Blast furnace shutdown method and spray gun device for anatomical research

A technology of blast furnace and spray gun, which is applied in the field of blast furnace anatomy research, achieves good application prospects and is convenient for research and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

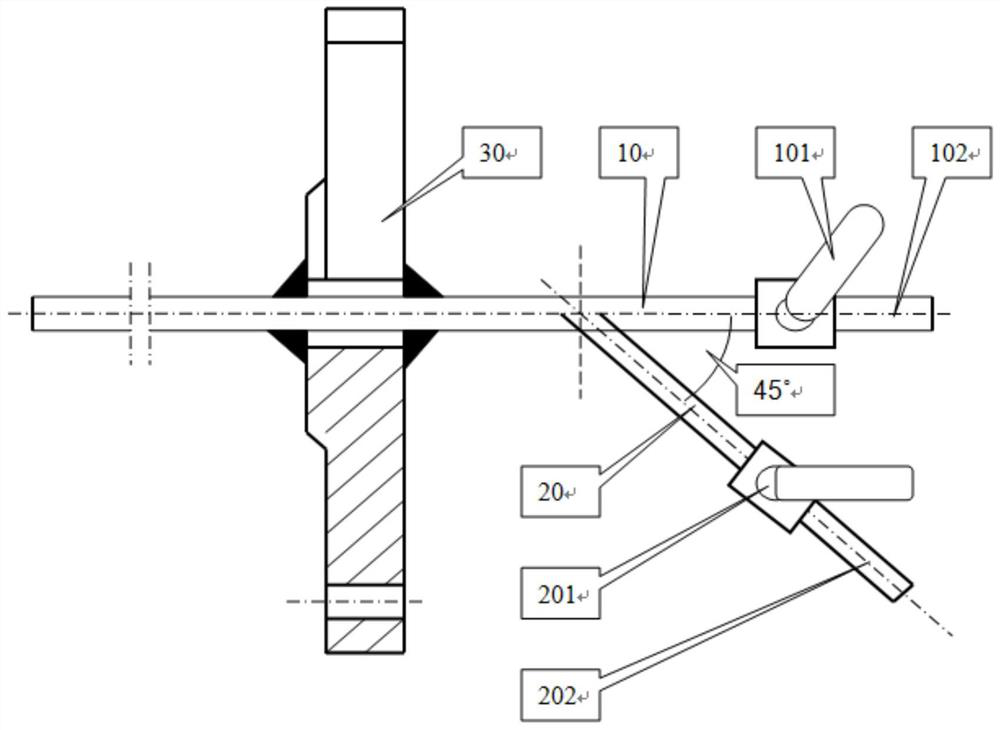

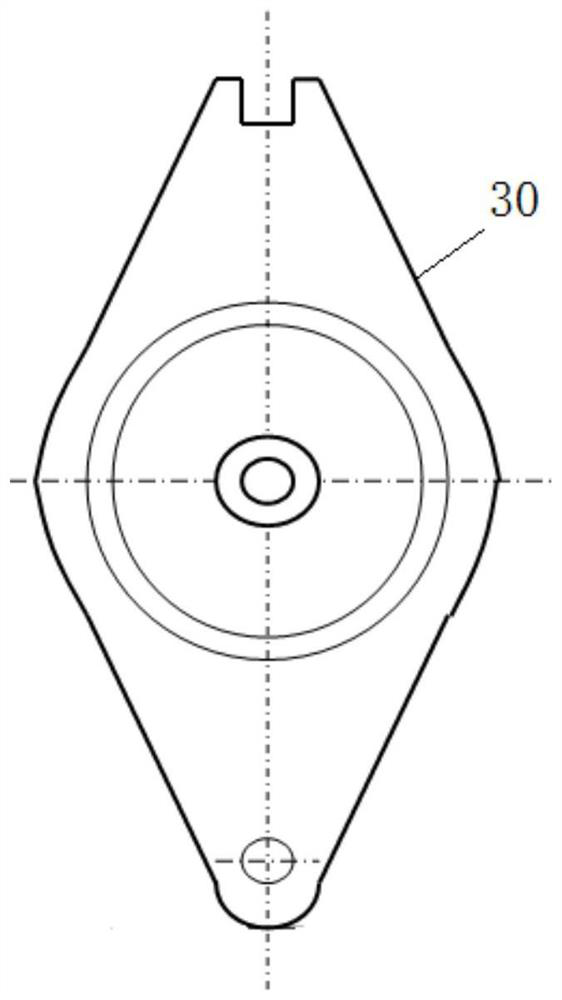

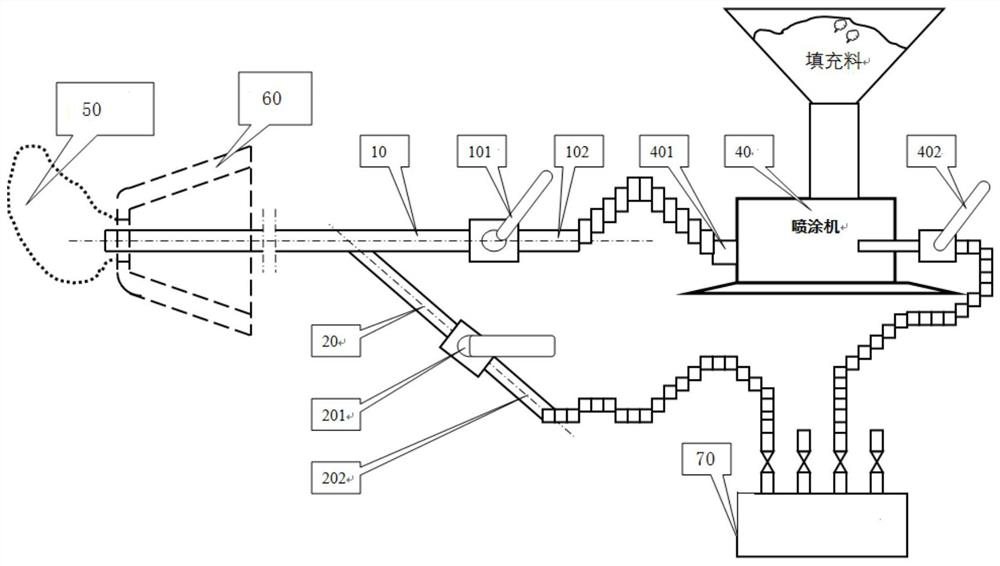

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0022] The shutdown method for blast furnace anatomical research of the present invention comprises the following steps: 1) designing and manufacturing a spray gun device for spraying filling material into the blast furnace tuyere swirl area; After the installation of the tuyere and spray gun device, the blast furnace will be re-aired; 3) The temperature of the blast furnace withdrawal air should ensure that the theoretical combustion temperature in front of the tuyere is not higher than the melting point temperature of the filler; 5) Effectively cut off the gas after the blast furnace shuts down, and the blast furnace cooling equipment maintains normal cooling; 6) Ventilate N2 gas into the blast furnace to cool the charge; 7) As the temperature of the furnace wall continues to descend, drill I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com