are used. Magnesium hydroxide, aluminum hydroxide, etc. are mentioned as a metal hydroxide. However, the flame retardancy of the resin composition cannot be sufficiently improved only by adding the metal hydroxide. Patent Document 1 discloses that magnesium hydroxide and the like are used in combination with molybdate as a flame retardant added to a resin composition. [0003] prior art literature [0004] patent documents [0005] Patent Document 1: Japanese Patent No. 5993264 Contents of the invention [0006] The problem to be solved by the invention [0007] Even with the technology disclosed in Patent Document 1, the flame retardancy of the resin composition is s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C08L23/08C08L23/06C08K9/00C08K3/22C08K3/24H01B3/44

CPCC08L23/0853C08K9/00C08K3/22C08K3/24H01B3/441C08K2003/2224C08L2201/02C08L2203/202C08L23/06

Inventor 牛渡刚真远藤正智

Owner 株式会社博迈立铖

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap