Offshore carbon fiber wind power blade lightning protection system

A lightning protection system and offshore wind power technology, applied in wind power generation, wind turbines, machines/engines, etc., can solve the problems of carbon fiber blade main beam being struck by lightning, uneven current distribution of lightning protection system, heat accumulation, etc., and achieve current conduction The effect of uniform distribution, avoiding local breakdown, and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

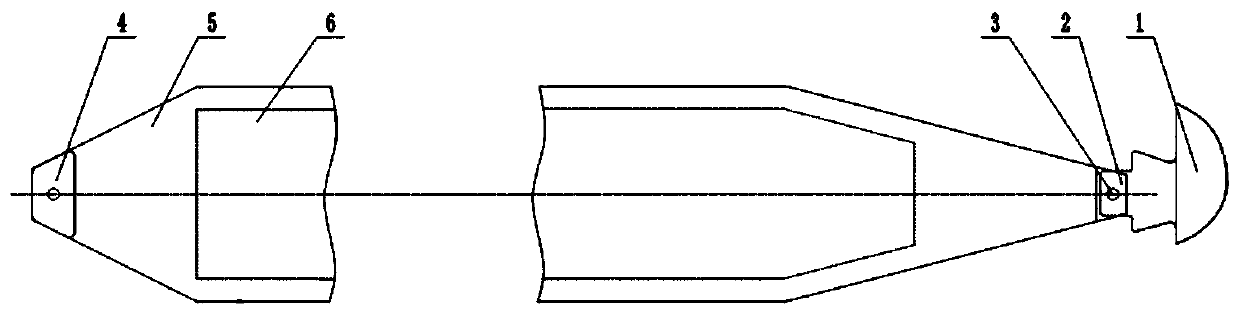

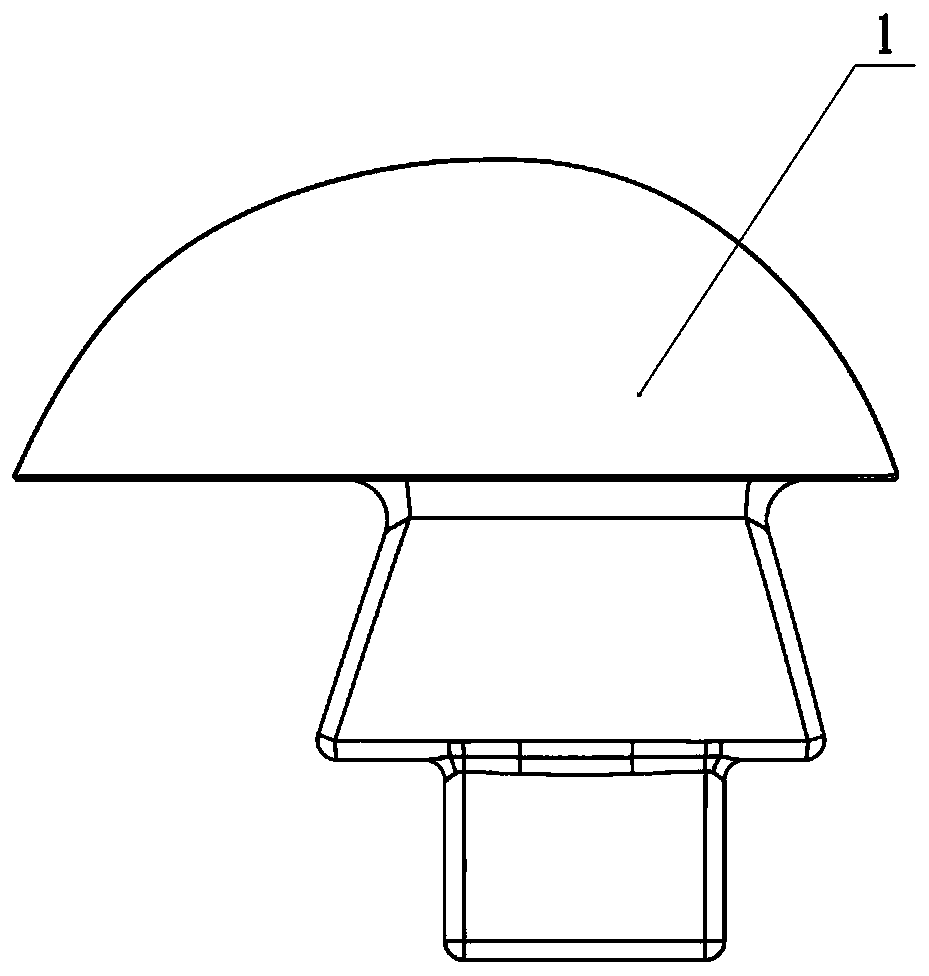

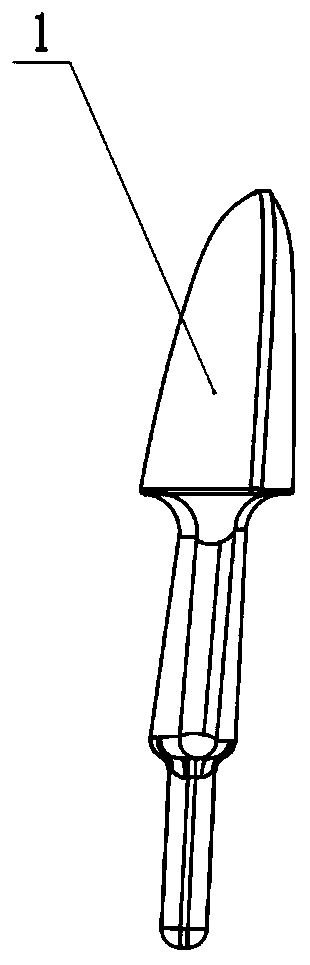

[0030] Basic as attached figure 1 , figure 2 , image 3 Shown: a lightning protection system for offshore carbon fiber wind power blades, including a blade tip lightning receptor 1, a metal mesh 5, a number of conductive plates, conductive bolts 3 and wires, the conductive plates include two pairs of blade root conductive plates 4 and two pairs of Blade tip conductive plate 2, combined with Figure 8 As shown, the blade tip air receptor 1 and the blade tip conductive plate 2 are fixed on the blade tip and connected by conductive bolts 3, combined with Figure 9 , Figure 10 As shown, the blade root conductive plate 4 is fixed on the blade root, and the blade root conductive plate 4 is connected to the conductive bolt 3 . The metal edges and corners of the conductive plate are rounded.

[0031] Metal mesh 5 is copper mesh or aluminum alloy mesh (preferably copper mesh in the present embodiment), and metal mesh 5 is covered on blade main beam 6, and metal mesh 5 is positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com