Warping touch screen operation box mounting structure of sectional warping machine

A technology for sectional warping machines and installation structures, which can be applied to warping machines, other manufacturing equipment/tools, textiles and papermaking, etc. It can solve the problems of unfavorable car workers to check and monitor information, long distances, and increased labor intensity of operators. , to avoid interference with yarn running, reduce labor intensity, and facilitate data input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

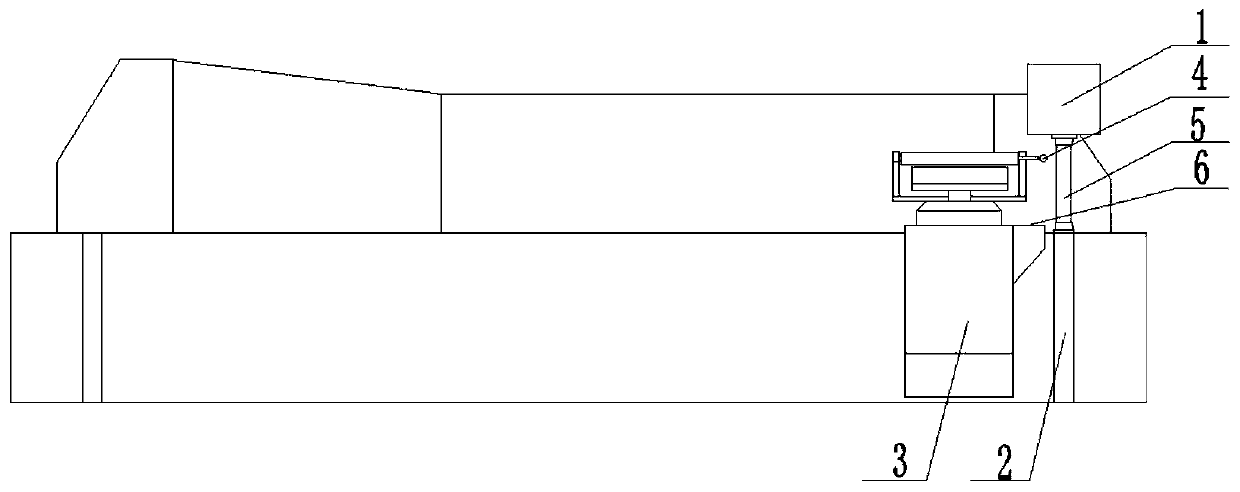

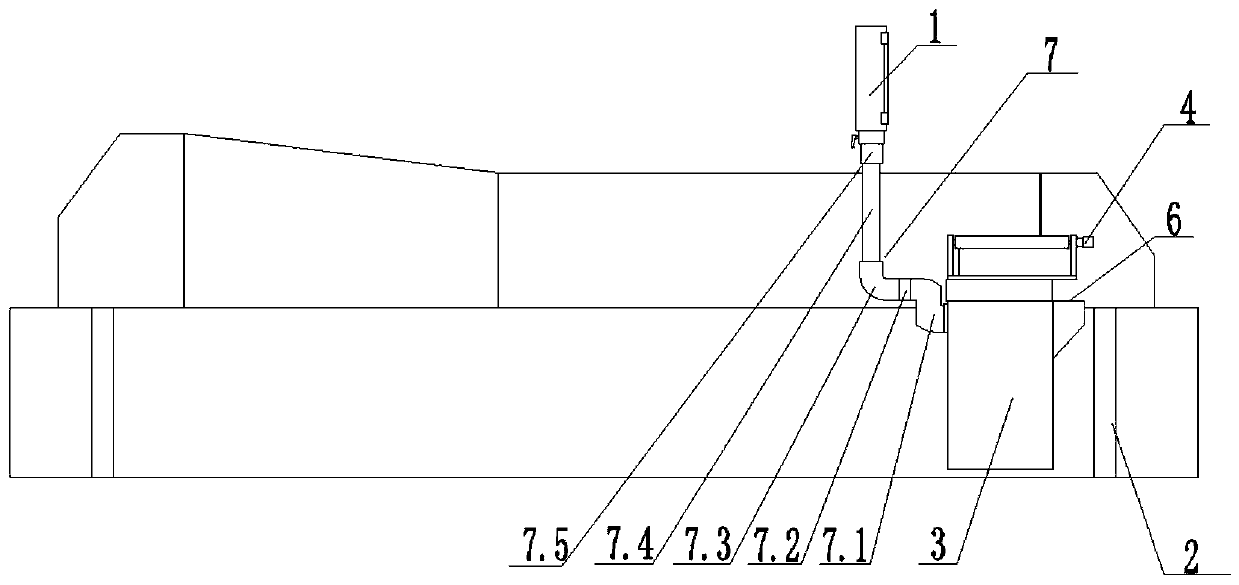

[0026] See figure 2 , The present invention relates to a section warping machine warping touch screen operation box installation structure, including a warping table 3, one side of the warping table 3 is provided with a button operation panel 6, and the other side of the warping table 3 A warping touch screen operation box 1 is suspended, and the warping touch screen operation box 1 is arranged opposite to the button operation panel 6;

[0027] The warping touch screen operation box 1 and the warping table 1 are connected by a cantilever assembly 7;

[0028] The cantilever assembly 7 includes a horizontal wall base 7.1, a horizontal connecting pipe 7.2, an upwardly bent right-angle elbow 7.3, and an upright support rod 7.4 that are connected in sequence, and the horizontal wall base 7.1 is rotatably connected with the side wall of the warping table 1. , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com